Counterweight guide mechanism for vehicle door lock test equipment

A technology of test equipment and guiding mechanism, which is used in vehicle testing, machine/structural component testing, measuring devices, etc., to achieve the effects of stability assurance, stable and reliable operation, and reliability assurance of test data.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

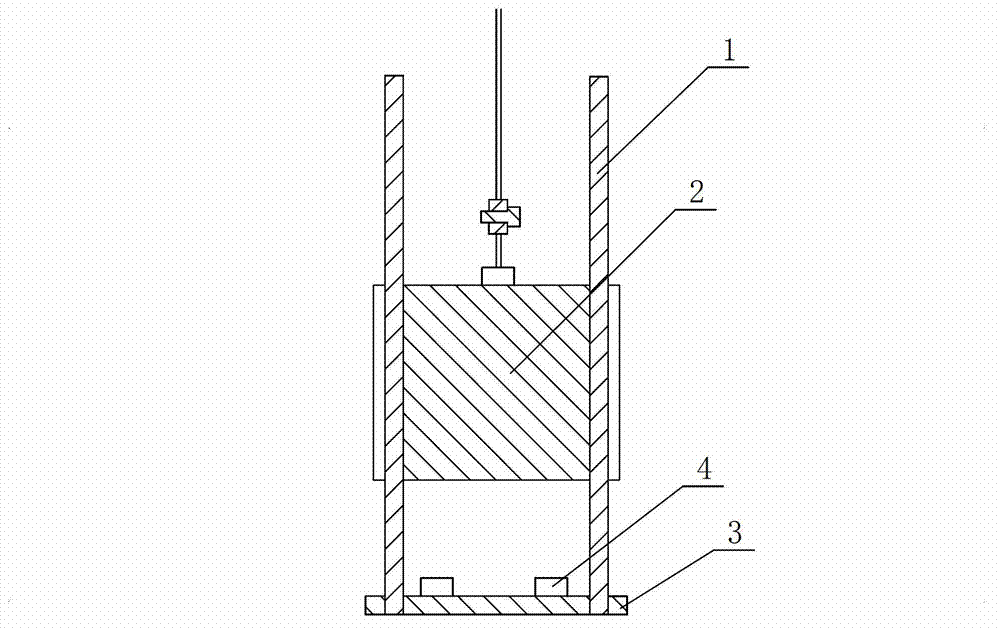

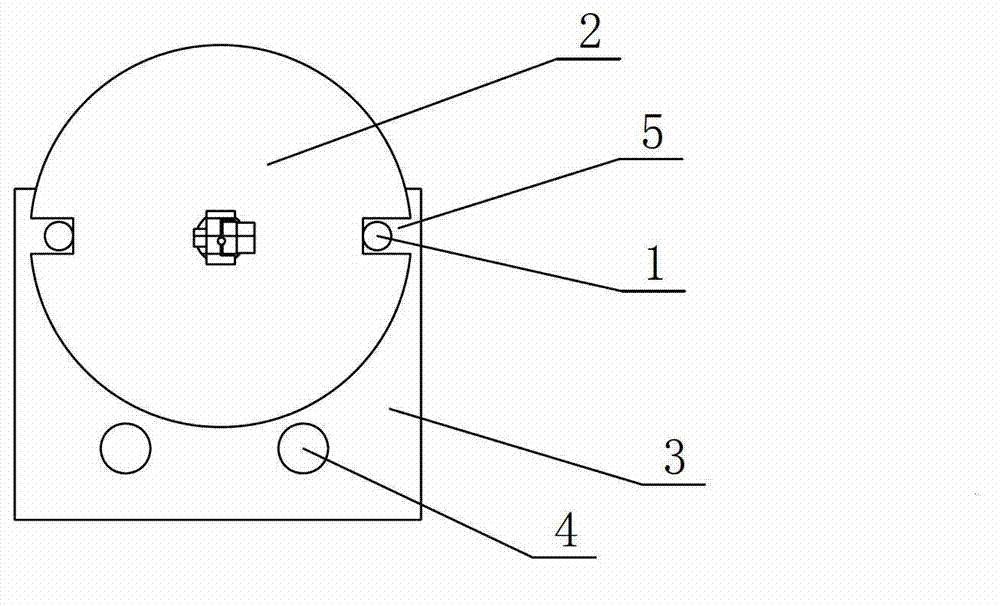

[0015] see figure 1 and figure 2 As shown, a counterweight guide mechanism for automobile door lock test equipment includes a counterweight 2, the bottom of the counterweight 2 is provided with a guide and positioning base plate 3, and two cylinders are fixed on the guide and positioning base 3 The guide column 1 of the body is matched with the guide column 1 and correspondingly provided with two elongated guide grooves 5 on the cylindrical surface of the counterweight 2. The guide grooves 5 pass through the upper and lower sides of the counterweight 2, and with The center of the counterweight 2 is symmetrically arranged at a point of symmetry, the guide column 1 is arranged in the guide groove 5, and the guide and positioning base plate 3 is provided with a fixing column 4 for fixing it to the au...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com