Method for integrally sealing and separating gas extraction drilled hole in coal seam

A technology for drilling and coal seam gas drainage, which is applied in the direction of gas discharge, sealing/isolation, mining equipment, etc., and can solve the problem of low gas drainage concentration, poor sealing quality of gas drainage drilling holes, and inability to guarantee the drainage effect To achieve the effect of improving the concentration of gas drainage, good promotion value and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

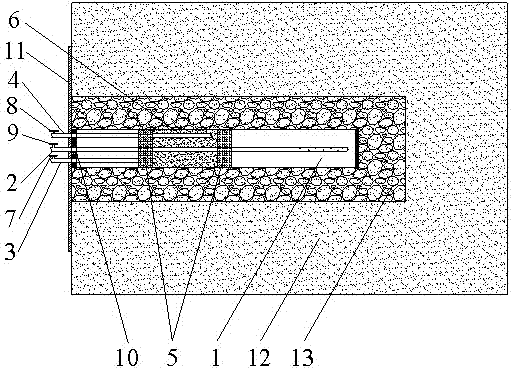

[0015] The coal seam gas drainage drilling and sealing integrated hole sealing method of the present invention: first construct a gas drainage drilling 1 from the drilling site to the pre-extraction area, such as the gas drainage drilling 1 depth 50m, aperture Φ113mm, after feeding the gas The gas drainage pipe 2 in the drainage borehole 1 is wrapped with 2-4 polyurethane sealing bags 5 at a distance of 15-20m from the orifice, and then wrapped with tape at a distance of 5-6m from the gas drainage pipe 2 from the orifice 2-4 polyurethane sealing bags 5, where the polyurethane sealing bag 5 should be no less than 5m away from the front end of the gas drainage pipe 2; at the same time, fix the slurry on the upper part of the gas drainage pipe 2 at a distance of 5~6m from the orifice Pipe 4, fixed grouting pipe 3 at the bottom, that is, gas extraction pipe 2, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com