Color code type automatic positioning product detection device and method

An automatic positioning and positioning detection technology, applied in printing, printing machines, general parts of printing machinery, etc., can solve the problems of high implementation cost, complex system, missed detection, etc., to achieve a simple and flexible solution, adding additional processes and operations. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

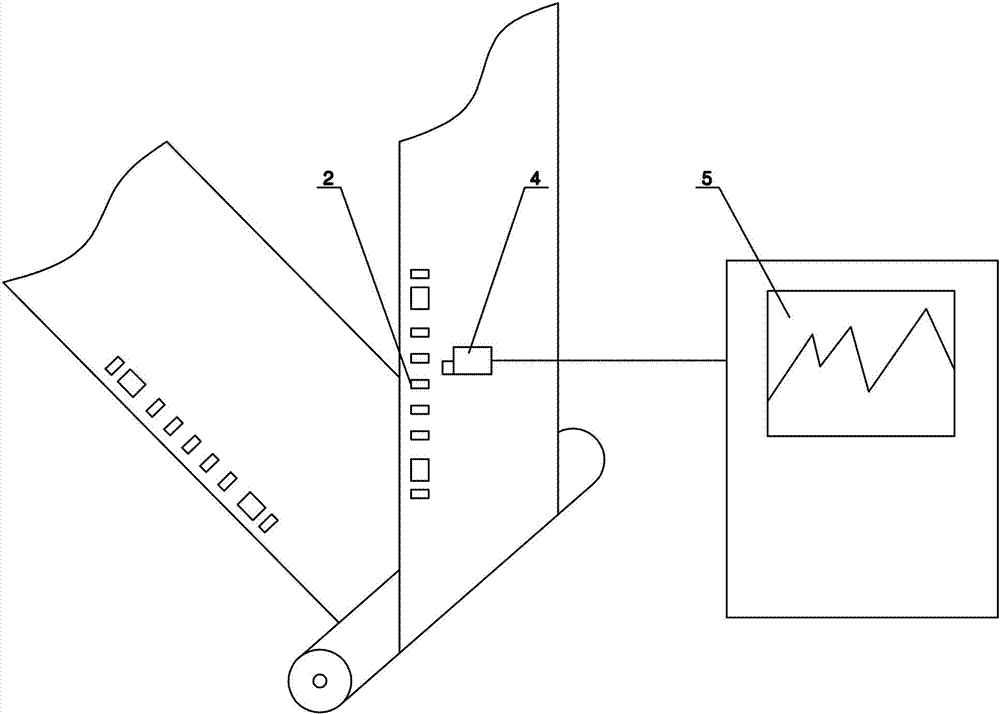

[0024] Such as Figure 1-3 Among them, a color-mark type automatic positioning and inspection device includes a computer system 5 for image comparison, a photoelectric scanning head 4 connected to the computer system 5, and a detection color mark 2 corresponding to the color used for overprinting is set on the printed matter. The photoelectric scanning head 4 described above is located at a position corresponding to the detection color mark 2 on the printed matter.

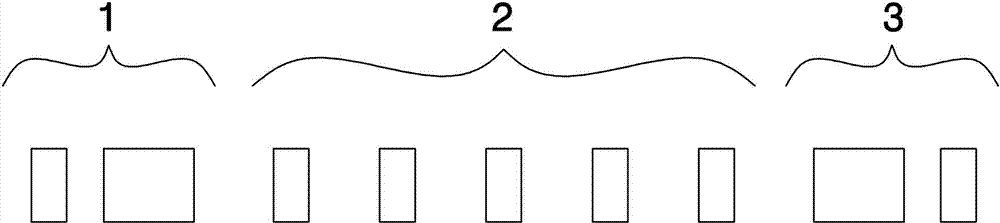

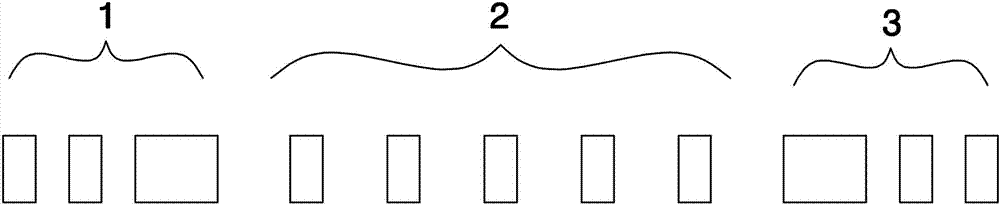

[0025] One or both ends of the detection color mark 2 are provided with positioning and detection synchronization marks used as comparison references. The optimized scheme is as figure 1 , 2 As shown in , both ends of the detection color mark 2 are provided with the first positioning detection synchronization mark 1 and the second positioning detection synchronization mark 3 as comparison references, so that the structure does not need to consider the detection direction of the printed matter.

[0026] The firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com