Self-unloading container

A container and self-unloading technology, used in packaging, transportation and packaging, containers, etc., can solve problems such as power consumption, safety accidents, and self-weight of rubber-wheeled vehicles, reducing unloading operation time, reducing labor intensity, and improving safety. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in combination with specific embodiments.

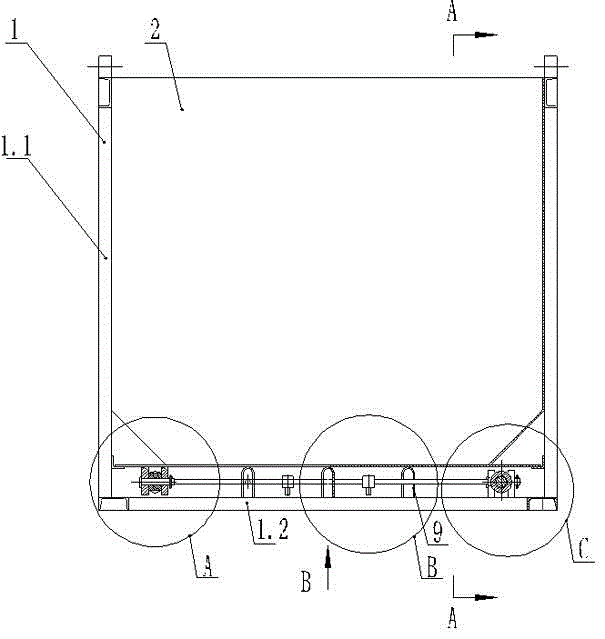

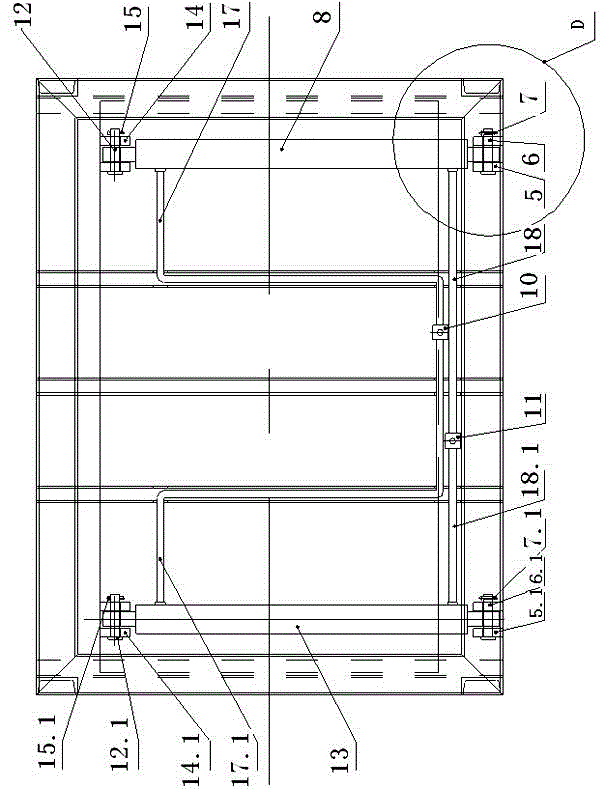

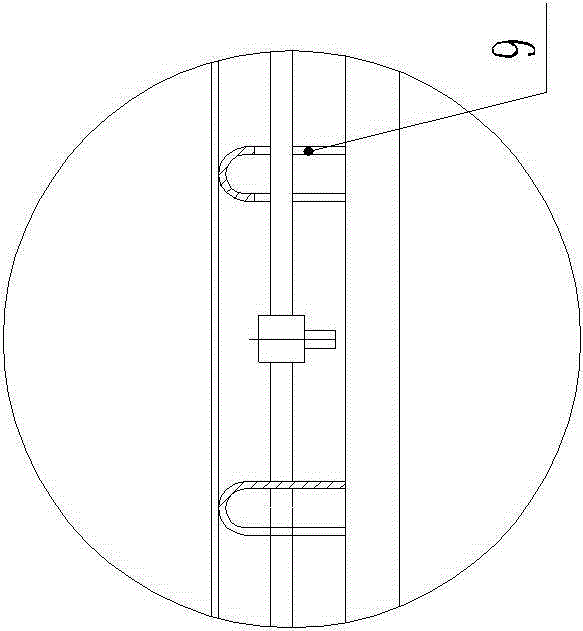

[0024] As shown in Figures 1, 2, and 3, a self-unloading container includes a box body 2 with a tapered lower part and a frame 1 for supporting the box body 2. The bottom of the box body 2 is provided with a sliding floor 3. The frame 1 is composed of a vertical support frame 1.1 and a base frame 1.2. The vertical support frame 1.1 is provided with two support guide grooves 4 for supporting the sliding bottom plate 3. The sliding bottom plate 3 In the space between the bottom frame 1.2 and along the direction of the support guide groove 4, cylinder one 8 and cylinder two 13 are arranged, and the cylinder parts of the cylinder one 8 and cylinder two 13 are all hinged with the base frame 1.2, and the cylinder one The piston rods of 8 and cylinder two 13 are all hinged with sliding base plate 3.

[0025] Such as figure 1 , 2 , 5, the base frame 1.2 is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com