Fixing device for placards

A technology for fixing devices and placards, which is applied to display devices, markings, instruments, etc., can solve the problems of troublesome, unsightly, and enterprise expenses for construction workers, and achieve the effect of convenient disassembly, firm and beautiful fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

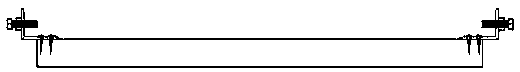

[0022] Step 1: Measure the width of the concrete and steel columns that need to be fixed on site, and make signs with appropriate widths. The steel and concrete columns on site generally have a width of 0.5-0.8 meters, which is just right for hanging signs.

[0023] The second step: intercept as Figure 5 A piece of L40*40*5 angle iron, in Figure 5 Open holes at the appropriate positions as shown, 4 φ3 self-tapping screw holes, 1 φ10.5 screw hole, align the center on the outside of the screw hole, and spot weld one Figure 5 M10 nuts shown, combined into Figure 6 Assemblies shown.

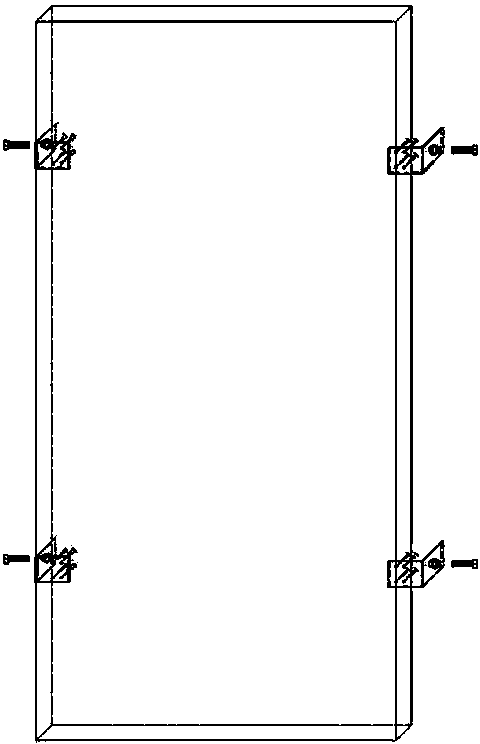

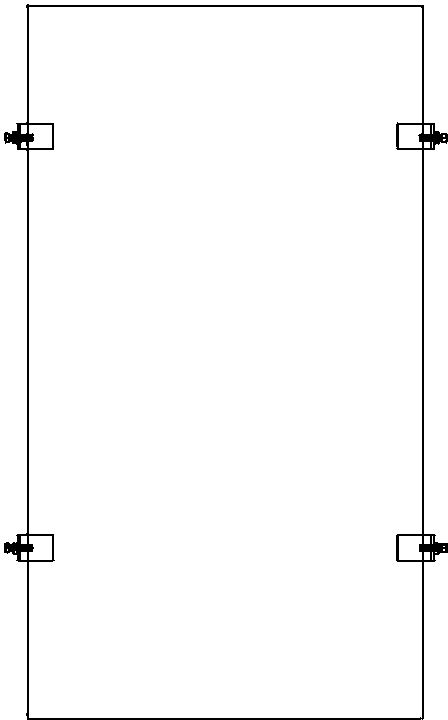

[0024] Step 3: Retrieve the placard, use Figure 7 Self-tapping handles shown Figure 6 Assemblies shown in sets of four, in figure 1 and figure 2 , image 3 , Figure 4 Just tighten the four corners as shown.

[0025] Step 4: Take the placard to the scene, choose an appropriate height, place the placard, and use Figure 7 Adjust the stress of the bolts shown as jacking wires, so that ...

Embodiment 2

[0031] The first step: same as embodiment 1;

[0032] The second step: intercept as Figure 5 A piece of L40*40*5 angle iron, in Figure 5 Holes are drilled at the appropriate positions as shown, 4 holes for φ3 self-tapping screws and 1 hole for φ10.5 screws.

[0033] The 3rd step: identical with embodiment 1;

[0034] Step 4: Take the placard to the site, choose an appropriate height, and place the placard; if the unit does not have welding conditions, install it in the order of bolts, angle irons, and nuts. The nuts are on the inside of the angle irons, and hold the nuts with a thin wrench Without turning, another wrench turns the bolt to make a fixed installation. Adjust its force so that the placard is fixed on the edge of the concrete column and steel column, and the fixing effect can also be achieved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com