Protection system of full-functional belt conveyer

A technology of belt conveyor and belt, which is applied in the direction of conveyor objects, transportation and packaging, conveyor control devices, etc., can solve the problems of large resource occupation, unfavorable operation status of belt conveyor protection devices, and many protection devices, so as to reduce laying , Address setting is simple and convenient, reducing the effect of control wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

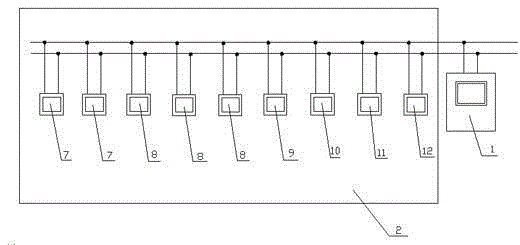

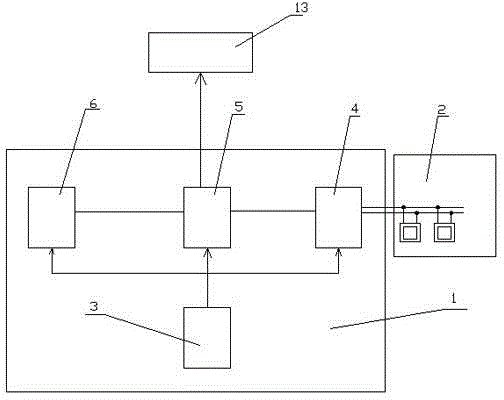

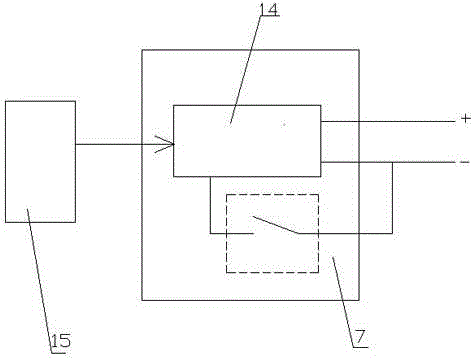

[0026] Such as figure 1 and 2 Shown: a full-featured tape conveyor protection system, which is composed of a head controller 1 and a tape protection device 2. The head controller 1 is set at the head position of the belt conveyor, and is composed of a switching power supply 3 and a bus interface. Composed of a converter 4, a PLC controller 5 and a touch screen 6; the tape protection device 2 includes a pull cord switch 7, a deviation switch 8, a stall switch 9, a blockage switch 10, a longitudinal tear switch 11 and a smoke temperature sensor 12, wherein the pull rope switch 7 is arranged on the same side of the belt conveyor edge, the deviation switch 8 is a limit sensor arranged on both sides of the belt conveyor, and the stall switch 9 is a speed sensor arranged on the driven shaft of the conveyor, and The blockage switch 10 is a material pressure sensor arranged on the chute of the belt conveyor, the vertical tear switch 11 is a touch sensor arranged in the middle of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com