Fatigue damage estimating method and monitoring device under multi-axis random load

A fatigue damage and random load technology, applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc., can solve problems such as strength assessment and life prediction of major equipment that cannot meet the requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

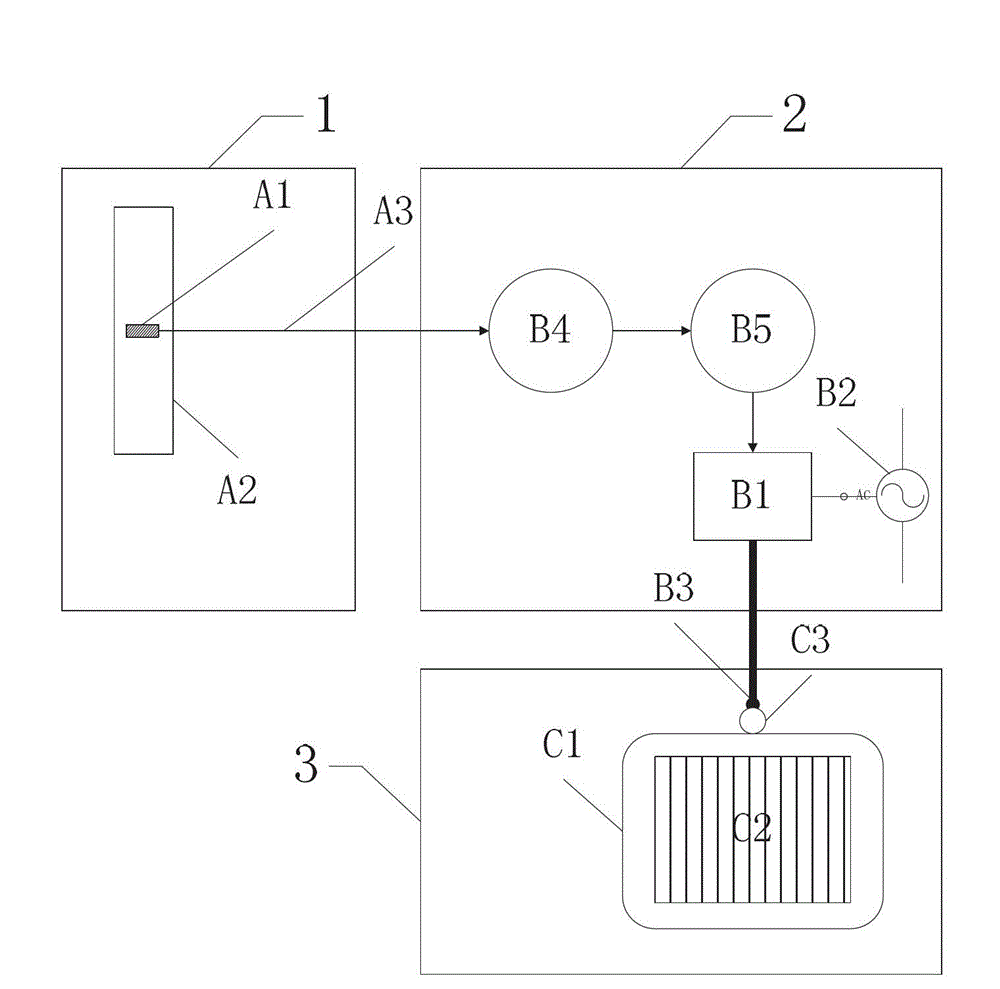

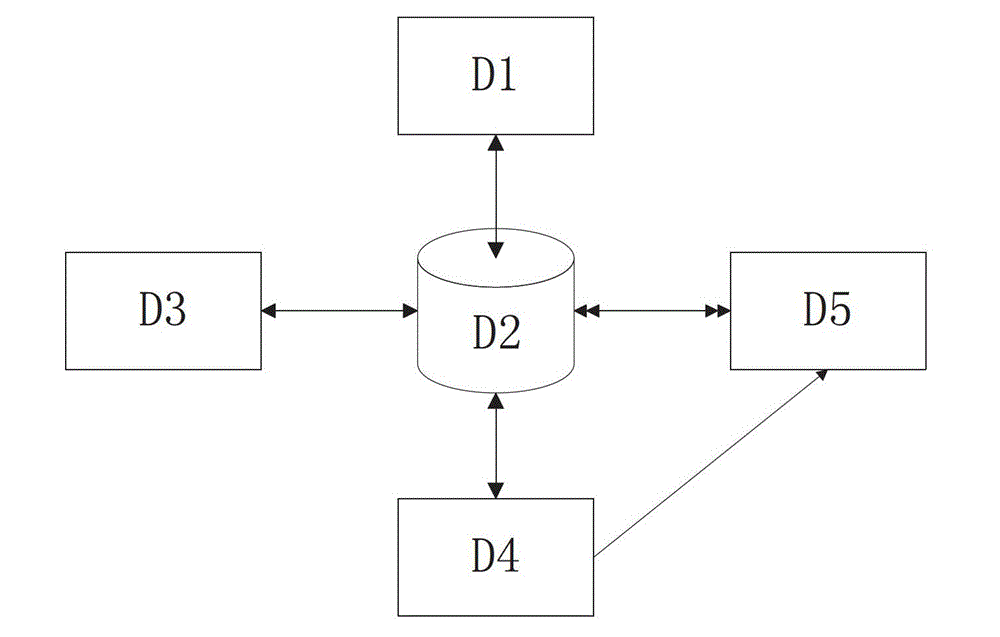

[0029] For the specific structure of this embodiment, see figure 1 , the device mainly includes a data acquisition system 1, a data processing system 2, and a data monitoring system 3. Data acquisition system 1 includes key mechanical parts A2, strain sensor A1, and data transmission line A3; data processing system 2 includes data acquisition card B1, AC power supply B2, USB transmission line B3, power amplifier B4, and A / D converter B5; data monitoring System 3 includes computer C1 and software monitoring system C2. Software monitoring system C2, specific structure to participate in figure 2 , including a user login module D1, a database D2, a real-time data display module D3, a fatigue damage calculation module D4, and a historical record storage and viewing module D5; among them, the strain sensor A1 is attached to the gap of the key mechanical parts A2, and through the data transmission line A3 Connect with the power amplifier B4, connect the power amplifier B4 with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com