Coal mining roadway bracket holder car

A cable bracket and cable car technology, applied in the direction of pipes, hoses, etc., can solve the problems of cables and liquid pipes not being reliably fixed, cables being easy to jump and swinging left and right, and damage to the outer skin of cables and liquid pipes, etc., so as to achieve no potential safety hazard. , Conducive to standardized management, the effect of reducing coal mining costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

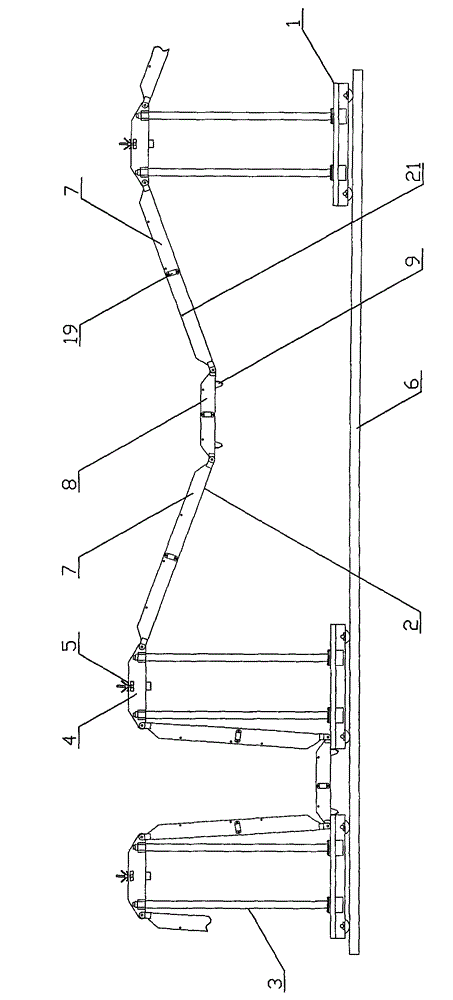

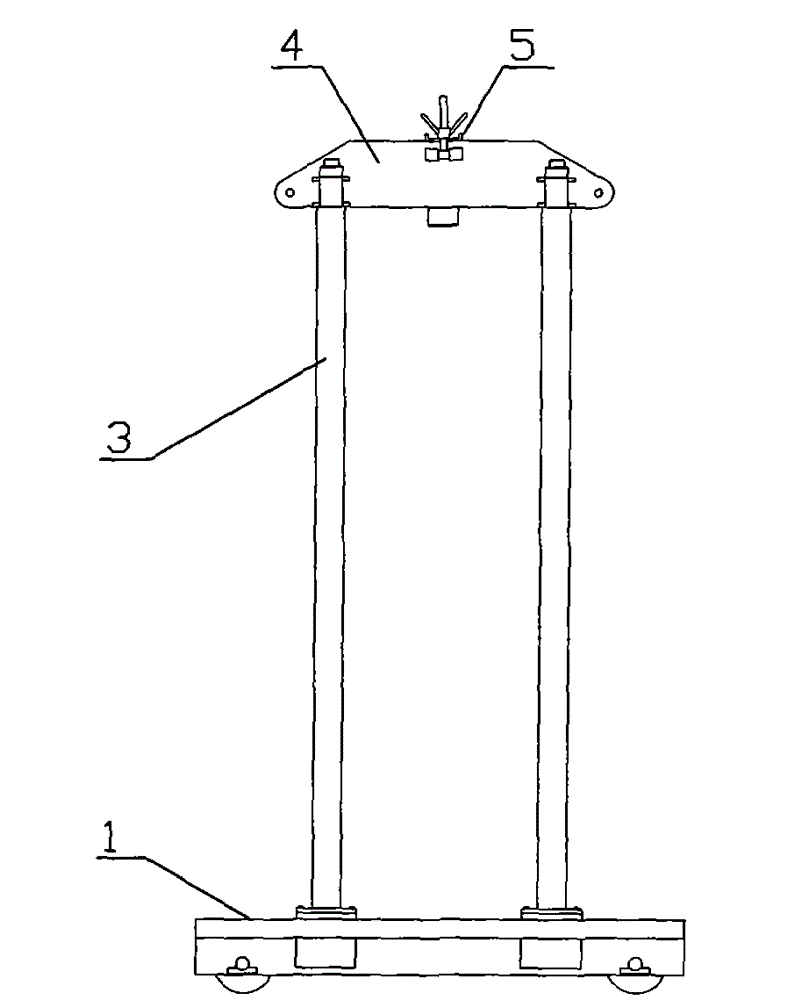

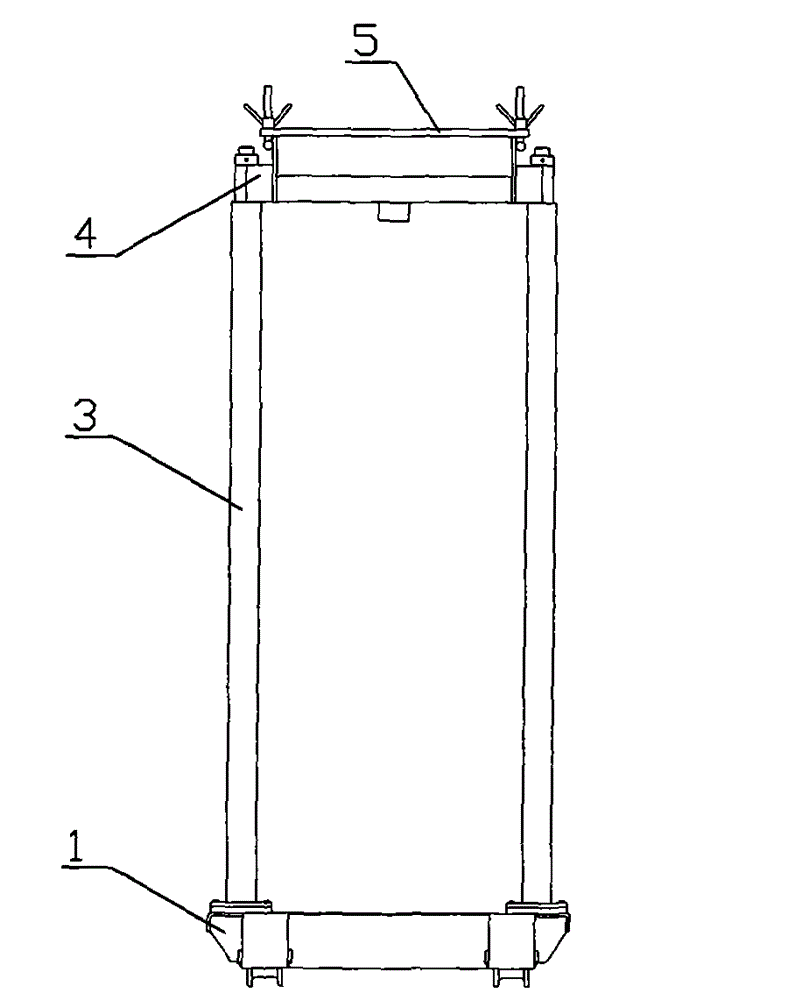

[0036] Embodiment 1: as Figure 1 to Figure 4 As shown, a coal mining roadway cable support car, which includes three cable cars 1, folding trough cable bridge frame 2, four columns 3, trough cable tray 4 and cable pressing plate 5; cable car 1 is placed on the roadway ground on the I-shaped steel track 6; each cable car 1 is provided with four columns 3 of equal length, a cable tray 4 is fixed on the top of the column 3, and a cable pressing plate 5 is fixed on the top of the cable tray 4; A folding trough cable bridge 2 is arranged between the two cable cars 1. The folding trough cable bridge 2 includes two main bridges 7 and a connecting bridge 8. The two ends of the connecting bridge 8 are respectively hinged with the inner ends of the two main bridges 7. , to form a connected unit cable bridge, and stoppers 9 are respectively fixed at the front and rear ends of the bottom of the connecting bridge 8 to limit the position when the adjacent cable car 1 shrinks to prevent the...

Embodiment 2

[0041] Embodiment 2: as Figure 5 to Figure 8As shown, a coal mining roadway cable support car, which includes three cable cars 1, folding trough cable bridge frame 2, four columns 3, trough cable tray 4 and cable pressing plate 5; cable car 1 is placed on the roadway ground On the I-shaped steel track 6; each cable car 1 is provided with four columns 3 of equal length; the column 3 is a lifting column 10, and the lifting column 10 includes a fixed column 11, a guide sleeve 12 and a lifting rod 13. The top of the column 11 is provided with a guide sleeve 12, and the lifting rod 13 is slidably set in the fixed column 11 and the guide sleeve 12. A positioning device 14 is provided on the lifting rod 13 to prevent the lifting rod 13 from sliding up and down, and is used for lifting and positioning the lifting rod 13. The top of the lifting rod 13 is fixedly connected with the cable tray 4; a cable pressing plate 5 is fixed on the top of the cable tray 4; a folding grooved cable b...

Embodiment 3

[0046] Embodiment 3: as Figure 9 to Figure 12 Shown, a kind of coal mining roadway cable support car as embodiment 2, it comprises three cable cars 1, folding trough cable tray 2, four columns 3, trough cable tray 4 and cable pressing plate 5; Column 3 is The liquid cylinder 22 and the top end of the liquid cylinder piston rod 23 are fixedly connected with the cable tray 4; other structures are the same as those in Embodiment 2.

[0047] How to use: When placing the cables on the cable car 1, the liquid cylinder 22 shrinks, and the cable tray 4 is placed in a low position, which is convenient for the placement of cables and liquid inlet pipes; arrange the cables neatly in thick lines and place them on the cable tray on the top of the cable car 1 4. In the foldable trough-shaped cable tray 2, use the cable plate 5 at the end of the cable tray 4, the cable fixing hole 21 and the cable fixing rod to press and fix the cables in the trough firmly; The liquid supply pipe is fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com