Vehicle suspension arm

A suspension arm and vehicle technology, which is applied to vehicle springs, vehicle components, and cantilevers mounted on pivots, etc., can solve the problems of wasting materials and difficult forming, and achieve the effects of being beneficial to cost, simple in shape, and reducing manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

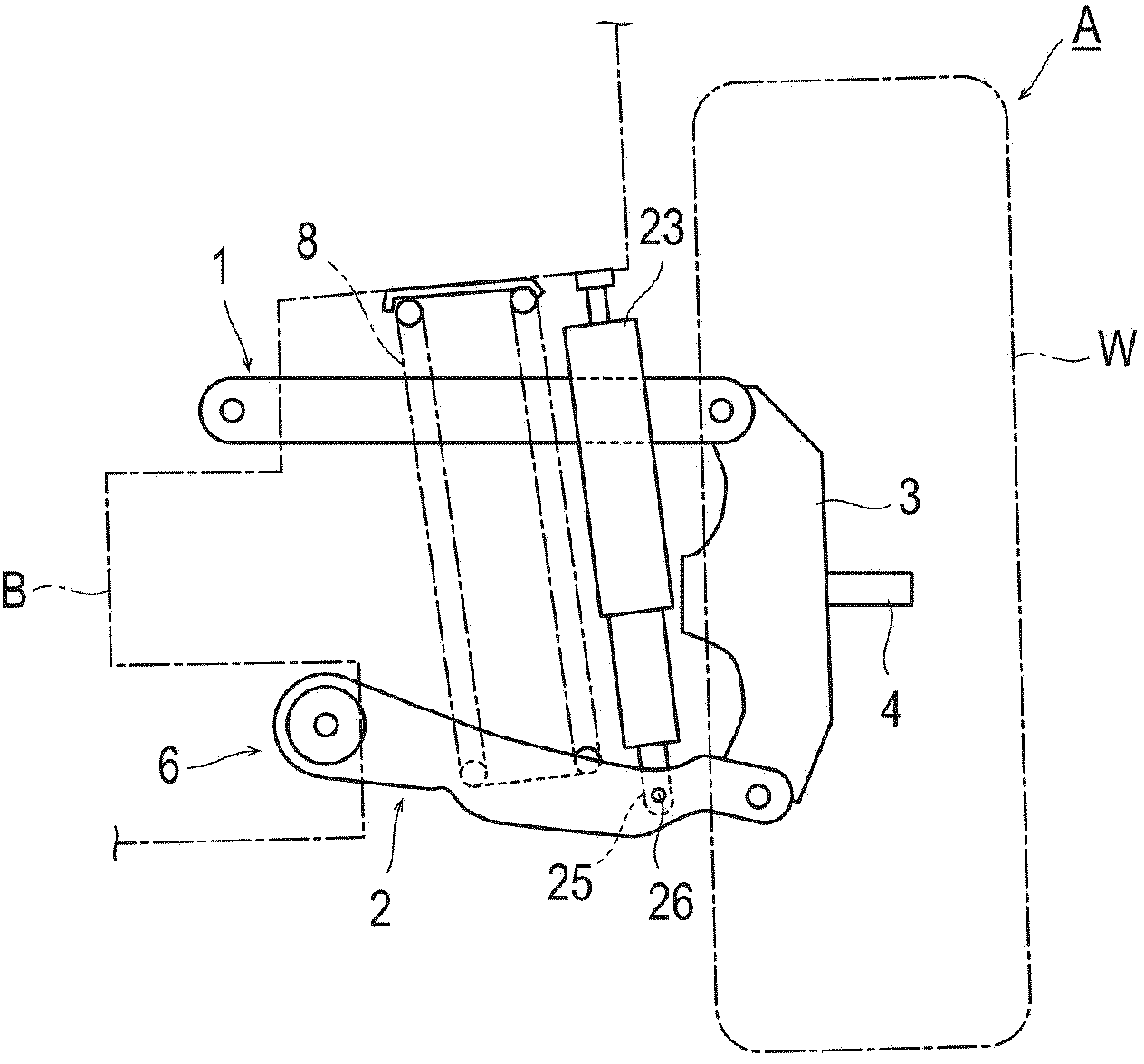

[0030] Such as figure 1 As shown, the suspension of this embodiment has an upper arm 1 and a lower arm 2 . One end of these arms 1 and 2 is connected to the vehicle body side B, and the other end is connected to a knuckle 3 on the shaft A side. In addition, reference sign "W" in a drawing is a wheel, and "4" is an axle.

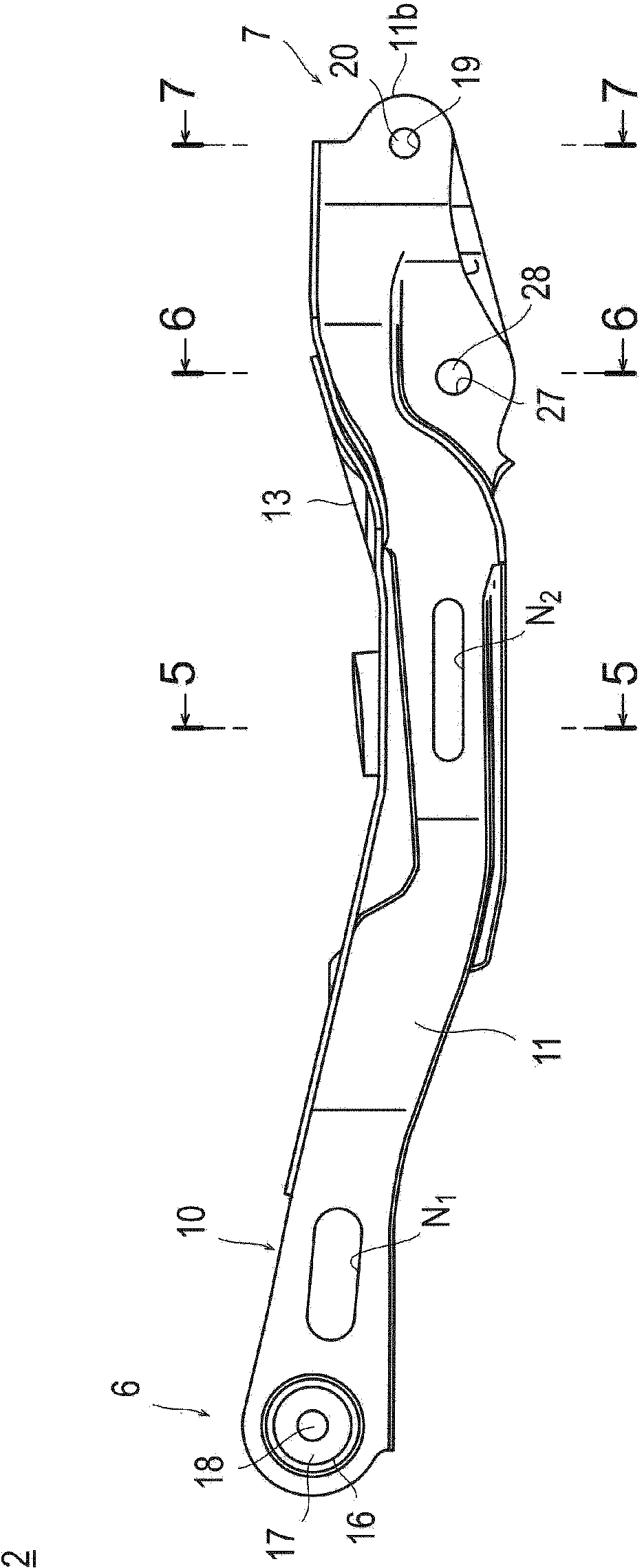

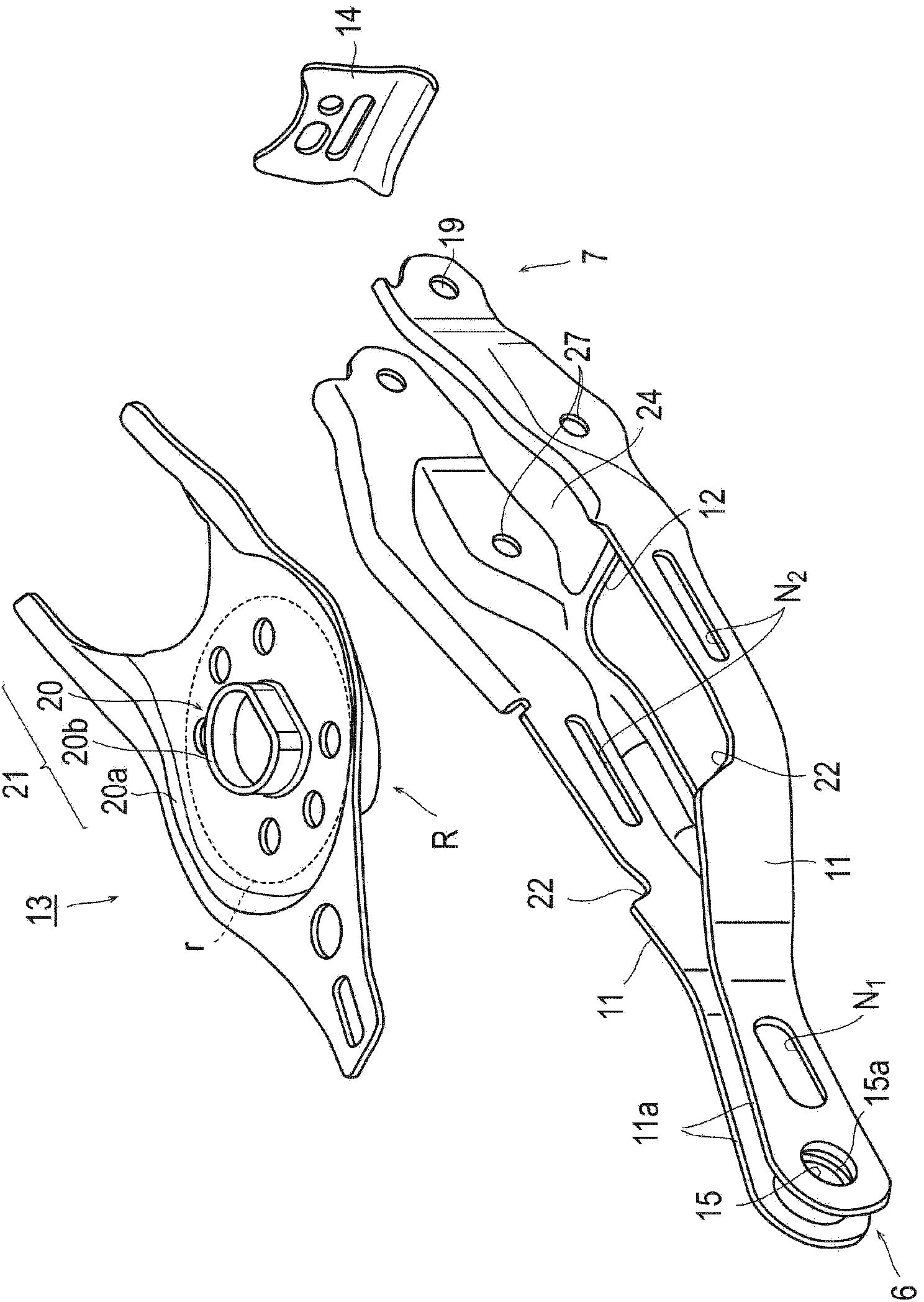

[0031] Such as figure 1 , 2 As shown, the lower arm 2 has: a long arm body 10; a spring support member 13, which is arranged on the upper part of the arm body 10, and supports the suspension coil spring 8; a connecting part 6 and a connecting part 7, which are arranged on the arm body 10 The two ends of the shaft are connected to the side A of the shaft or the side B of the car body.

[0032] Such as figure 2 , 3 As shown, the arm body 10 is generally open upward and has a U-shaped cross section, and has a pair of facing side plates 11 and a bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com