Ferrofluid optical current sensor with horizontal bias device and method

A ferrofluid, bias device technology, applied in the direction of measurement device, measurement of current/voltage, measurement of electrical variables, etc., can solve the problems of long response time, long relaxation time, low sensitivity and accuracy of non-constant current, etc. Achieve the effect of shortening response time, enhancing sensitivity, and optimizing dynamic characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, but not for limiting the protection scope of the present invention.

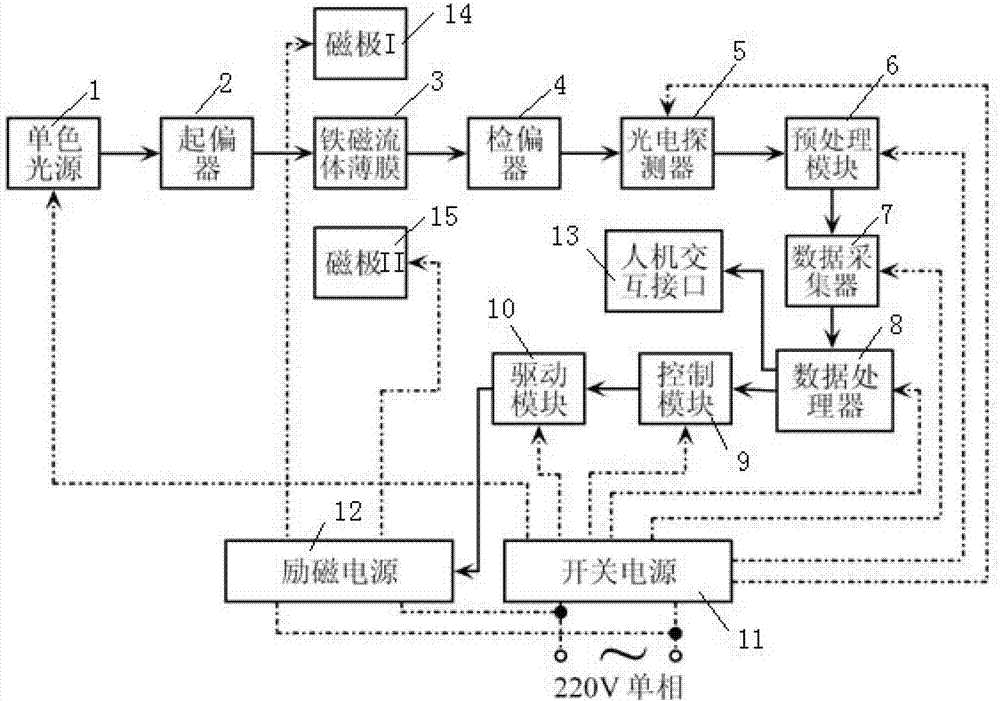

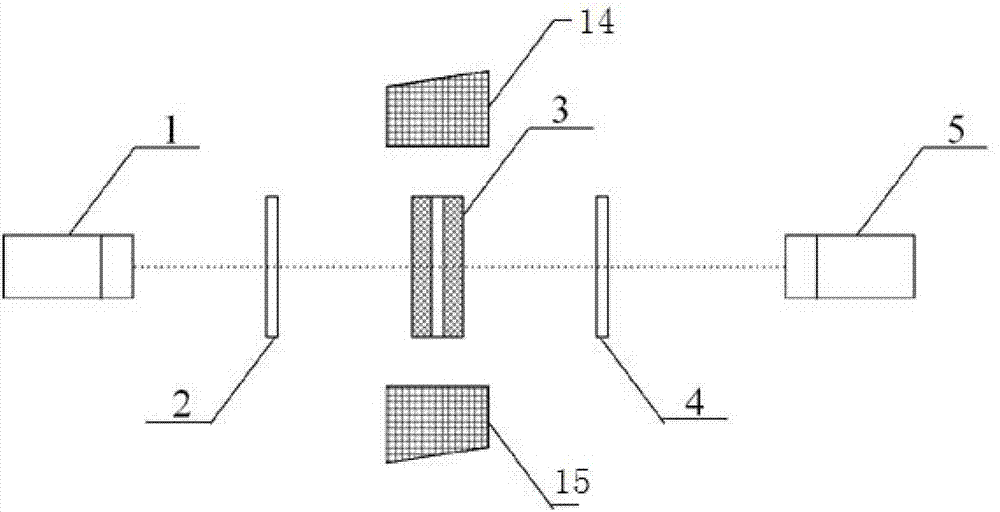

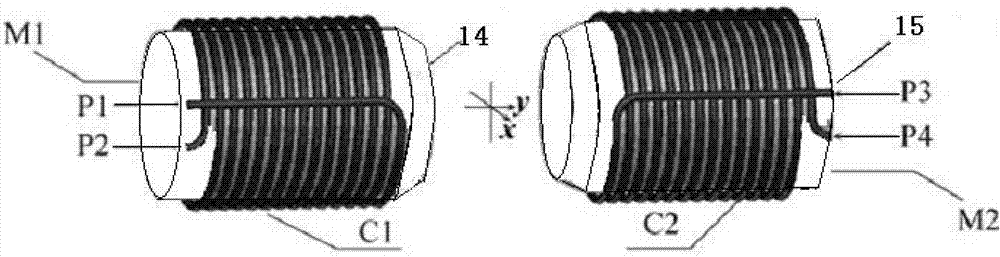

[0033] Such as figure 1 and figure 2 As shown, the ferrofluid optical current sensing device with a lateral bias device of the present invention includes a monochromatic light source 1, a polarizer 2, a ferrofluid thin film 3, an analyzer 4, a photodetector 5, Preprocessing module 6, data collector 7, data processor 8, control module 9, drive module 10, switching power supply 11, excitation power supply 12, man-machine interaction interface 13, magnetic pole I14 and magnetic pole II15;

[0034] The surface of the ferrofluid film 3 is kept perpendicular to the magnetic field generated by the current to be measured or the direction of the magnetic field to be measured...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com