Evaluation method of 10kV three-core cable conductor temperature

A three-core cable and conductor temperature technology, applied to the direction of the thermometer that gives the difference, can solve the problems of large errors, harsh calculation conditions, and insufficient universality, and achieve simplified calculations, wide applicability, and guaranteed calculation accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

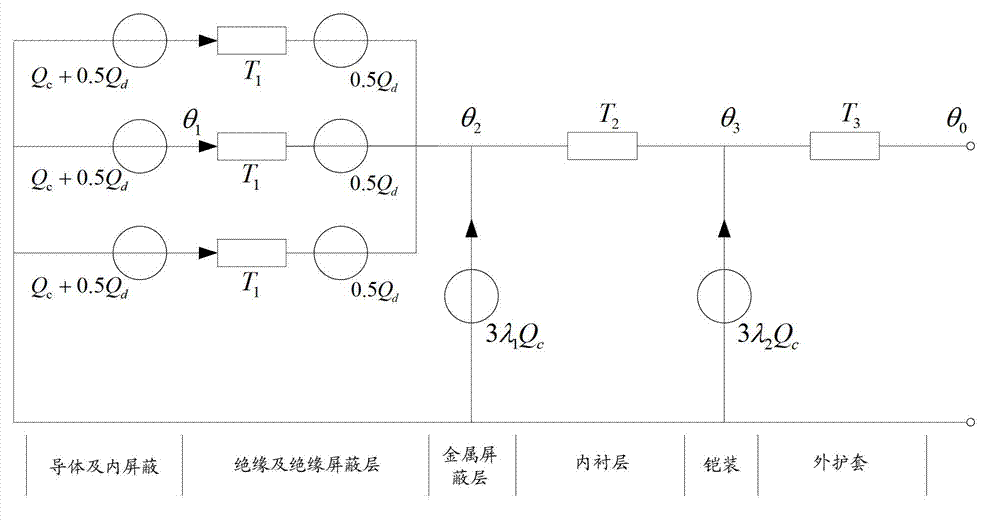

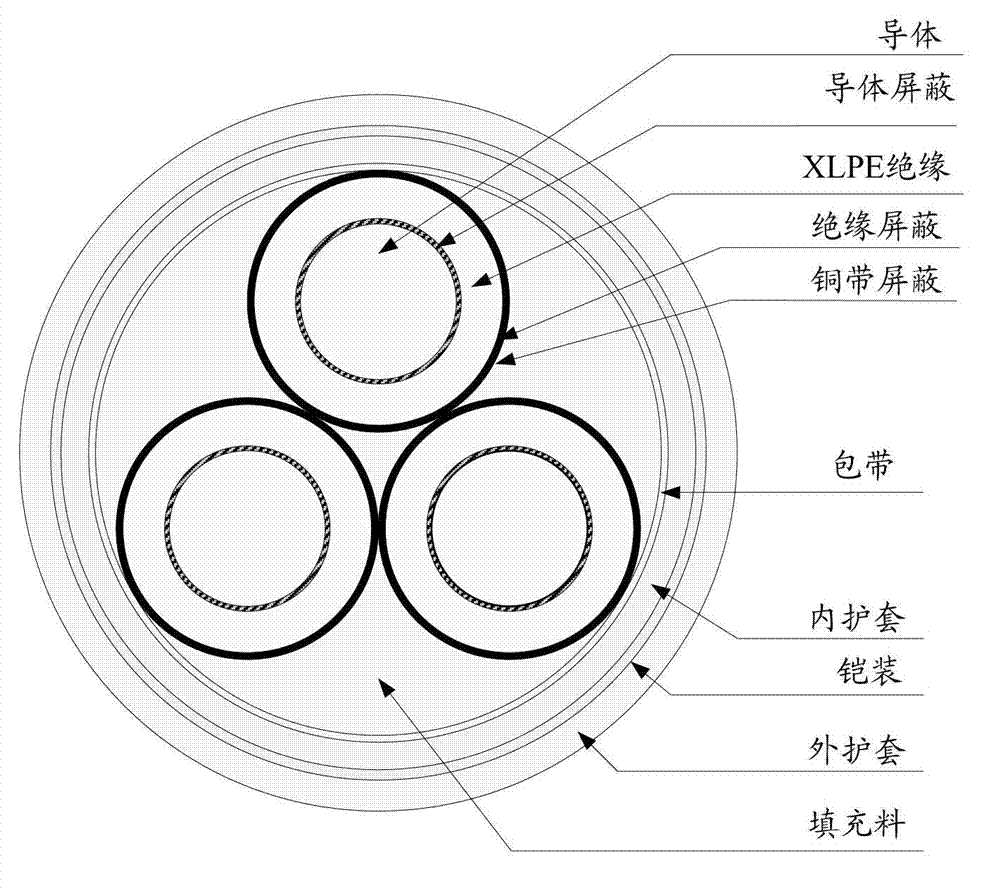

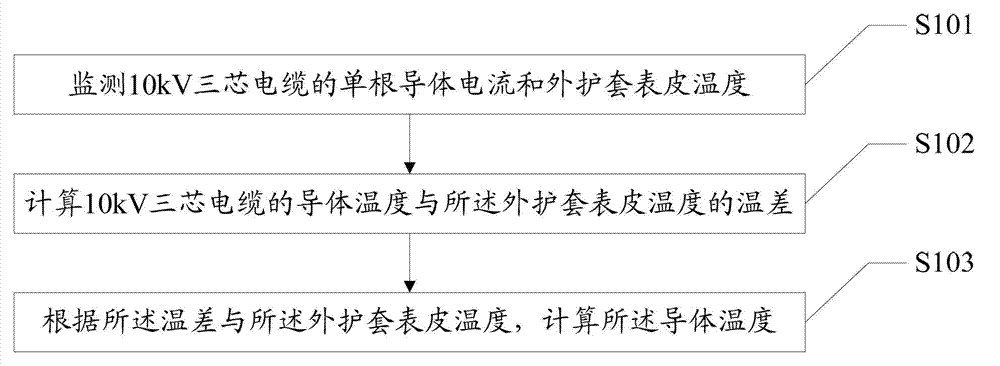

[0023] At present, there are basically two methods to determine the current carrying capacity of a 10kV three-core cable: one is to use the IEC60287 standard, under the conditions of 100% load and typical laying methods, part of the experience value is used to calculate the steady-state current carrying capacity; the other is Carry out the current-carrying capacity experiment under the condition of the same cable load current for laying multiple rows of pipes, and determine the current-carrying capacity of the cable group during actual operation through the experiment. The present invention proposes a new idea in calculating the steady-state conductor temperature of a 10kV three-core cable and determining the current carrying capacity: eliminating the need for the traditional ambient temperature measurement when calculating the current carrying capacity and not considering the changeable environmental thermal resistance, and each in the cable group It can also be calculated unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com