Descaling equipment for high temperature billet in hot extrusion process of seamless steel pipe

A technology of seamless steel pipe and descaling equipment, which is applied to metal extrusion cleaning equipment, metal processing equipment, metal extrusion and other directions, can solve the problems of time-consuming, cumbersome descaling equipment, etc., and achieves convenient use and simple structure. Practical and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

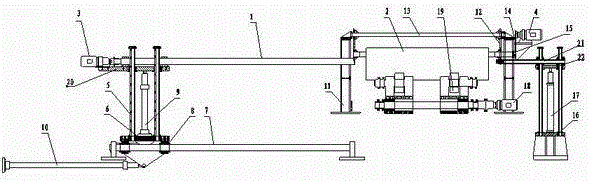

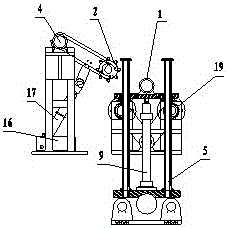

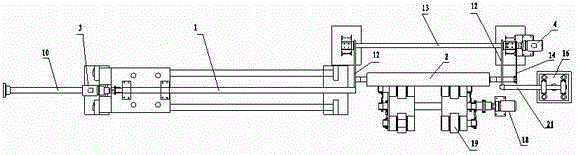

[0015] as attached Figure 1-Figure 3 In the illustrated embodiment, the present invention includes: a billet inner circle descaling mechanism and a billet outer circle descaling mechanism; the billet inner circle descaling mechanism is connected by an inner circle descaling drum 1 and an inner circle descaling reducer 3 is connected by a guide 20 is connected to the vertical shaft frame and the cylinder height adjustment hydraulic cylinder 9, and the bottom of the vertical shaft frame is connected to the hydraulic cylinder 10 for moving the cylinder left and right; , the outer circle descaling reducer 4 is installed and connected on the lifting stand 11, and the lifting stand 11 is equipped with a swing arm mechanism to connect respectively the outer circle descaling and shaking the cylinder 2 and the outer circle descaling and shaking the cylinder to adjust the hydraulic cylinder 17. The circular descaling cylinder 2 is also connected with the supporting wheel 19 equipped wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com