Defect rate detecting method of oil immersed type main transformer

A technology of main transformer and detection method, applied in the direction of instruments, measuring electricity, measuring devices, etc., can solve problems such as power outages and losses in the power grid, and achieve the effects of avoiding equipment failures, enhancing availability, and reducing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

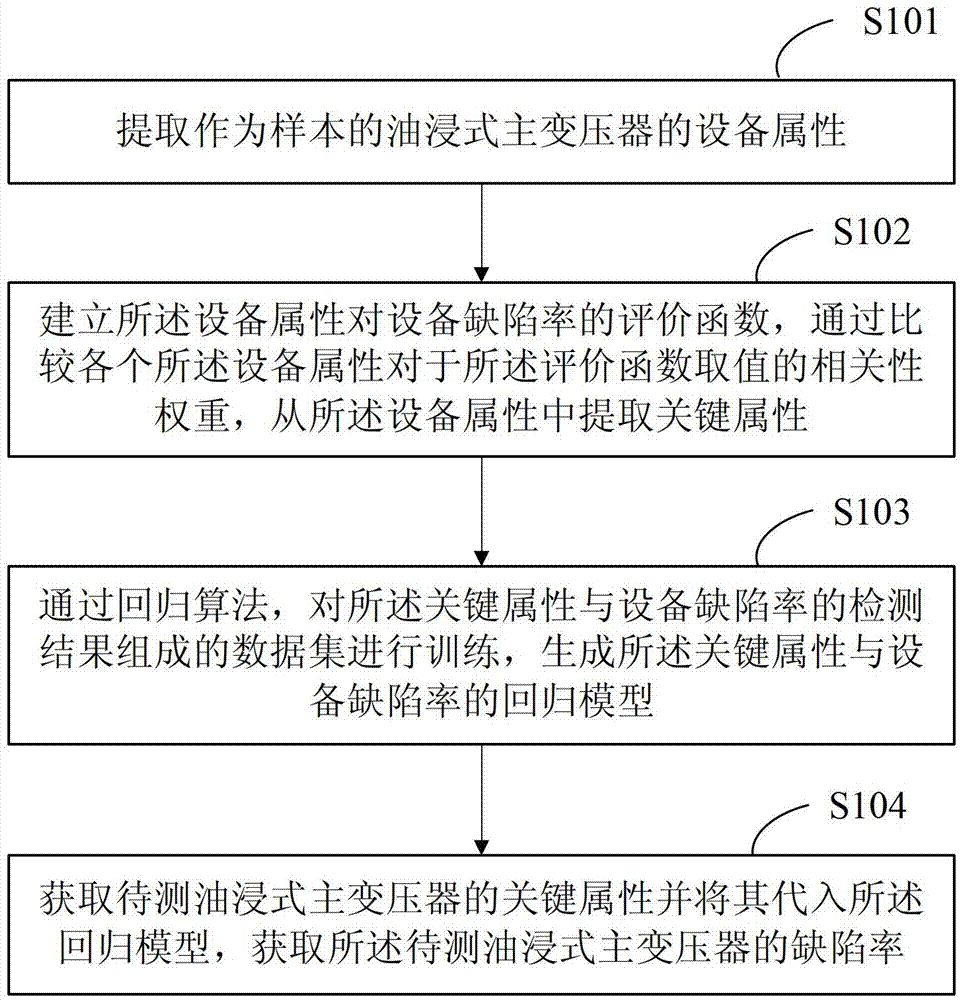

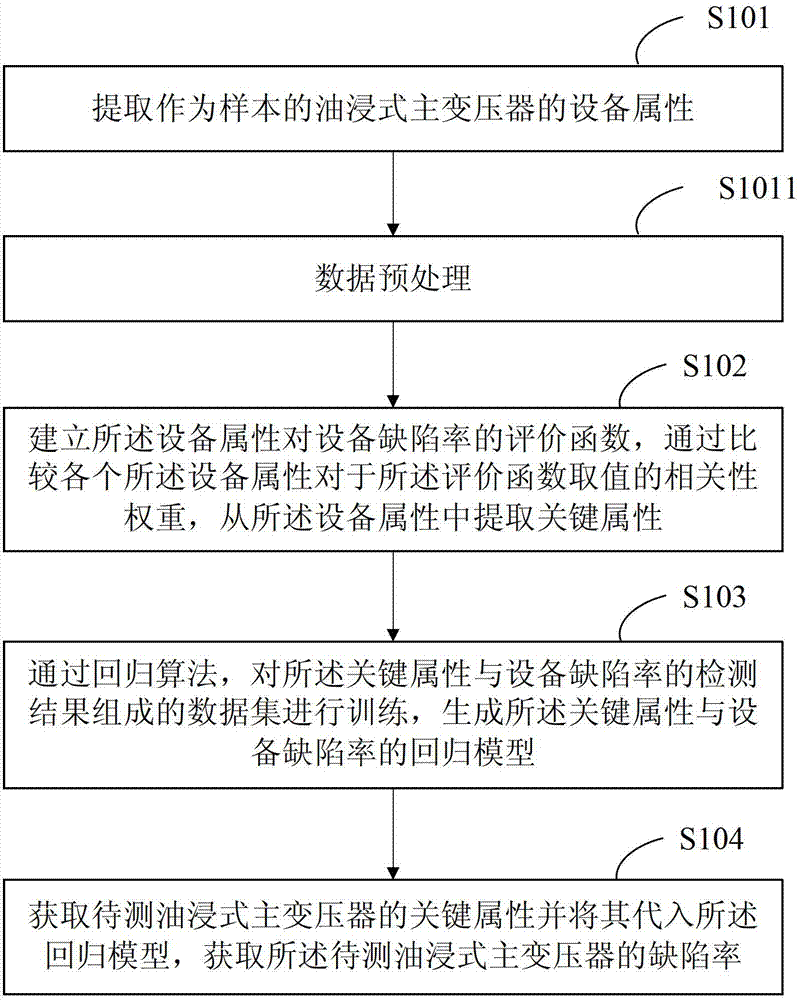

[0015] see figure 1 , figure 1 It is a schematic flow chart of the defect rate detection method of the oil-immersed main transformer of the present invention.

[0016] The defect rate detection method of the oil-immersed main transformer comprises the following steps:

[0017] S101, extracting equipment attributes of the oil-immersed main transformer as a sample;

[0018] S102, establishing an evaluation function of the equipment attribute on the equipment defect rate, and extracting key attributes from the equipment attributes by comparing the correlation weights of each of the equipment attributes with respect to the value of the evaluation function;

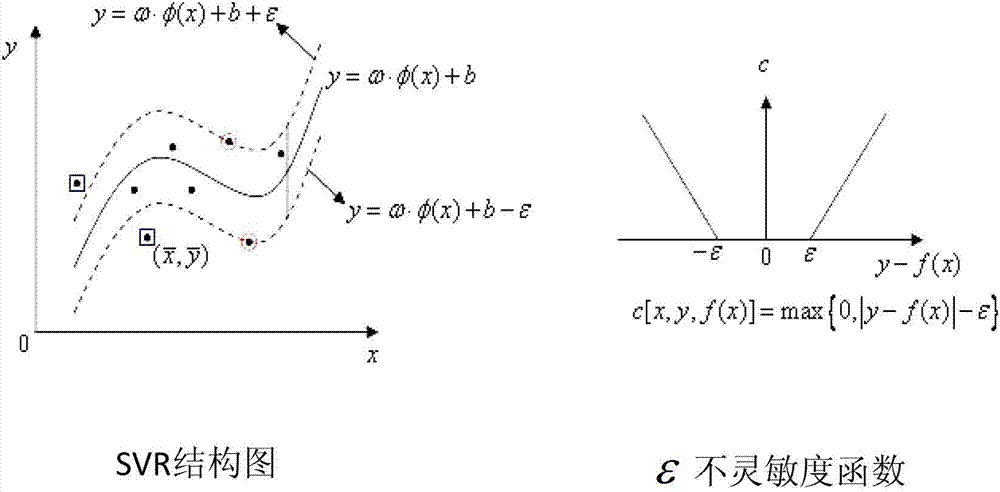

[0019] S103. Using a regression algorithm, train the data set composed of the key attribute and the detection result of the equipment defect rate, and generate a regression model of the key attribute and the equipment defect rate;

[0020] S104. Obtain key attributes of the oil-immersed main transformer to be tested and sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com