Electrospinning nanofiber membrane preparing device with heating function

A technology for electrospinning nanofibers and preparing devices, which is applied in fiber processing, textile and papermaking, and bundling of newly ejected filaments, etc. Uniformity, the effect of promoting uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

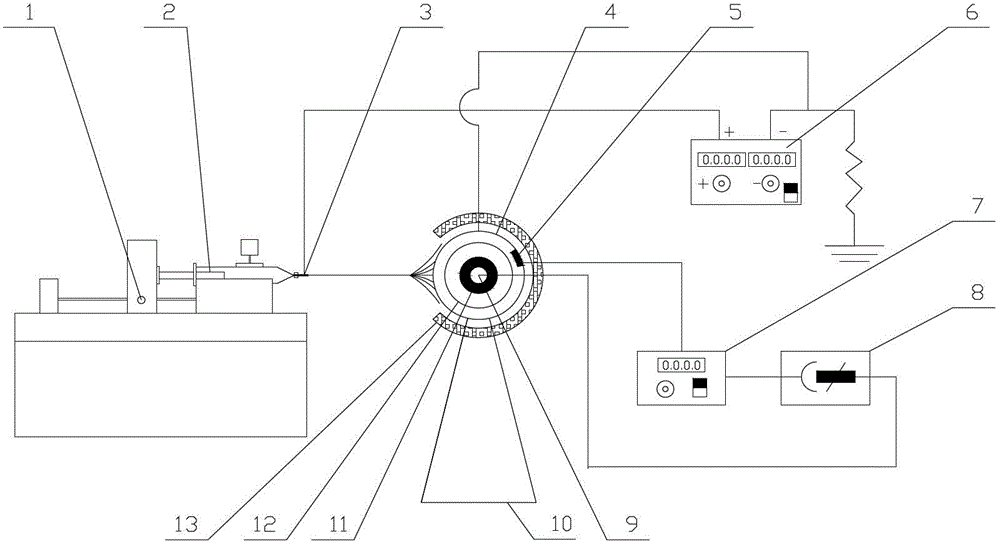

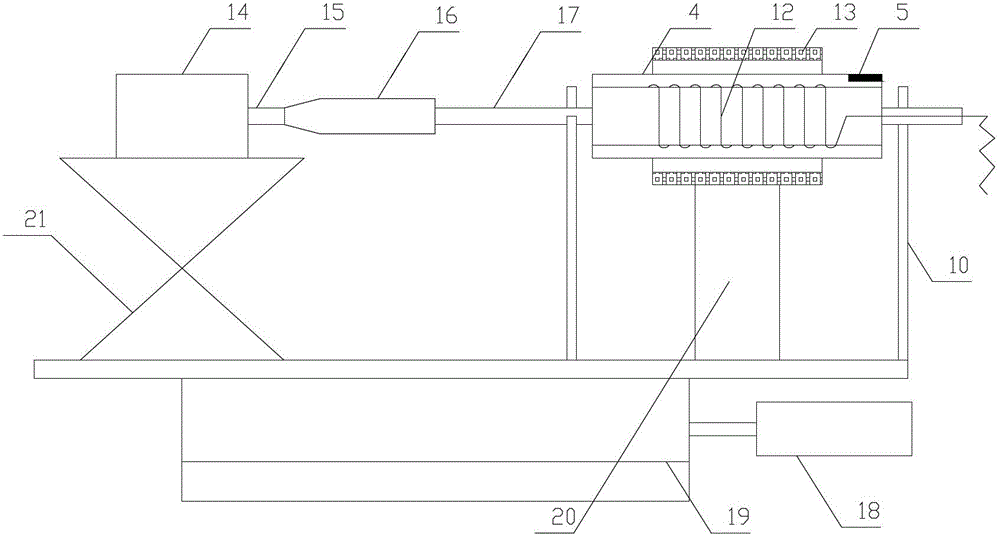

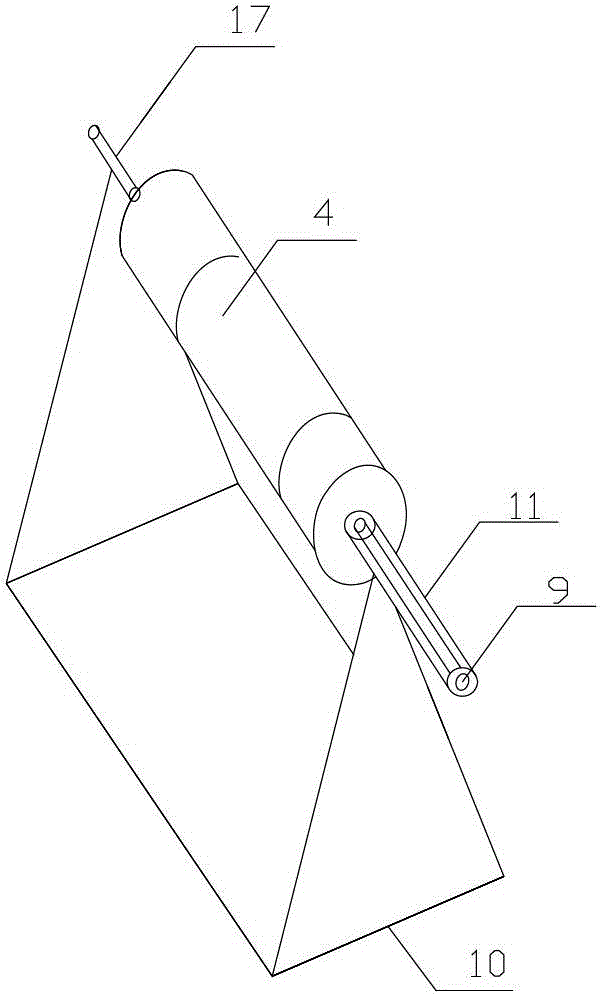

[0014] The embodiment of the present invention is provided with a liquid supply device 1, a nozzle 3, a drum 4, a temperature measuring element 5, a high voltage power supply 6, a numerically controlled temperature unit 7, a relay 8, a drum support frame 10, a drum shaft 11, an electric heating element 12, and an arc heat preservation Cover 13, rotating motor 14 (M1), insulating rod 16, roller shaft metal end 17, translation motor 18 (M2), horizontal moving device 19, heat preservation cover support frame 20 and motor support frame 21; the nozzle 3 is fixed on the supply On the liquid device 1, by adjusting the feeding speed of the liquid supply device 1, the supply speed of the solution in the electrospinning process can be controlled; an electric heating element 12 is arranged inside the drum 4 to control the temperature when collecting fibers; one end...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com