Permanent-magnet type electric rotating machine

A technology of rotating electrical machines and permanent magnets, which is applied to synchronous motors with stationary armatures and rotating magnets, magnetic circuit rotating parts, and the manufacture of motor generators, etc. It can solve the problem of large-scale permanent magnet rotating electrical machines and complex assembly And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Various embodiments will be described below with reference to the drawings. In addition, in the embodiments, the same reference numerals are assigned to common structures, and repeated descriptions are omitted. In addition, each figure is a schematic diagram for facilitating understanding of an embodiment, and the shape, size, ratio, etc. differ from an actual device, and design changes can be made as appropriate referring to the following description and prior art.

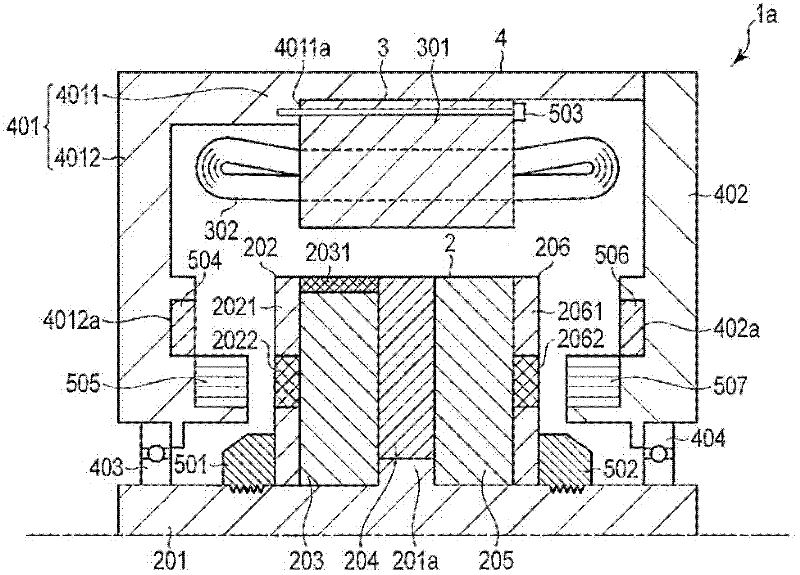

[0024] figure 1 It is an axial longitudinal cross-sectional view of the permanent magnet type rotating electrical machine 1a according to the first embodiment. The permanent magnet type rotating electrical machine 1 a includes a rotor 2 , a stator 3 , and a housing 4 . In the first embodiment, a direction perpendicular to the axial direction is called a radial direction.

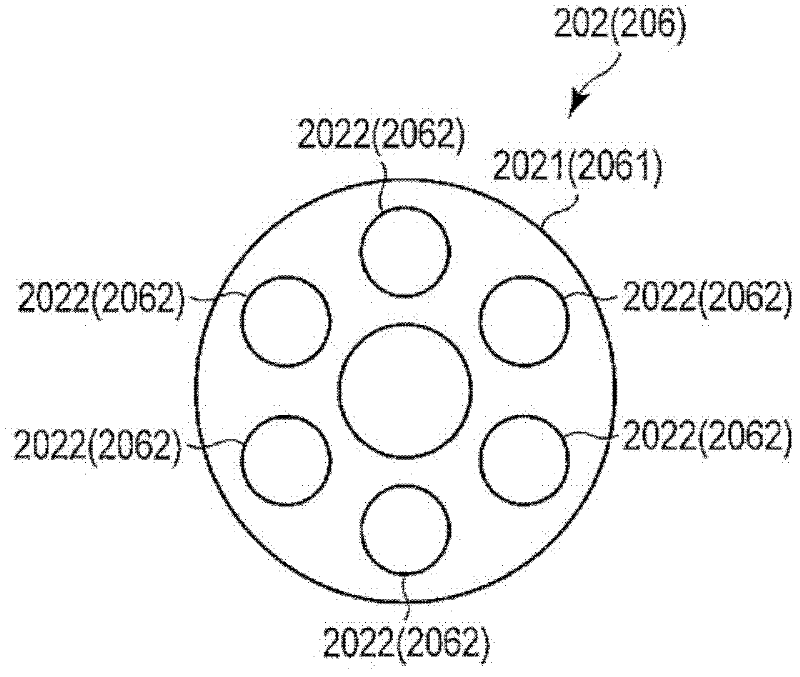

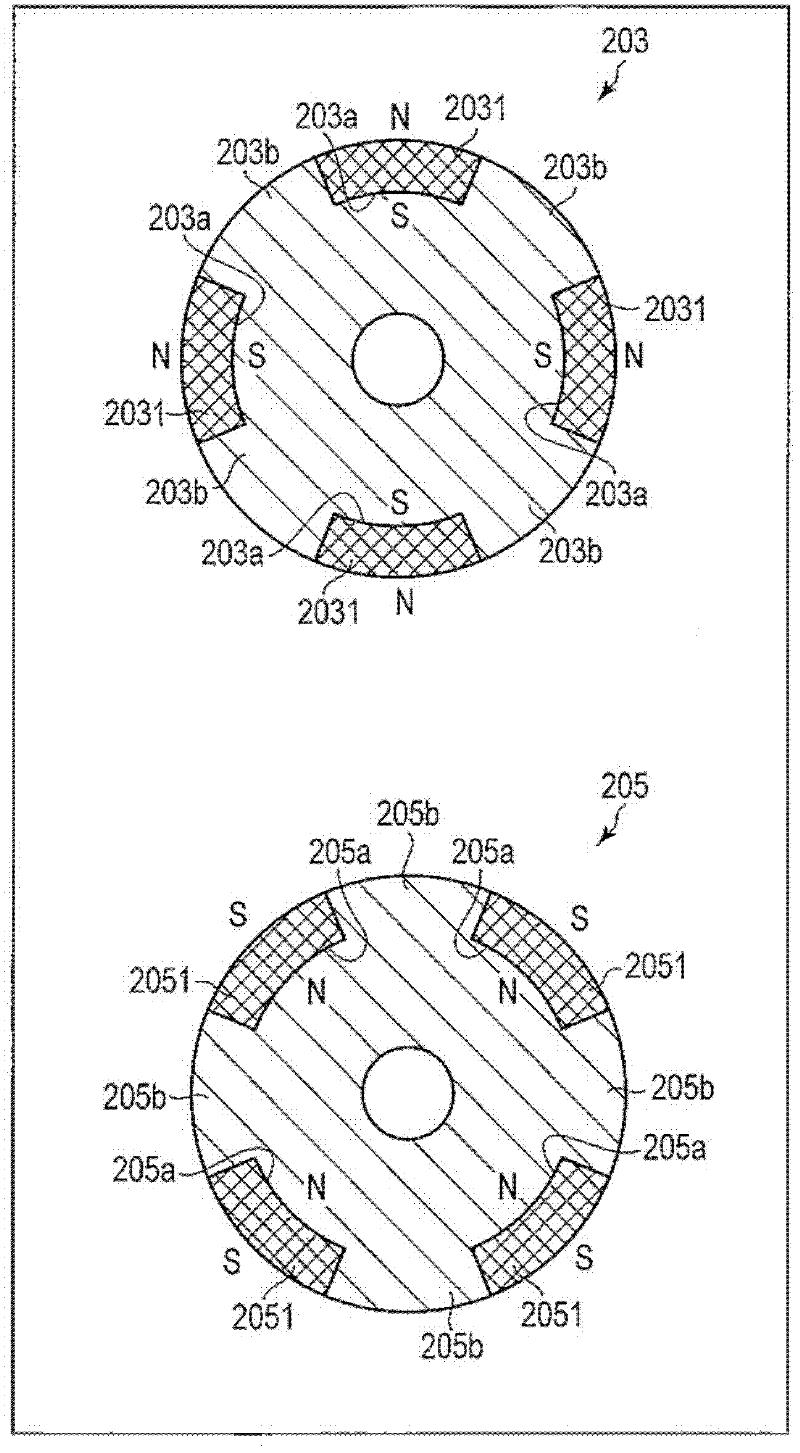

[0025] The rotor 2 includes a rotating shaft 201 , an end plate 202 , a rotor core 203 , a backing plate (Backing Plate) 204 , a rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com