Railway elevating and fixing device and railway bridge and culvert construction method adopting railway elevating and fixing device

A technology for fixing devices and railways. It is applied in the direction of erecting/assembling bridges, roads, bridges, etc. It can solve the problems of speed requirements and small overhead spans that cannot be met, and the fixing effect cannot meet the requirements of railways, etc., so as to achieve the convenience of erection and assembly, and the cost of hoisting and transportation Low, good safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

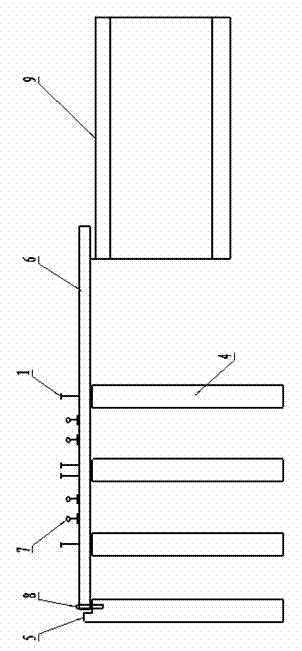

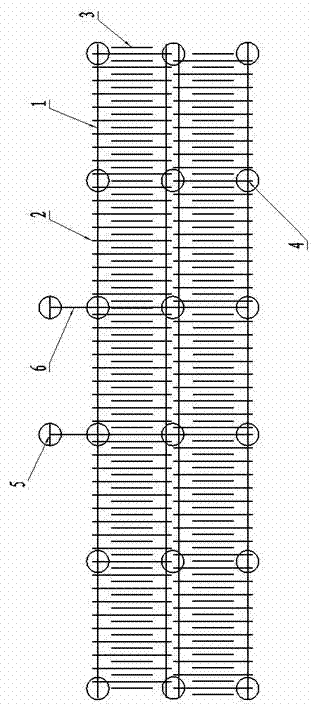

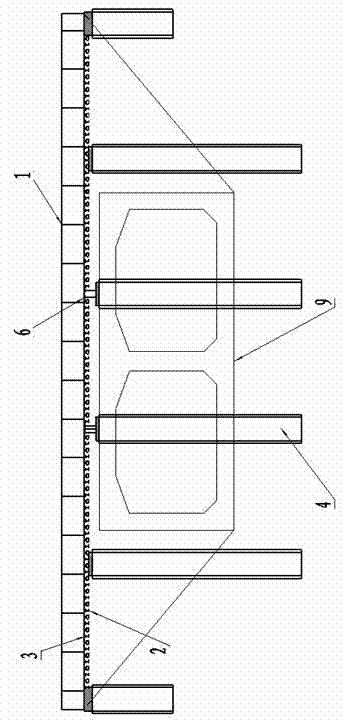

[0032] The structure of the present invention will be explained in detail below in conjunction with the accompanying drawings. The specific embodiment is a railway overhead fixing device, such as figure 2 It is a schematic plan view of the line reinforcement of the present invention, including a longitudinal beam 1 and a corbel 2, and the longitudinal beam is connected by a plurality of construction beams 10 through connecting plates and other strengths. Such as Figure 4-6 It is a structural schematic diagram of the convenient beam of the present invention; the connecting plate is composed of a web 13, an outer cover plate 11 and an inner cover plate 12, and is fixedly covered between the convenient beams, such as Figure 7 It is a schematic diagram of the connection of the utility beams into longitudinal beams in the present invention, and the utility beams are fixedly connected as a whole by bolts. The corbel beam passes through the track 7 and is parallel to the concrete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com