Self-operated pressure range switching device

A range-switching, self-operated technology, applied to measuring devices, valve devices, measuring fluid pressure, etc., can solve problems such as complex structures, achieve the effects of simple and convenient pipelines, reduce maintenance costs, and improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

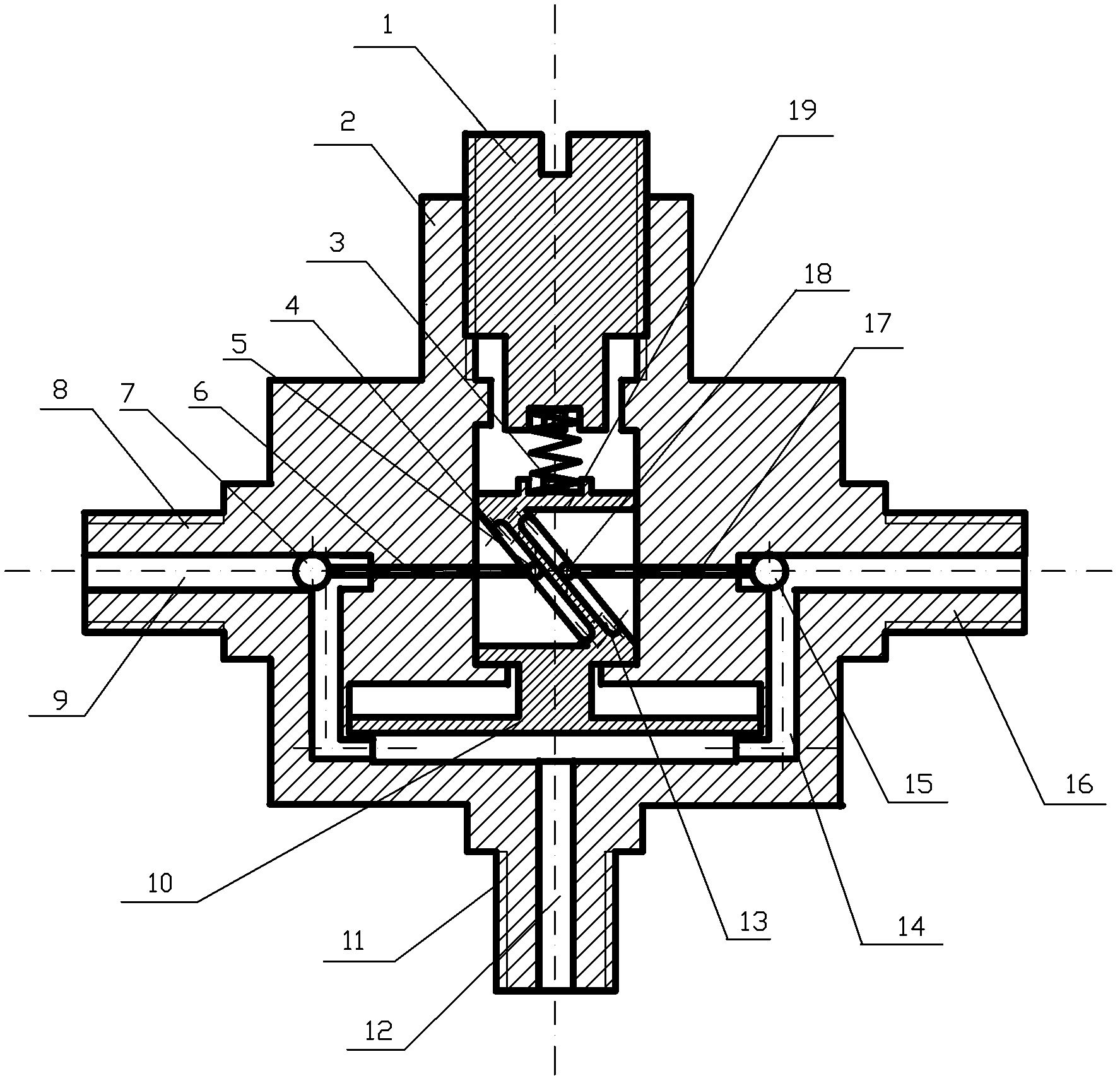

[0014] This embodiment is a self-operated pressure range switching device used for back-purging in industries such as metallurgy, thermoelectricity, and chemical industry. Its structure is as follows: figure 1 As shown, the valve body 2 has a measured pressure passage 12 communicating with the measured pressure pipe through the measuring pipe joint 11, and a high and low pressure measuring passage 9 communicating with the high and low pressure gauge heads through the high and low pressure side joints 8 and 16 respectively. , 14, the high and low pressure side joints 8, 16 are respectively located on the same horizontal line on both sides of the valve body 2, perpendicular to the measuring pipe joint 11.

[0015] The valve body 2 and the valve core 19 form a moving pair coaxial with the measured pressure channel 12; the end away from the measured pressure channel 12 is against the spring 3, and the end of the spring away from the valve core is against the screwed on On the set ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com