Active pressure-bearing positionable borehole stress gauge and its detection method

A drilling stress gauge, pressure-bearing technology, applied in hydraulic/pneumatic force measurement, force measurement, measurement devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

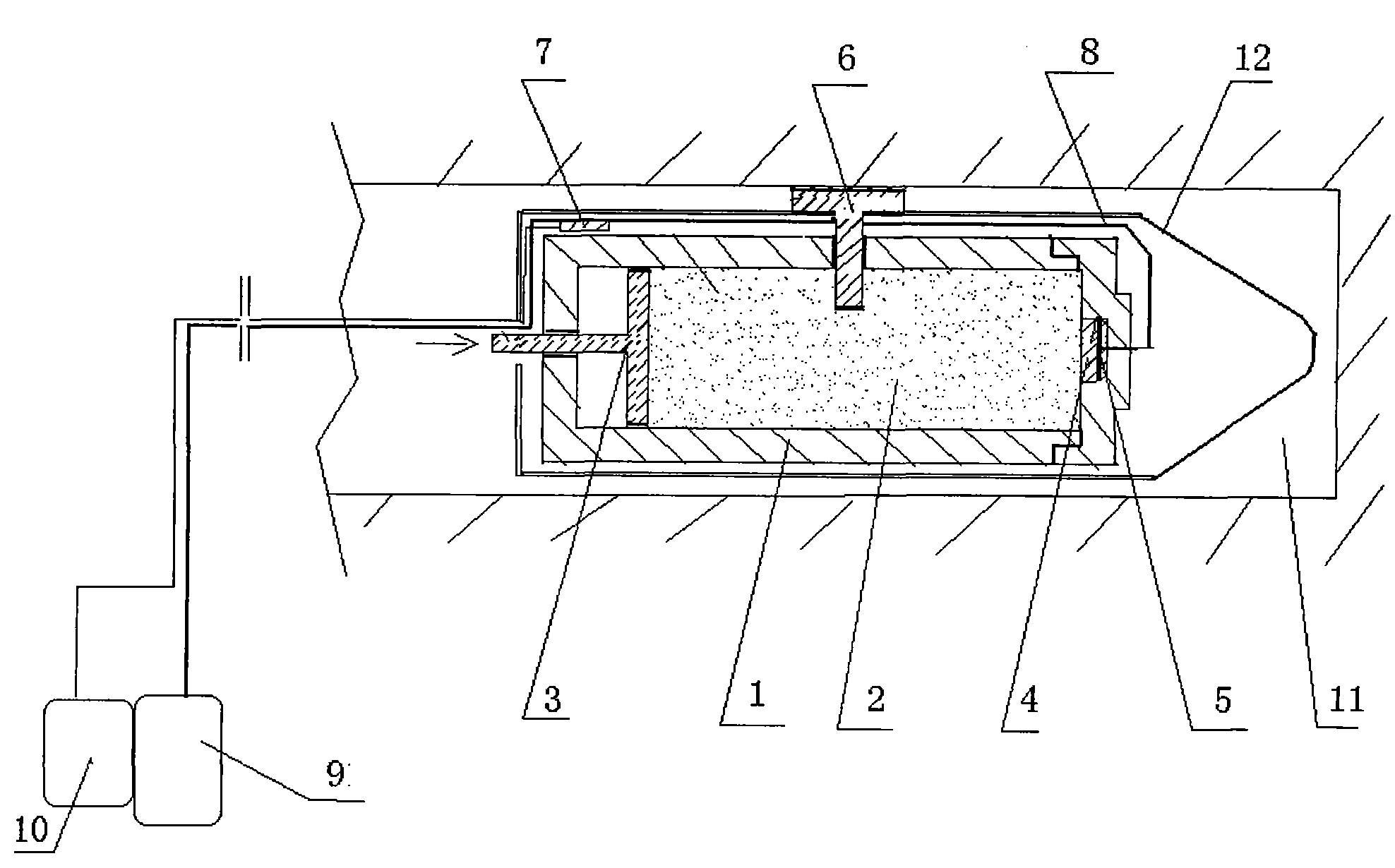

[0018] Such as figure 1 As shown, an active pressure-bearing type positionable borehole stress gauge includes a cylindrical shell 1 filled with paste grease 2, one end of the cylindrical shell 2 is provided with a piston 3, and the other end is provided with elastic Sensing body 4, elastic sensing body 4 is provided with strain gauge 5, one side of cylindrical housing 1 is provided with a rigid carrier 6, rigid carrier 6 extends into cylindrical housing 1, rigid carrier 6 and cylindrical housing 1 The contact part should be in sealed contact; it has an angle sensor 7 fixed on the cylindrical housing 1.

[0019] In order to protect the above-mentioned borehole stress gauge in use and smoothly push it into the deep part of the borehole, it also includes a housing 12 with a cone.

[0020] The method of use of the present invention is,

[0021] In the first step, first bind the active pressure-bearing positionable borehole stress gauge of the present invention to the pole, push the pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com