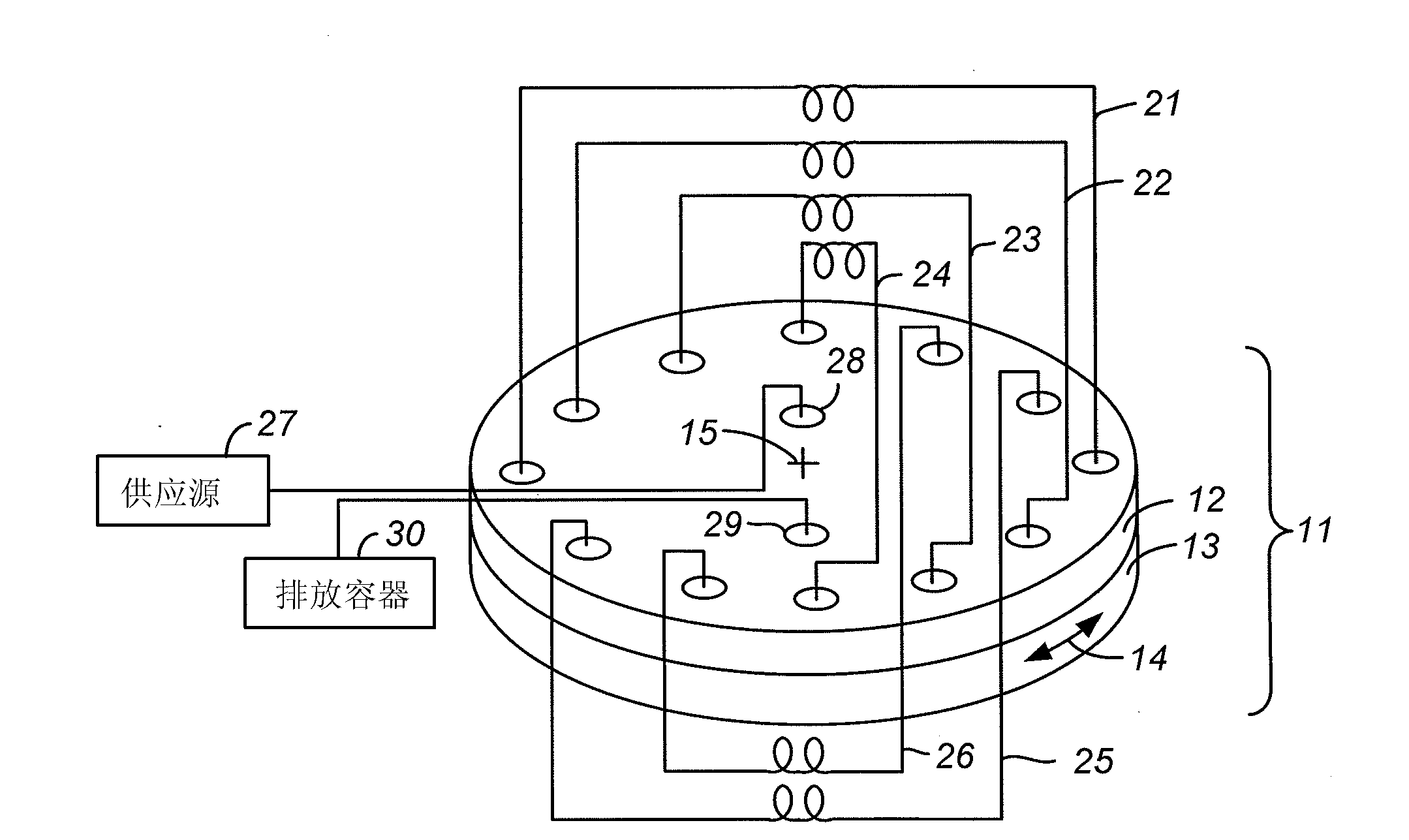

Rotary column selector valve

一种旋转阀、圆弧的技术,应用在多通阀、阀装置、仪器等方向,能够解决增大污染、增大使用者、设计复杂等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

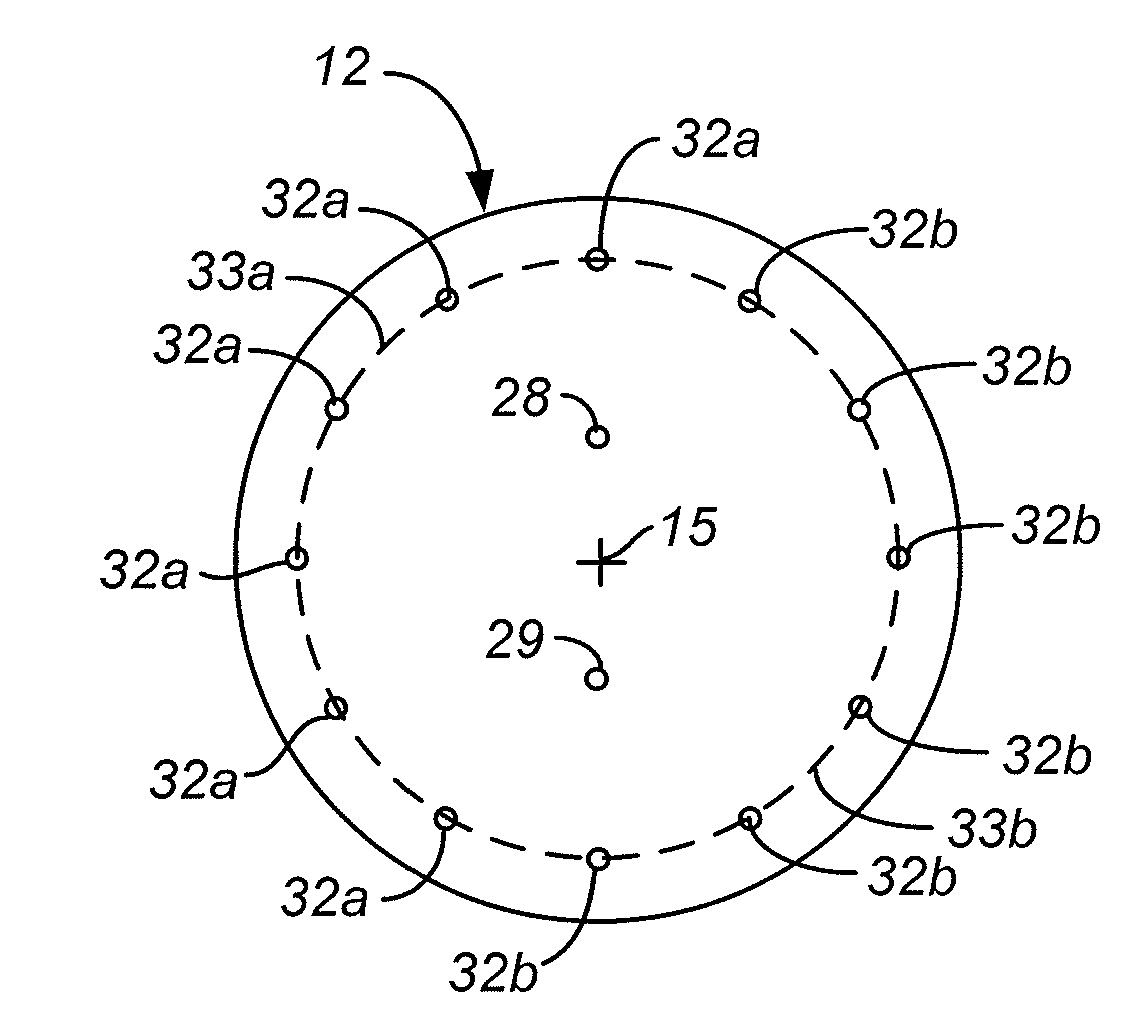

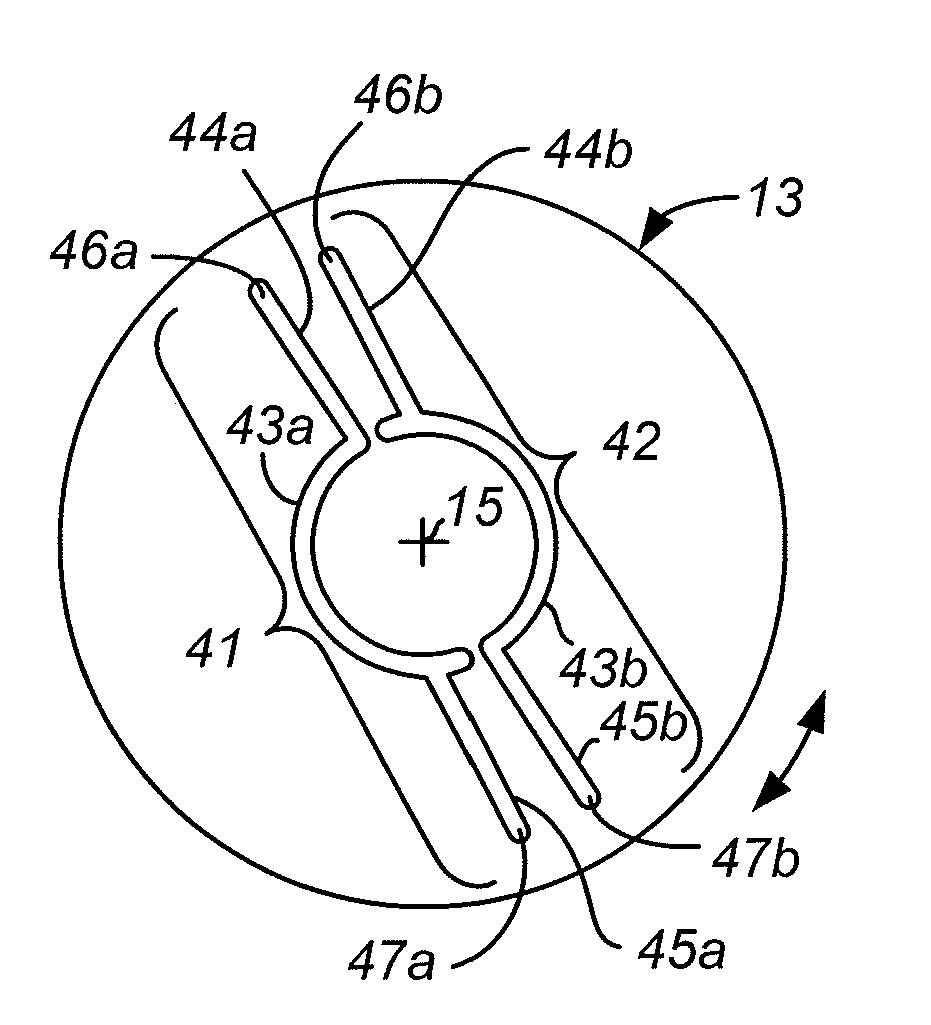

[0013] As noted above, the term "component" is used herein to denote the unit to which the rotary valve supplies fluid or from which it receives fluid. Many such cells are flow-through cells. Examples of such "components" are cylinders, loops, filters and detectors. The term "component port" is used herein to denote a port in a rotary valve that is connected to a component, in many cases, through a connecting tube. Component ports are used to supply fluid to and receive fluid from a component, and typically a component is connected to two component ports, one for supplying fluid to the component and the other for receiving fluid leaving the component.

[0014] The term "valve inlet port" is used herein to denote a port of a rotary valve designated to receive fluid from a fluid supply external to the valve and through which fluid enters the internal chamber of the valve for delivery to the component port. Likewise, the term "valve outlet port" is used herein to denote a port ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com