Cascade pump device

A pump device and cascade technology, which is applied to the pump device, the pump, the components of the pumping device for elastic fluid, etc., can solve the problem of increasing the installation space of the cascade pump device, and achieve the effect of restraining the installation space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

other Embodiment approach

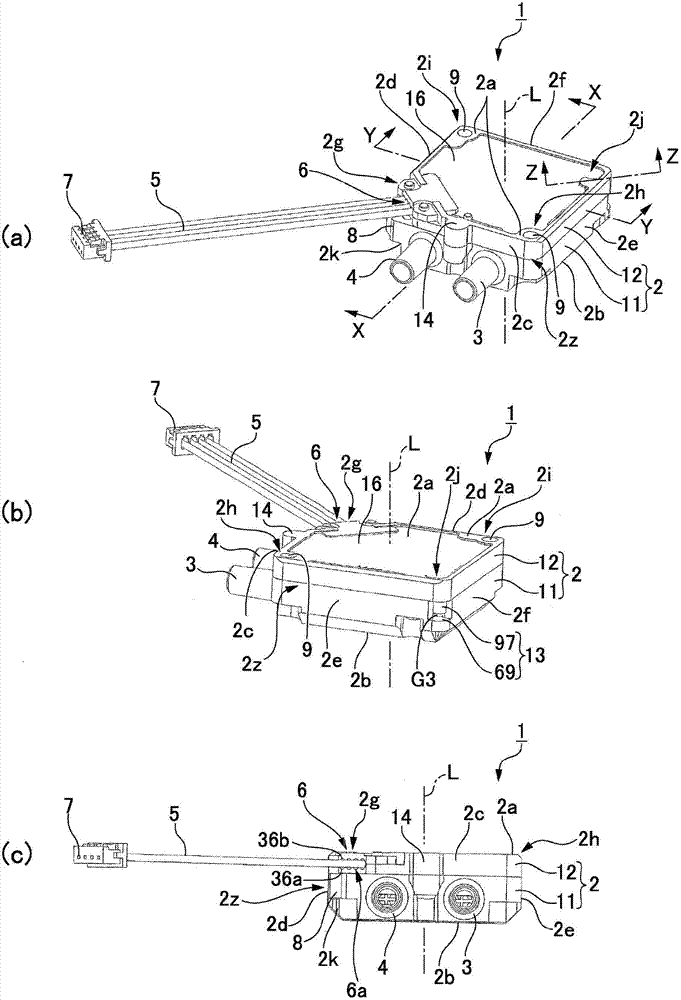

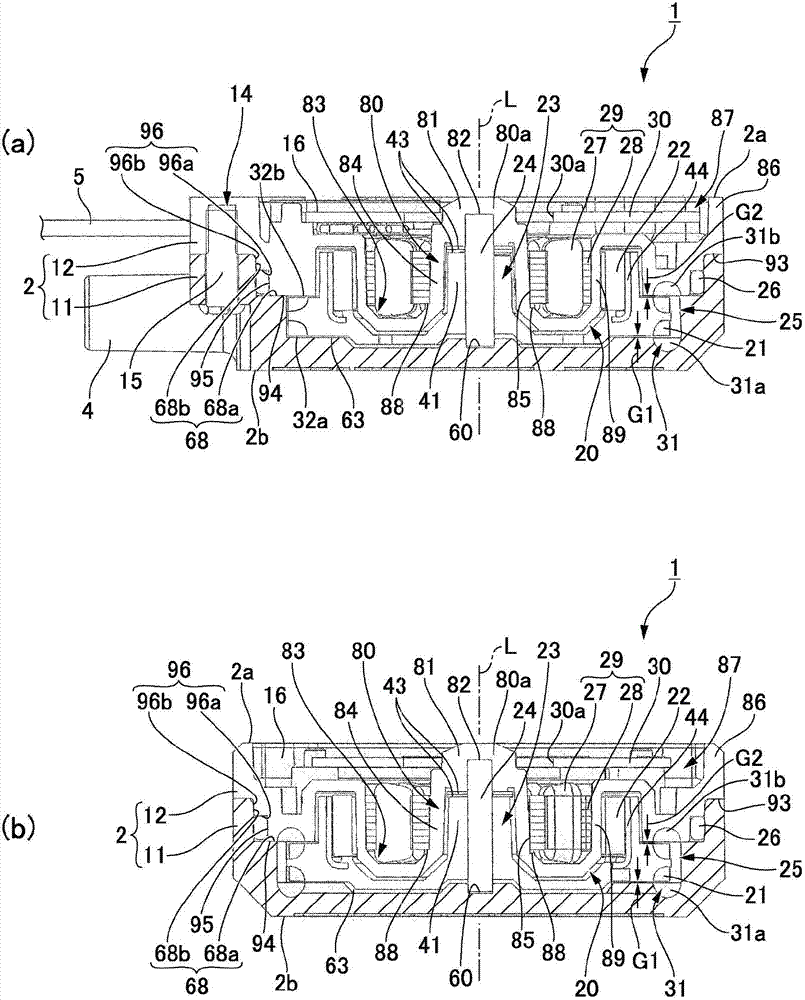

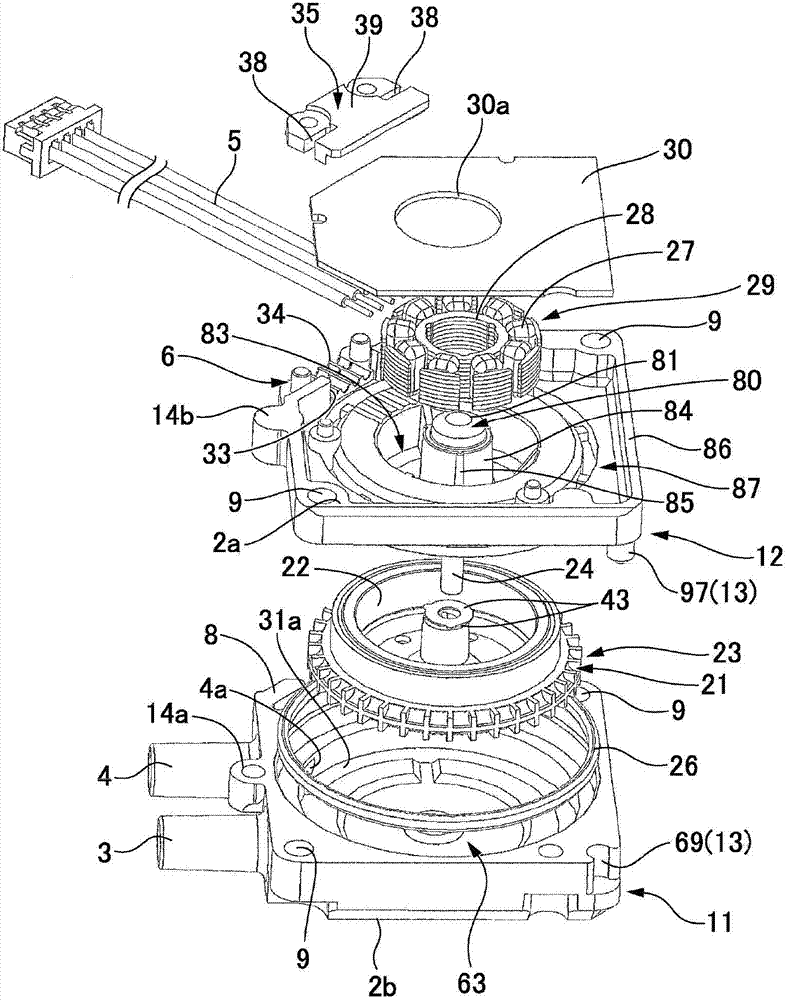

[0216] In the above example, the pump casing 2 has a square prism shape, but the pump casing 2 can also be formed in a cylindrical shape, a triangular prism shape, a pentagonal prism shape, a hexagonal prism shape, or a polygonal prism shape. Even in the case of the above-mentioned shape, if the suction pipe and discharge pipe extending in the same direction parallel to each other, and the wire extraction part are provided between the two end faces located at both ends of the pump casing in the axial direction, the wire extraction guide If the angle formed by the leading direction D1 of the part and the protruding direction of the suction pipe and the discharge pipe is less than 90°, when the cascade pump unit is installed on an external device, the suction pipe and the discharge pipe can protrude on the side of the pump casing. Provide a space for routing piping such as hoses connected to the suction pipe and discharge pipe, and a space for routing lead wires drawn from the pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com