Back-to-back paired mounting angular contact ball bearing parameter combination measuring device

A technology of measuring device and parameter combination, applied in the field of measuring device of angular contact ball bearing parameters, to achieve the effect of overcoming uncertainty and blindness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

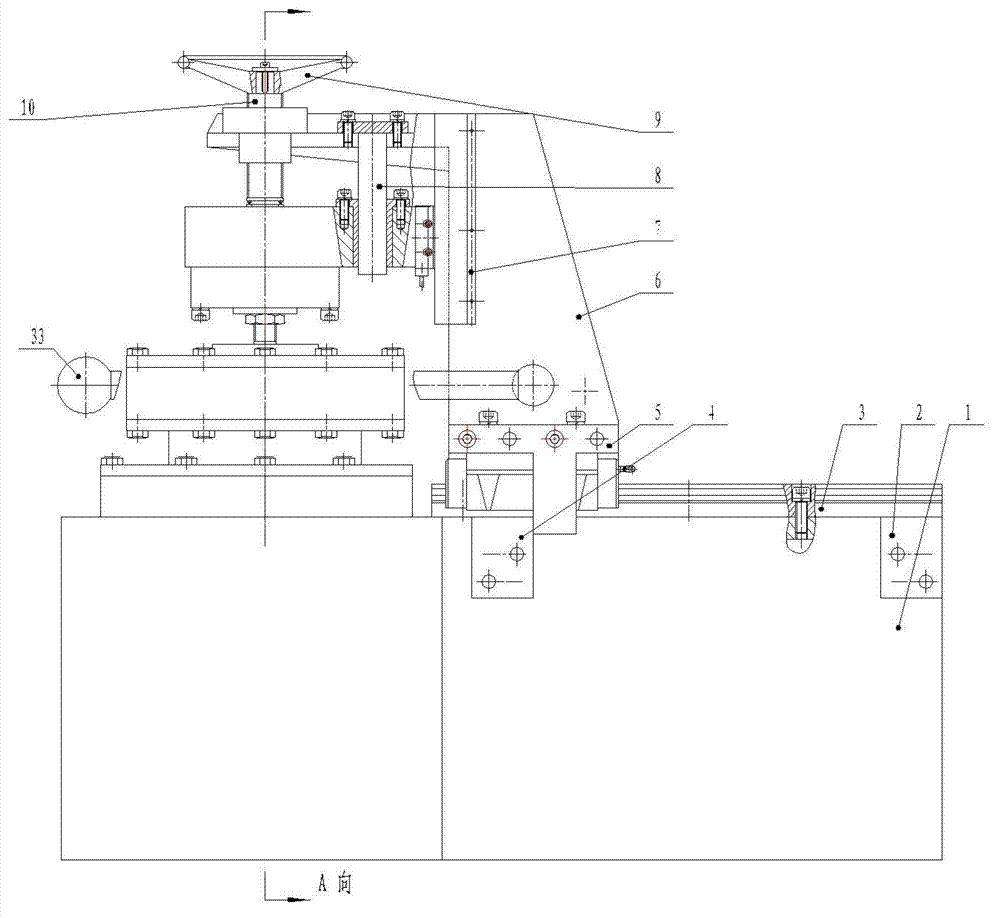

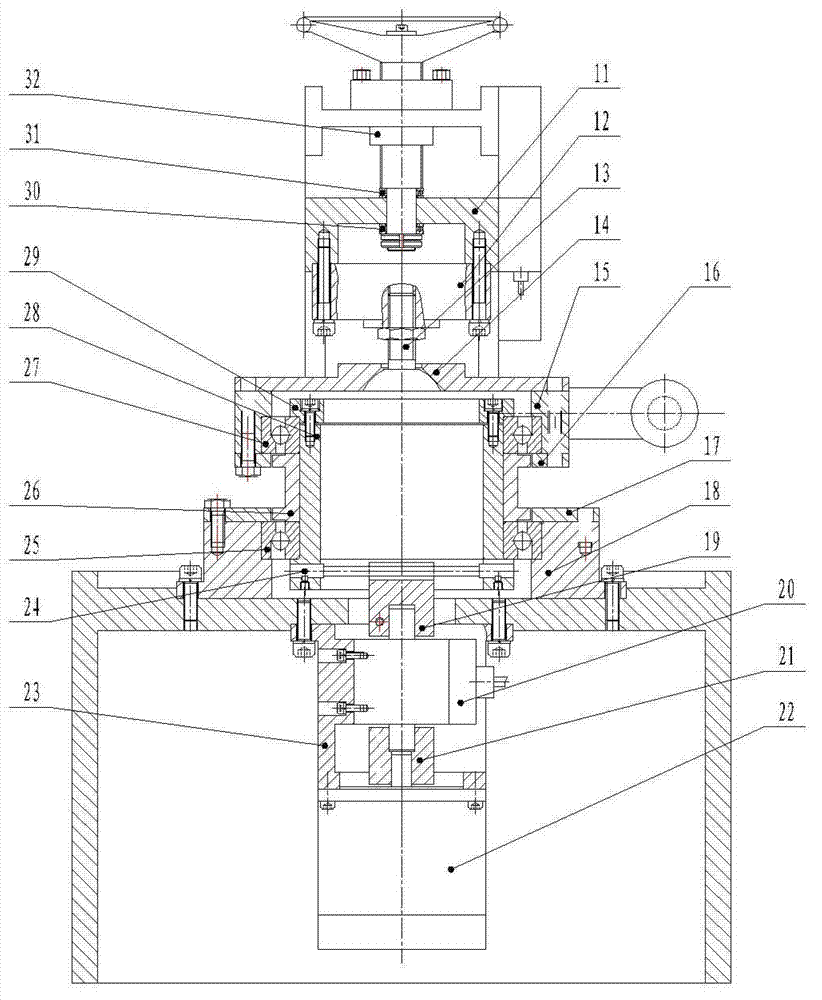

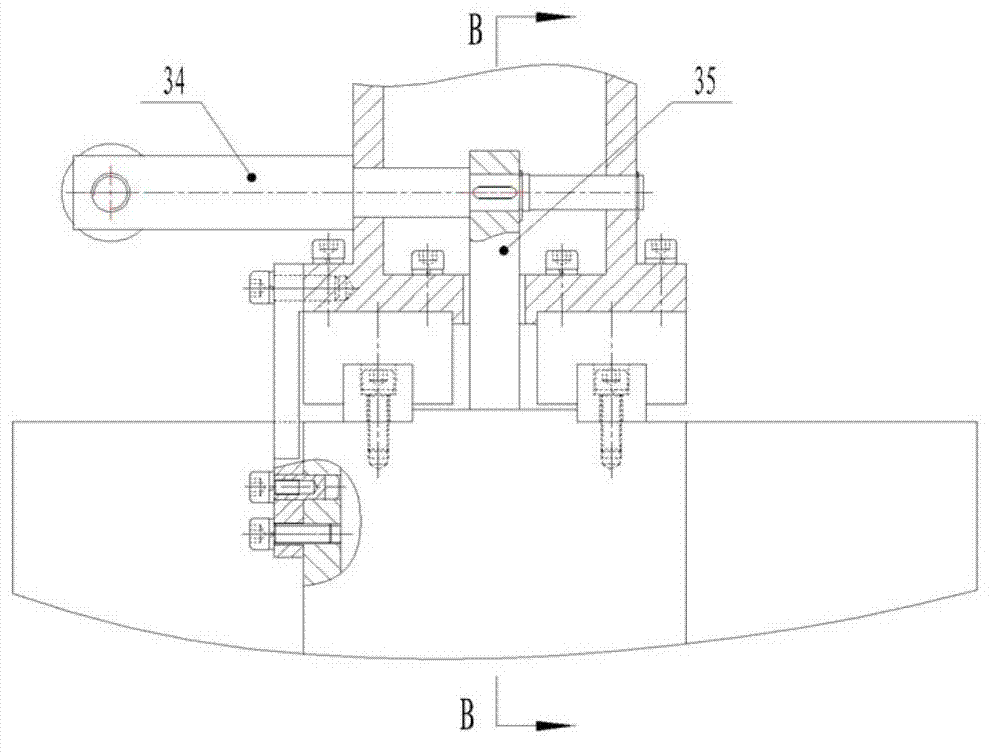

[0023] Such as Figure 1-Figure 4 As shown, the combined measurement device for back-to-back angular contact ball bearings with back-to-back installation in pairs, relative displacement, and rotational friction torque is measured from top to bottom by the pulling and sensing mechanism, bearing mounting base, transmission and rotational friction torque The organization consists of three parts.

[0024] The pulling and sensing detection mechanism is connected and installed on the rolling linear guide rail pair 3 of the bearing installation base by the column 6, and can move along the rolling linear guide rail pair, and its position is determined by the positioning block 4, the travel limit block 5, and the rear limit block 2. Position, to adapt to the measurement of bearings of different specifications; the transmission and rotation friction torque measurement mechanism is installed on the base 1 in the bearing installation base part through the motor base 23, and the pull in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com