Method and apparatus for controlling variable valve system

A variable, valve timing technology, applied in the direction of valve device, electrical control, engine control, etc., can solve the problems of deterioration of combustion state of internal combustion engine, increase of exhaust emission, unsuitable characteristics of engine valve and valve, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

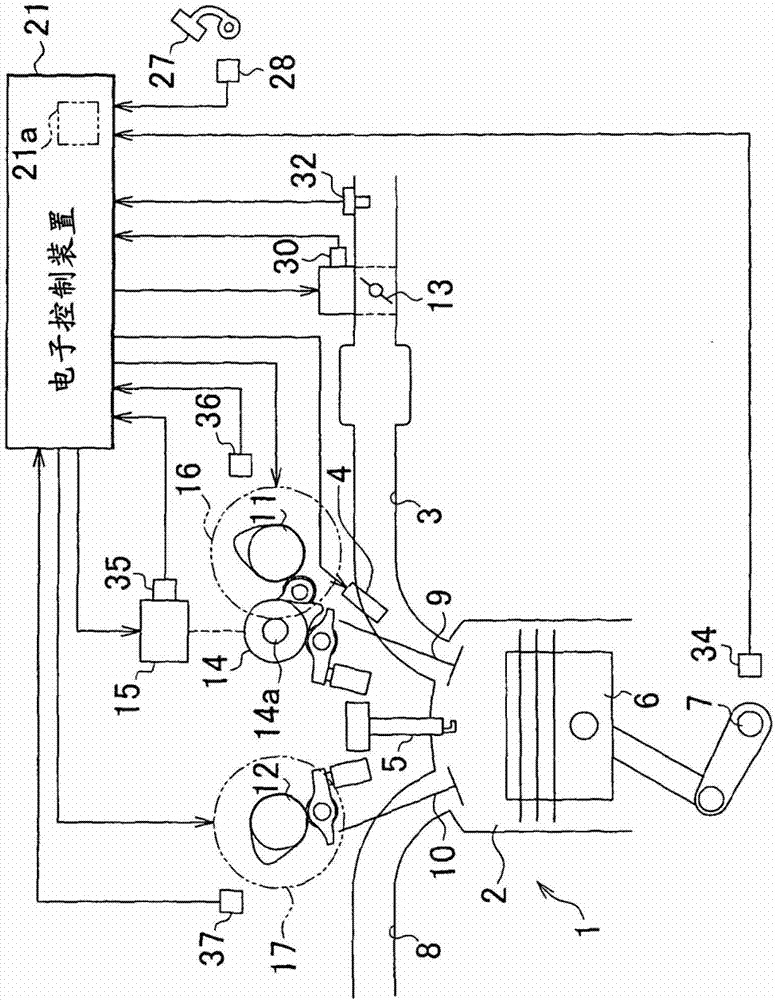

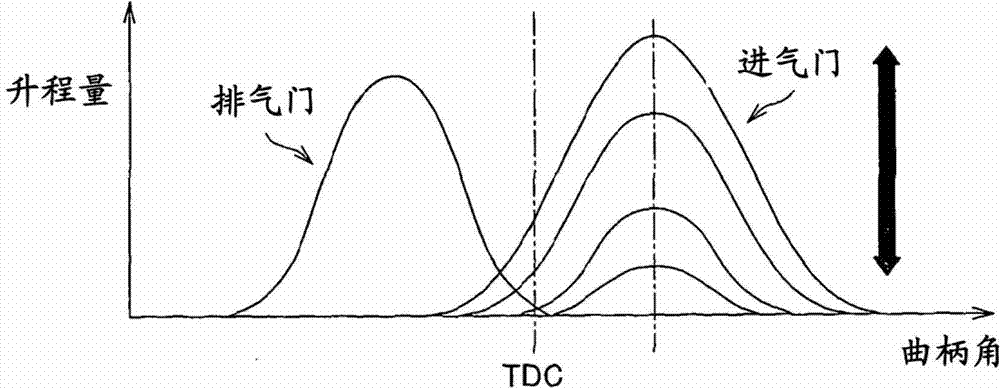

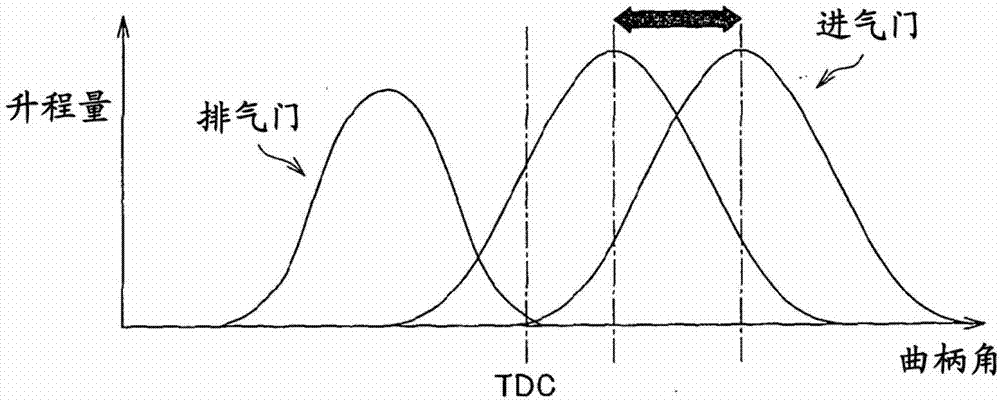

[0038] The following will refer to Figures 1 to 6 A first specific embodiment of a variable valve timing device for changing the valve characteristics of an engine valve such as an intake valve and an exhaust valve provided in an automobile engine according to the present invention will be described.

[0039] exist figure 1 In the engine 1 shown, a throttle valve 13 is arranged to be able to open and close in an intake passage 3 connected to a combustion chamber 2 of the engine 1 . Air is drawn into the cylinders via intake passage 3 , and fuel injected from fuel injection valve 4 is supplied to the cylinders via intake passage 3 . When the spark plug 5 ignites an air-fuel mixture formed of air and fuel, the air-fuel mixture burns, causing the piston 6 to reciprocate, and as a result, the crankshaft 7 serving as an output shaft of the engine 1 rotates. After being burned in the cylinder, the air-fuel mixture is discharged from the cylinder to the exhaust passage 8 as exhaus...

no. 2 example

[0085] Next, based on Figure 7 and 8 A second embodiment of the present invention will be described. In this embodiment, initialization processing with full stroke driving is always performed regardless of the presence or absence of an abnormality history, and the driving speed of the actuator 15 during the initialization processing is changed in accordance with the presence or absence of an abnormality history.

[0086] Figure 7 is a flowchart showing an initialization processing routine according to this embodiment. S301 to S304 of this initialization processing routine are equivalent to the initialization processing according to the first embodiment ( Figure 5 ) of S101 to S104. Therefore, when the abnormality history is stored in the RAM 21a of the electronic control device 21 (S301: YES), if it is judged in S302 that the execution condition is satisfied, the usual initialization processing (corresponding to the first initialization processing of the first embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com