Conducting wire fixer for 10kV live working

A live work and wire fixing technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of high labor intensity, unsafe, inconvenient to bind and fix wires, etc., and achieve the effect of reducing labor intensity, safe live work, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

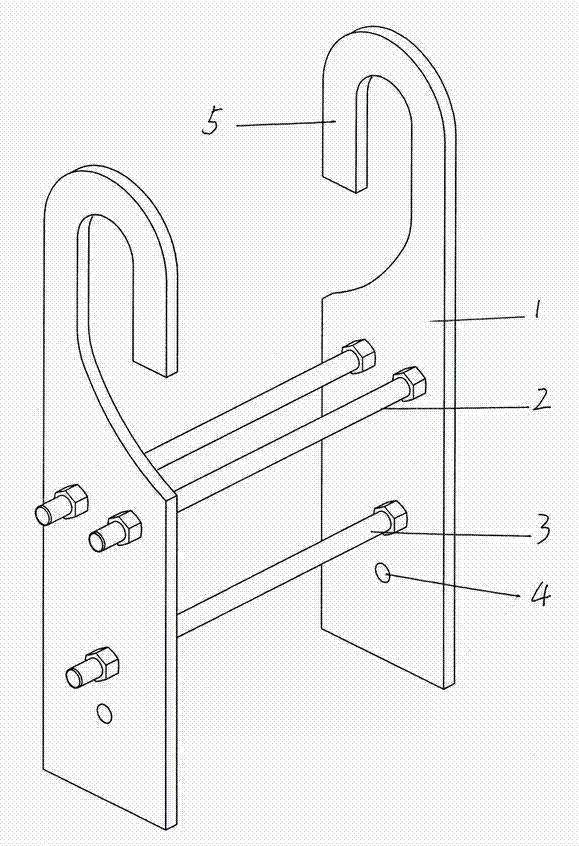

[0007] The embodiment is described in detail in conjunction with the above accompanying drawings. The 10kV live working wire insulation fixer of the present invention is to be connected with two insulating screw rods 2 in parallel at equal heights between the upper and middle parts of each board surface of two insulating hanging boards 1. The insulating hanging plate above the insulating screw rod is respectively provided with a hook 5 with a hanger opening to the inside. The height of the concrete rod cross arm and the insulator are respectively provided with two adjustment holes 4 up and down, and an insulating lifting screw 3 can be selectively connected in the two pairs of adjustment holes corresponding to each other. Insulating jackscrews can be installed in a pair of upper adjustment holes (e.g. figure 1 shown), it can also be installed in a pair of lower adjustment holes, and the specific installation position depends on the site conditions. During use, this fixer is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com