Novel bagging device and method for large flat geotextile bag

A bagging device and bagging technology, which is applied to the new bagging device and bagging field of large flat geotechnical bags, can solve the problems of difficulty in moving the whole set of equipment, time-consuming and low efficiency of large geotechnical bags, and achieve huge economic benefits. Benefits and social benefits, high work efficiency, easy to move and carry effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

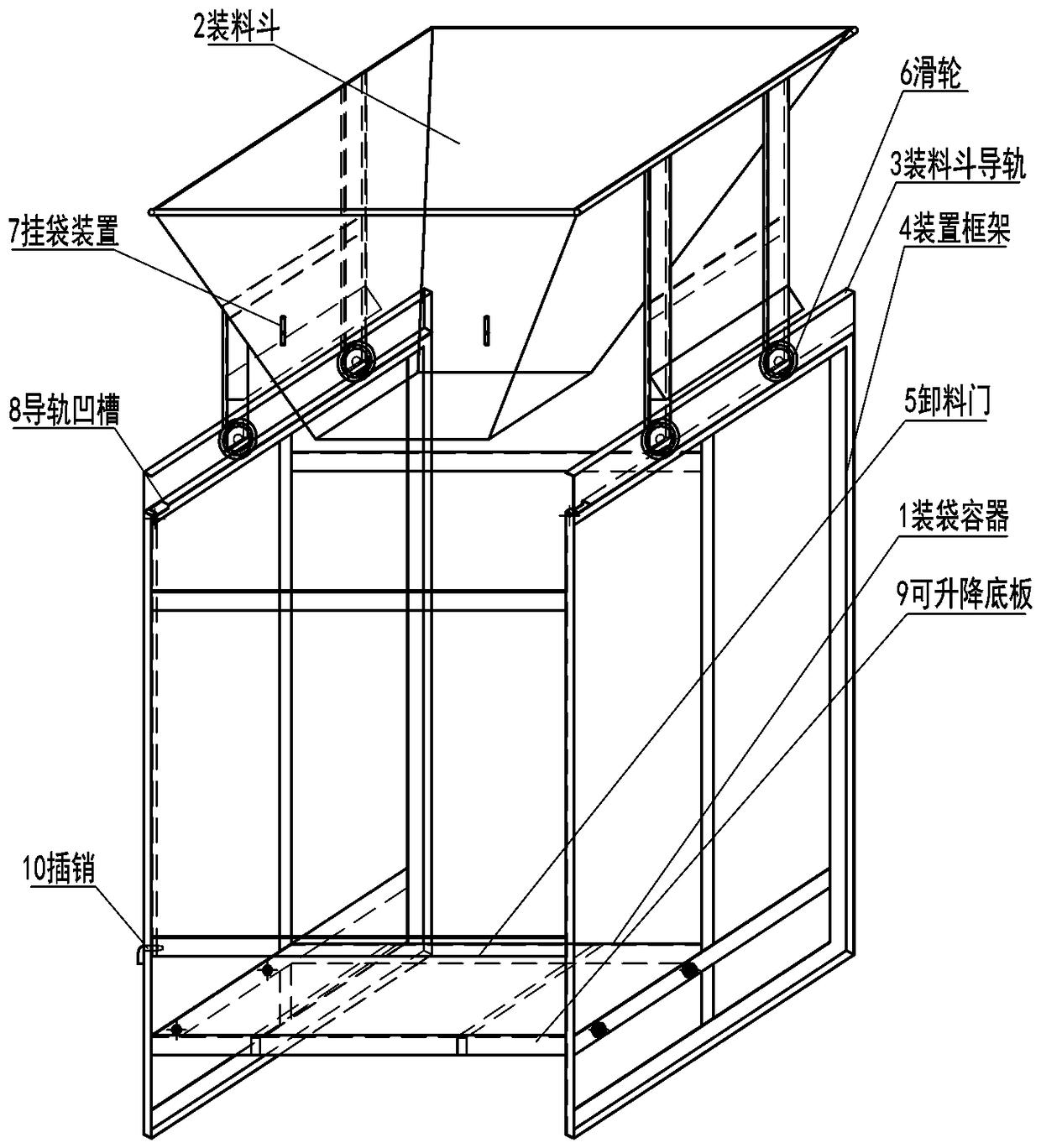

[0020] Refer to the attached figure 1 , specifically describe the device and method of the present invention.

[0021] A novel bagging device and bagging method for a large flat geotechnical bag. The bagging device is composed of a three-dimensional bagging container, a hopper, a hopper guide rail, and a device frame; the bagging methods realized by using this bagging device include: geotechnical bagging preparation, geotechnical bagging and geotechnical bagging unloading method.

[0022] The bagging container 1 is a left, right, rear and bottom four sides sealed, the top is open, and the front is a three-dimensional container composed of a movable door 5, forming a flat three-dimensional space that can place flat geotechnical bags. The size of this three-dimensional space can be determined according to the size of the geotechnical bag used.

[0023] The front movable door of the bagging container 1 is a so-called discharge door 5, and the top of the discharge door 5 has ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com