Control circuit for cookware material judgment and method thereof

A control method and control circuit technology, applied in the direction of induction heating control, induction heating, induction heating device, etc., can solve the problems of inability to re-judgment, misjudgment, current difference affected by voltage, etc., and achieve anti-electromagnetic interference ability Strong, low-cost, reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the embodiments and accompanying drawings.

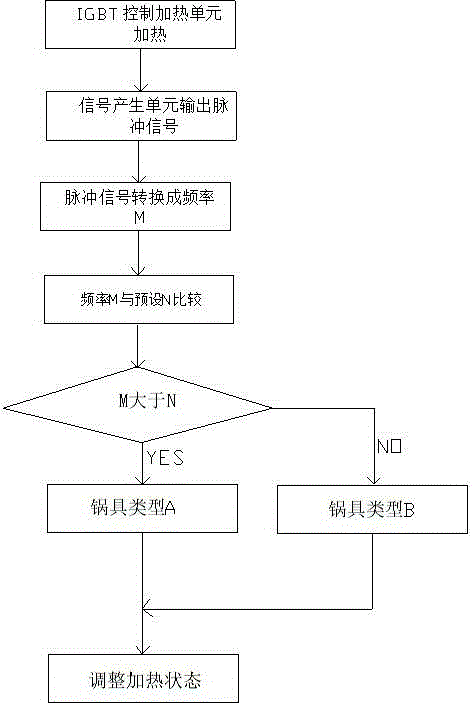

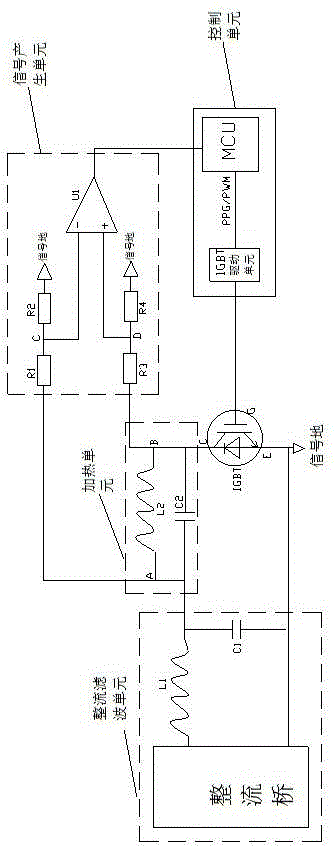

[0026] In this embodiment, the induction cooker is taken as an example, as figure 1 As shown, the control method for judging the pot material of the electromagnetic oven of the present invention comprises the following steps:

[0027] (1) When the induction cooker is working, the control unit controls the IGBT to heat the heating unit;

[0028] (2) The signal generation unit outputs a pulse signal to the MCU of the control unit according to the switching state of the IGBT;

[0029] (3) MCU records the input pulse signal and converts the pulse signal into frequency M;

[0030] (4) Compare the frequency M with the preset frequency threshold N. When the frequency M is greater than the preset frequency threshold N, it is judged that the pot type is A; if the frequency M is less than or equal to the preset frequency threshold N, the pot type is judged f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com