Co-plate flange air valve body and manufacturing method thereof

A technology of common plate flange and air valve, applied in the field of air valve and its production, can solve the problems affecting the adjustment performance of air valve, high production cost, poor overall strength, etc., and achieves low deformation, low labor cost and high processing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

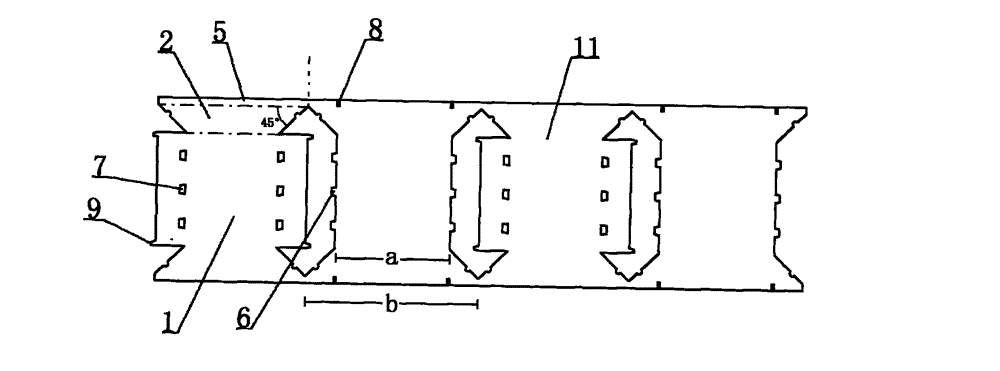

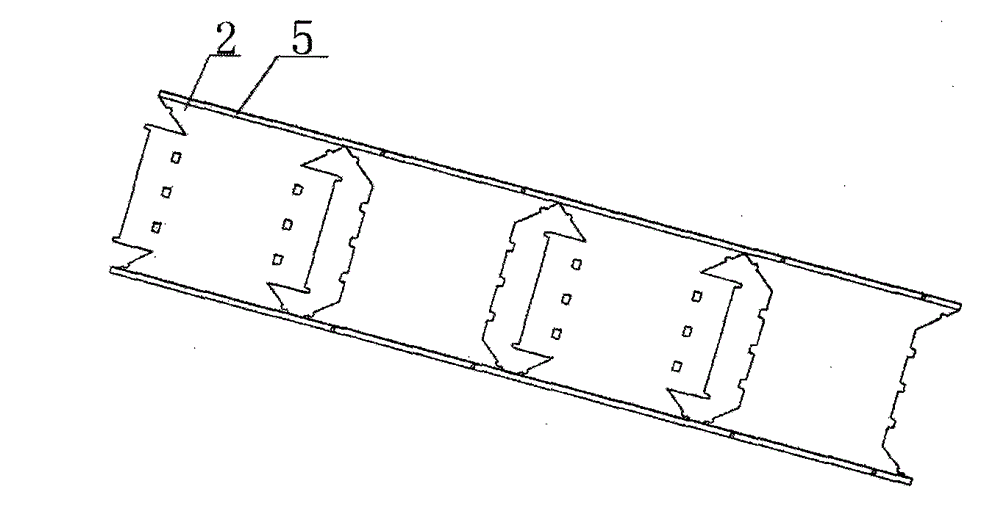

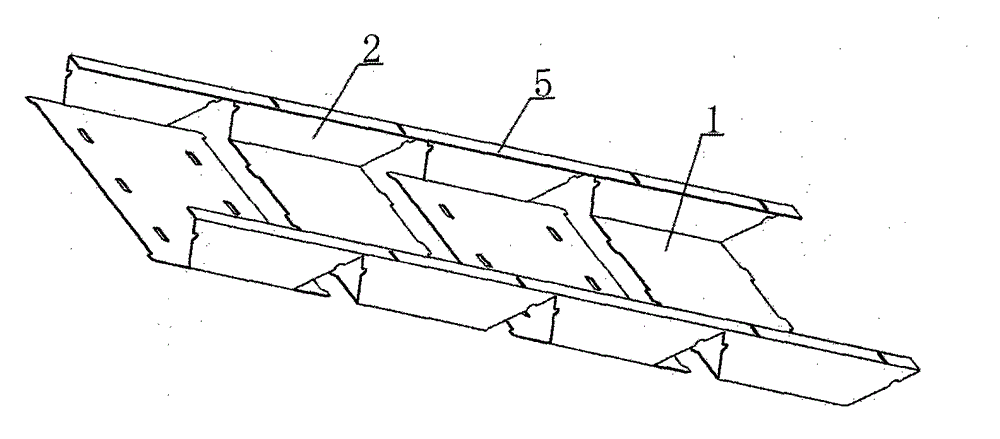

[0023] Such as figure 1 As shown, the galvanized sheet or white iron sheet is stamped or cut, and the excess part is removed, and the outer contour of the remaining sheet 11 is rectangular, forming four units distributed horizontally, and the four units pass through the upper and lower reserved folds 5 Connected as a whole; each unit includes a rectangular valve wall 1 and a trapezoidal flange 2 at the upper and lower ends. The four flanges 2 are of equal height, and the lower bottom angle is 45 degrees. The included angle of the lower bottom b (longer bottom) is provided with symmetrical half-holes on the adjacent flange 2; the separated units are a group with the same shape, and one group of valve walls 1 is formed by the flange 2 The upper bottom edge a is the width, and the buckle claws 6 are reserved on both sides, preferably 3 evenly distributed on each side, and three corresponding buckle holes 7 are opened on the valve wall 1 adjacent to it; the other group of valve wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com