Multifunctional wrench applicable to narrow operation space

An operating space and multi-functional technology, applied in the direction of wrenches, manufacturing tools, screwdrivers, etc., can solve the problems of components affecting the accuracy of equipment assembly, adverse effects of equipment normal operation, increasing the workload of maintenance personnel, etc., to shorten the maintenance time, The effect of avoiding disassembly and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

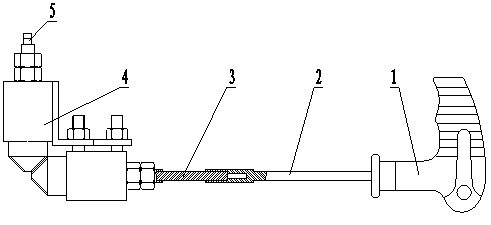

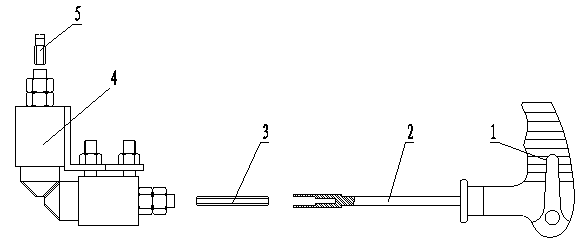

[0017] See Figure 1, figure 2 , the present invention includes a handle 1, a lever arm 2, a connecting rod 3, a bevel gear steering mechanism 4 and a connecting head 5. Assembling, the rear end of the connecting rod 3 is assembled with the front end of the bevel gear steering mechanism 4, the rear end of the bevel gear steering mechanism 4 is assembled with the connecting head 5, and the connecting head 5 is connected with the threaded connector to be disassembled match.

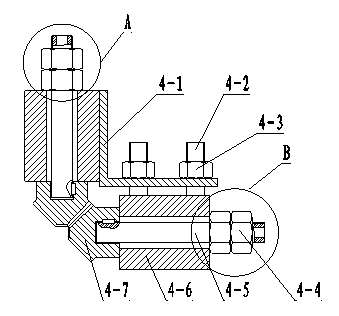

[0018] see image 3 , Figure 4 , Figure 5 , the bevel gear steering mechanism 4 of the present invention comprises a pair of bevel gear assemblies, an L-shaped mounting bracket 4-1 and a stud assembly that are meshed with each other, and the bevel gear assembly consists of a bevel gear 4-7, a gear shaft 4-5, Composed of sleeve 4-6 and double lock nut 4-4, the bevel gear 4-7 is fixed on one end of the gear shaft 4-5, and the gear shaft 4-5 passes through the sleeve 4-6 in the form of clearance fit Aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com