Method for detecting shielding layer of capacitive touch screen

A technology of capacitive touch screen and detection method, which is applied in the direction of measuring device, measuring electrical variable, measuring resistance/reactance/impedance, etc., can solve problems such as damage and inaccurate function test results, achieve high efficiency, avoid secondary damage, The effect of high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

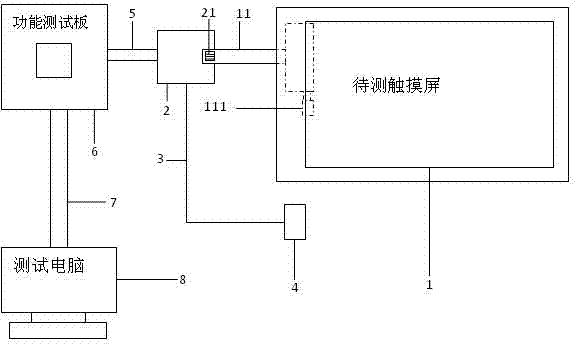

[0022] In order to understand the present invention more clearly, describe the present invention in detail in conjunction with accompanying drawing and embodiment:

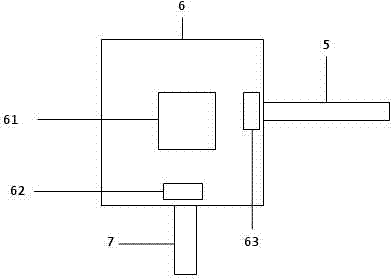

[0023] Such as figure 1 , figure 2 As shown, the detection hardware of the capacitive touch screen shielding layer includes a test computer 8, a functional test board 6 and a functional test adapter board 2 with capacitive touch screen test software installed, and simulates the FPC (printed flexible circuit board) with conductive material 4 ) The shielding pin of 11 is used to detect the shielding layer of touch screen 1 to be tested;

[0024] Function test board 6 comprises single-chip microcomputer 61, IIC / SPI communication interface 62 and USB communication interface 63;

[0025] The functional test adapter board 2 is made of a double-layer printed circuit board, which is used for line transfer, and a connector 21 is welded on it. The functional test board 6 is connected to the test computer 8 through the U...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com