Chain plate slot box stepping firecracker production machine

A step-by-step, production machine technology, applied in offensive equipment, pyrotechnics, weapon types, etc., can solve problems such as affecting the production efficiency of firecrackers, prone to accidents in semi-finished products, increasing manufacturing costs, etc., to reduce dust flying, and to achieve simple and accurate positioning. , The effect of not easy to miss the installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

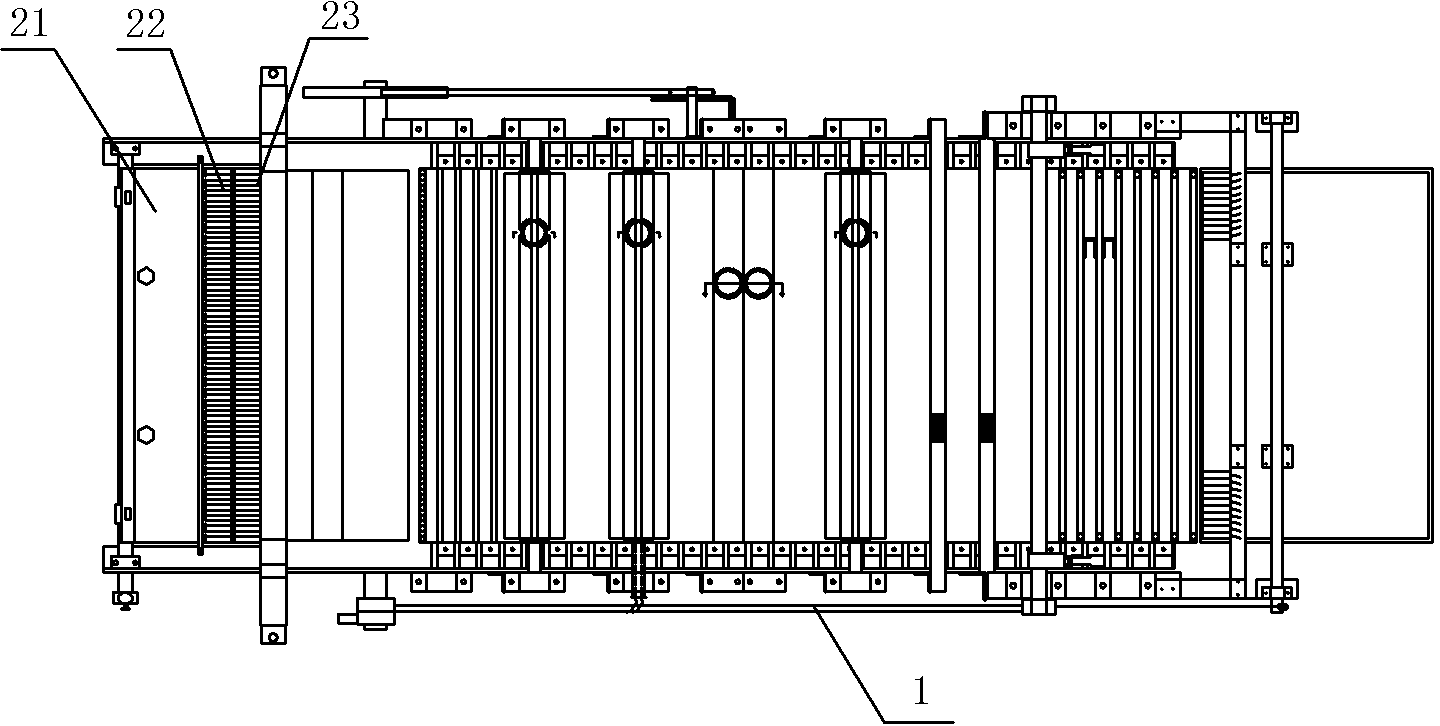

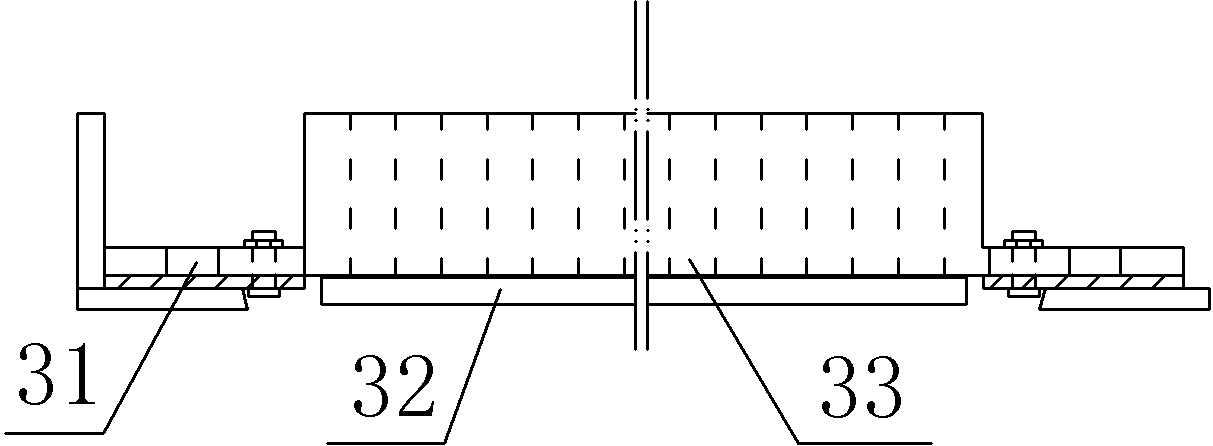

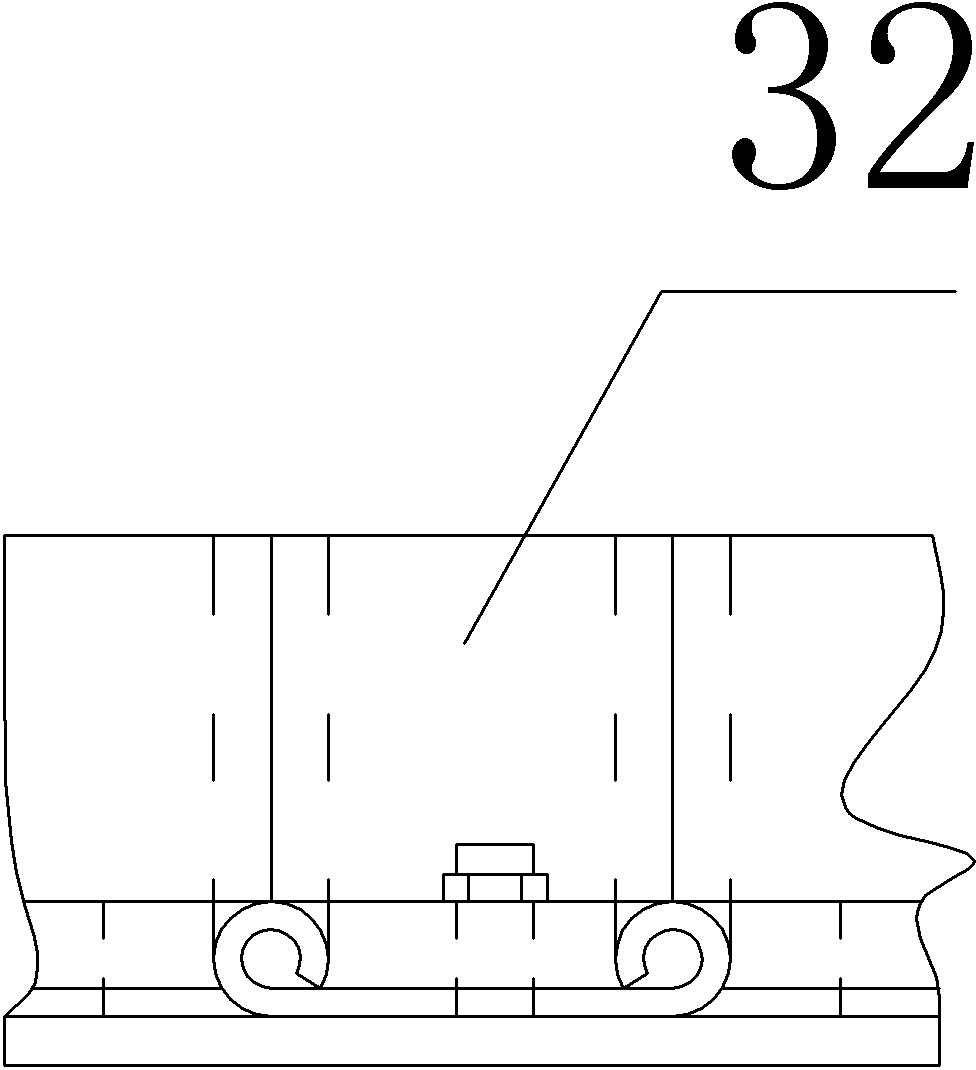

[0032] Such as figure 1 with figure 2 As shown, a chain plate tank box stepping firecracker production machine of the present invention includes a frame 1, a feeding device, a transmission device, a charging device and a cam, and the feeding device and the charging device are located above the transmission device.

[0033]The feeding device comprises a firecracker tube hopper 21, a display trough 22, a supplementary material hopper 23, a feeding channel 24, a first push plate 25 and a second push plate 26, and 100 firecracker tubes are placed in each row in the firecracker tube hopper 21, The first push pedal 25 and the second push pedal 26 can slide back and forth in both directions along the horizontal direction. The first push pedal 25, the thickness of the first push pedal 25 is less than the outer diameter of the firecracker tube, and the front side is a display groove plate 22, and the front and rear sides of the firecracker tube hopper 21 are provided with holes that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com