A construction method for three-way oblique beams

A construction method, oblique technology, applied in the direction of joists, girders, truss beams, etc., can solve the problems of uneven force, small operating space, uneconomical, etc., to improve the balance of force and reduce the span of force , Improve the effect of deflection control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

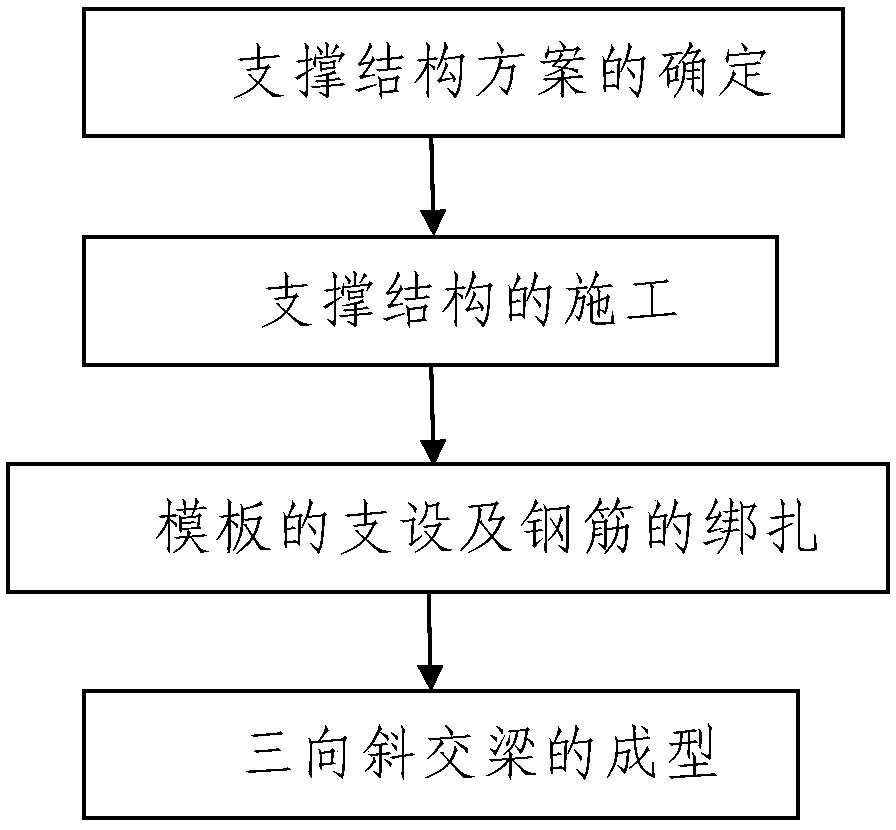

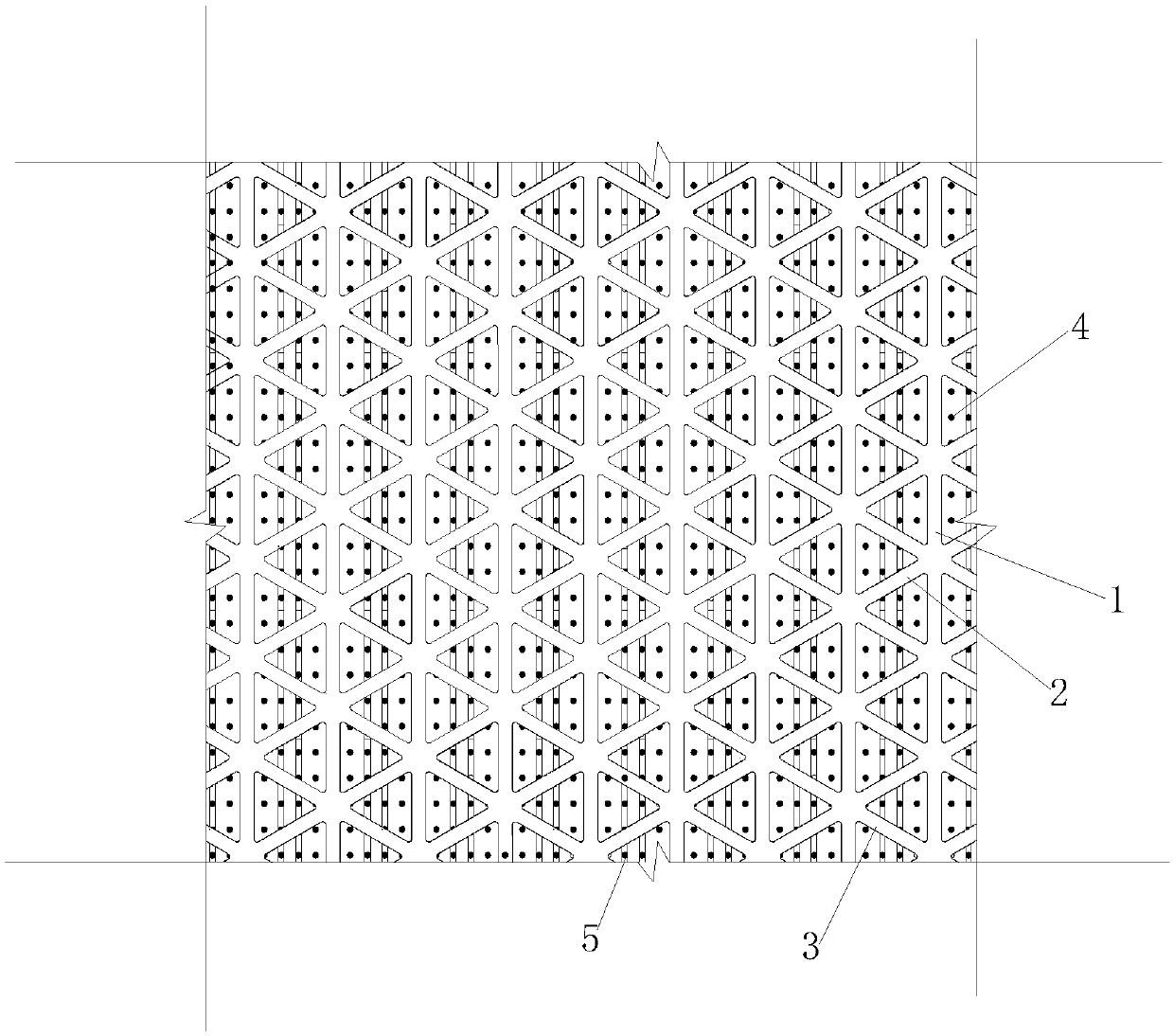

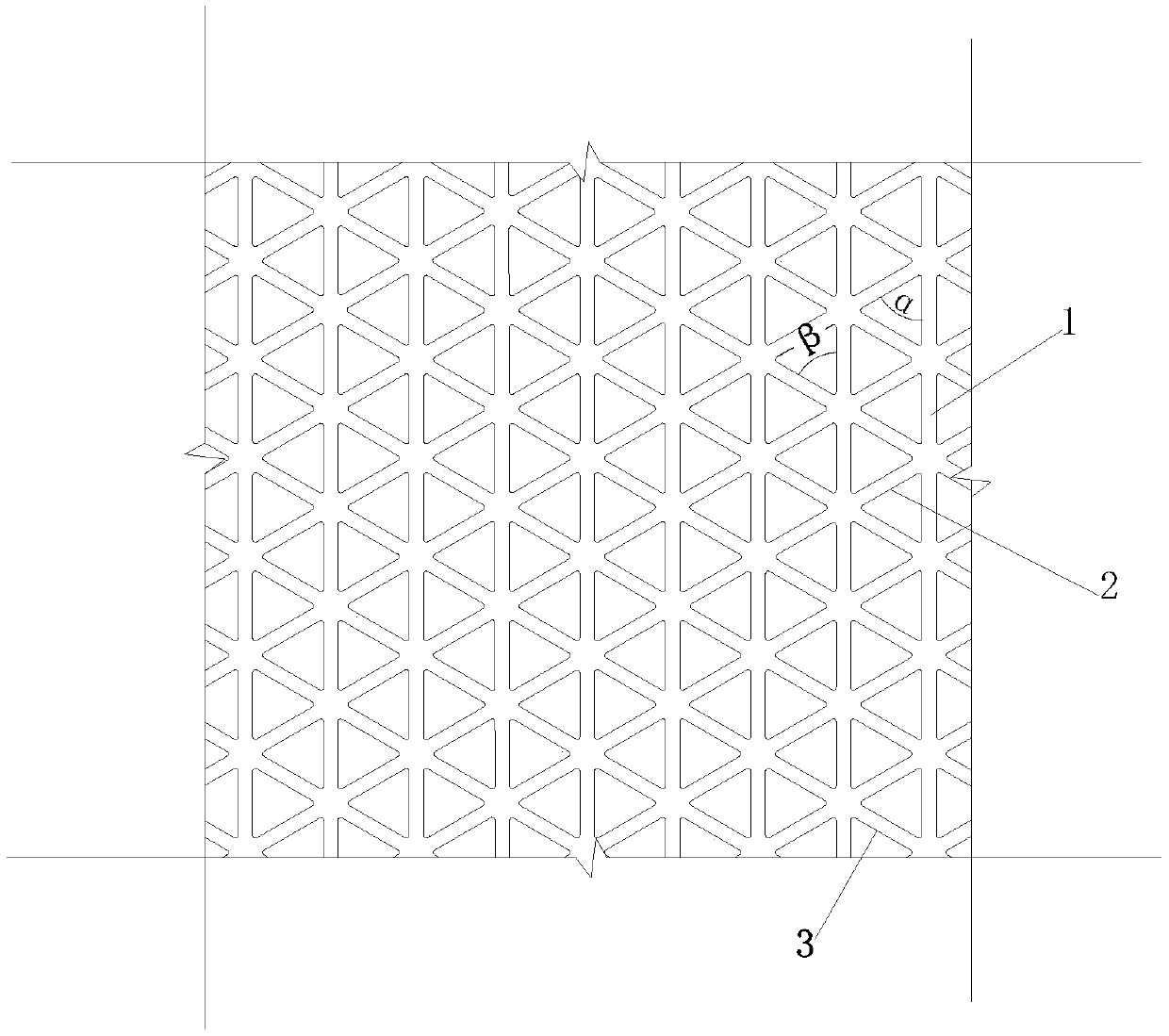

[0040] Such as Figure 1 to Figure 5 A construction method of a three-way skew beam is shown, the constructed three-way skew beam includes a plurality of parallel main beams 1, a plurality of parallel first beams 2 and a plurality of parallel second beams Beam 3, the angle between the first beam 2 and the main beam 1 is α, the angle between the second beam 3 and the main beam 1 is β, the construction method includes the following step:

[0041]Step 1. Determination of the supporting structure scheme: according to the angle α between the first beam 2 and the main beam 1 and the angle β between the second beam 3 and the main beam 1, Determine the supporting structure scheme as scaffold-shaped steel keel, determine the height of scaffold-shaped steel keel according to the constructed three-way oblique beam, the height of scaffold-shaped steel keel is less than the bottom elevation of the constructed three-way oblique beam, and the scaffold-shaped steel keel is The supporting su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com