Microcapsule-type latent curing agent for epoxy resin and process for production thereof

A technology for epoxy resin and manufacturing method, which is applied in the direction of microcapsule preparation, microsphere preparation, etc., which can solve the problems of inability to mix in large quantities in advance, complicated storage and operation, and limited service life, and achieve excellent storage stability and good storage Stability and productivity improvement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

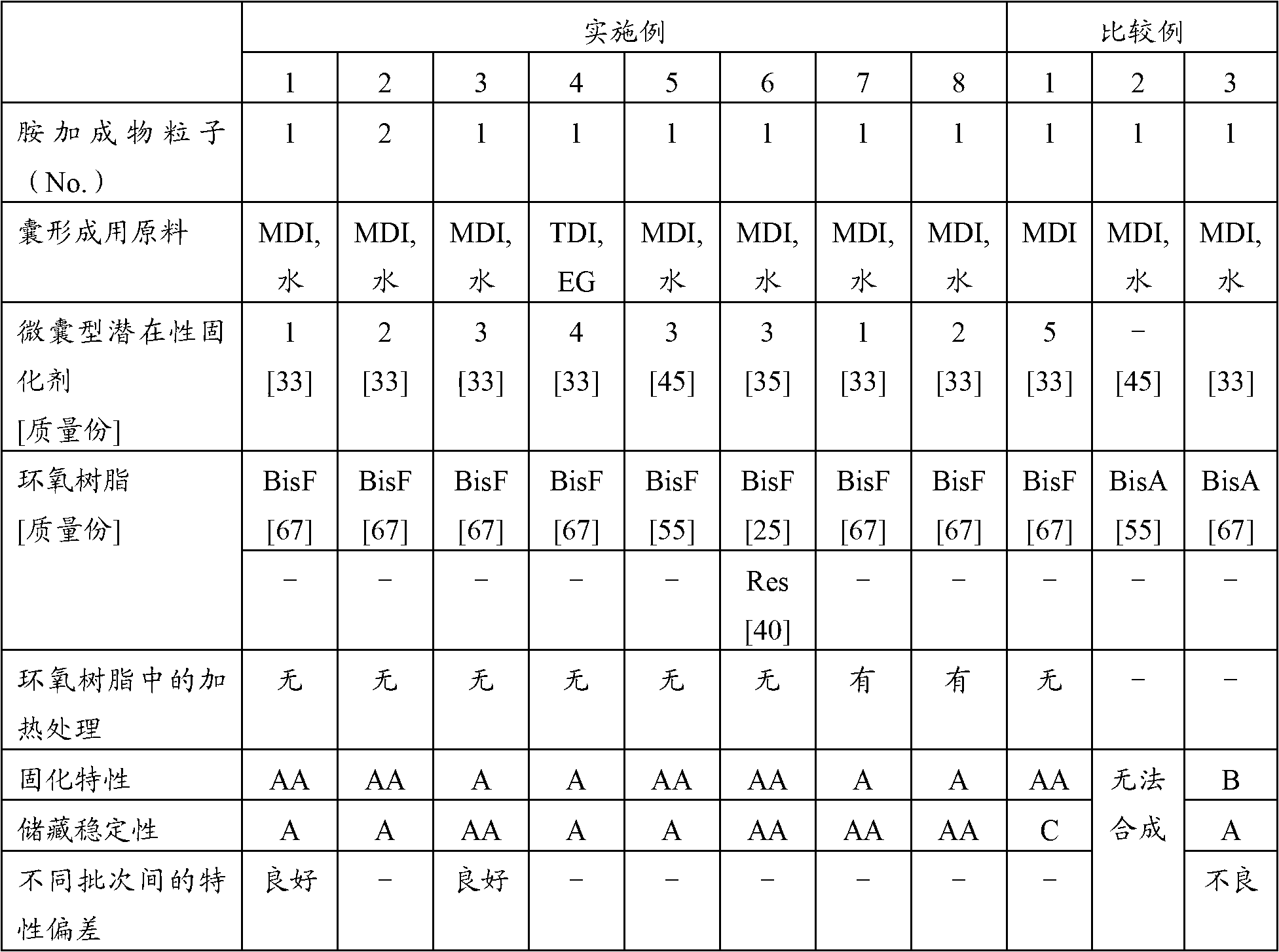

Embodiment 1~3

[0108] Cooperate with 33g microcapsule latent curing agent 1, 2 or 3, and 67g bisphenol F type epoxy resin (epoxy equivalent is 160g / eq, hydrolyzed chlorine content is 0.007% by weight), obtains one of embodiment 1~3 Liquid epoxy resin composition.

Embodiment 4

[0110] 33 g of microcapsule latent curing agent 4 and 67 g of bisphenol A epoxy resin (epoxy equivalent: 173 g / eq, hydrolyzed chlorine content: 0.01% by weight) were mixed to obtain a one-component epoxy resin composition.

Embodiment 5

[0112] 45 g of microcapsule latent curing agent 3 and 55 g of bisphenol F epoxy resin (epoxy equivalent: 160 g / eq, hydrolyzed chlorine content: 0.007% by weight) were mixed to obtain a one-component epoxy resin composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com