Variable frequency hydraulic coupling cable drum

A cable reel and hydraulic coupling technology, applied in the field of power supply devices for mobile equipment, can solve the problems of unsatisfactory effect, shorten the service life of the cable, damage to the cable sheath, etc., to solve the problem of rapid response, prolong the service life, Low maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

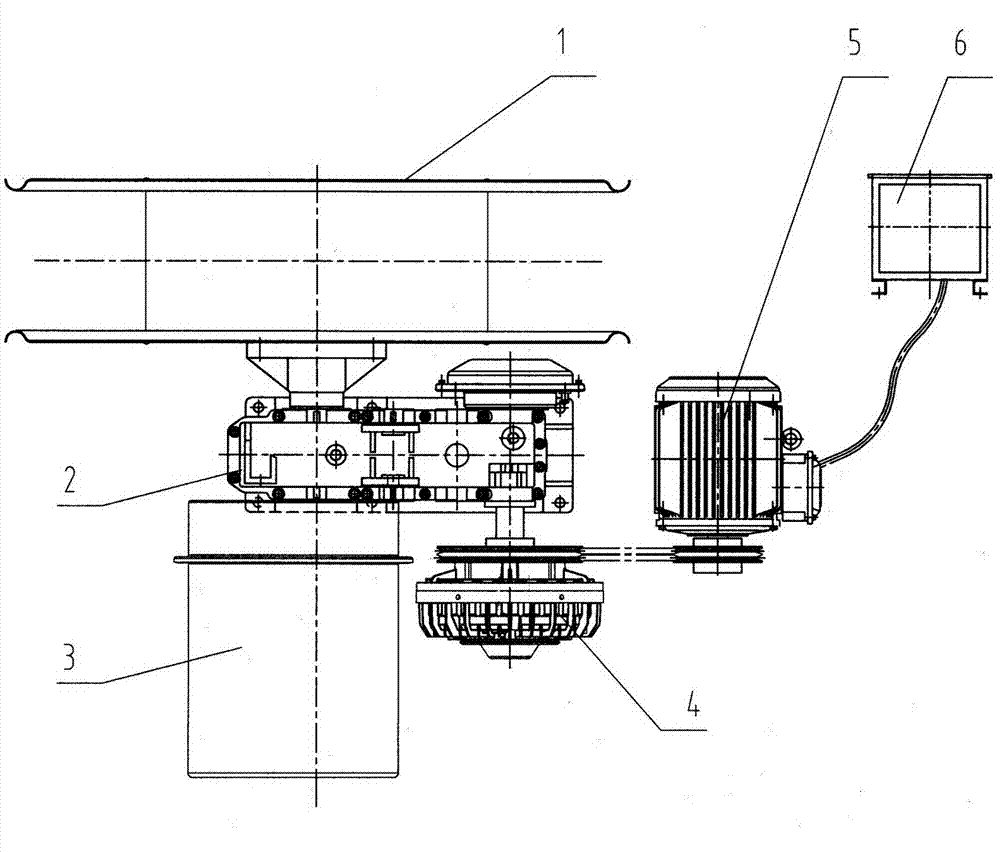

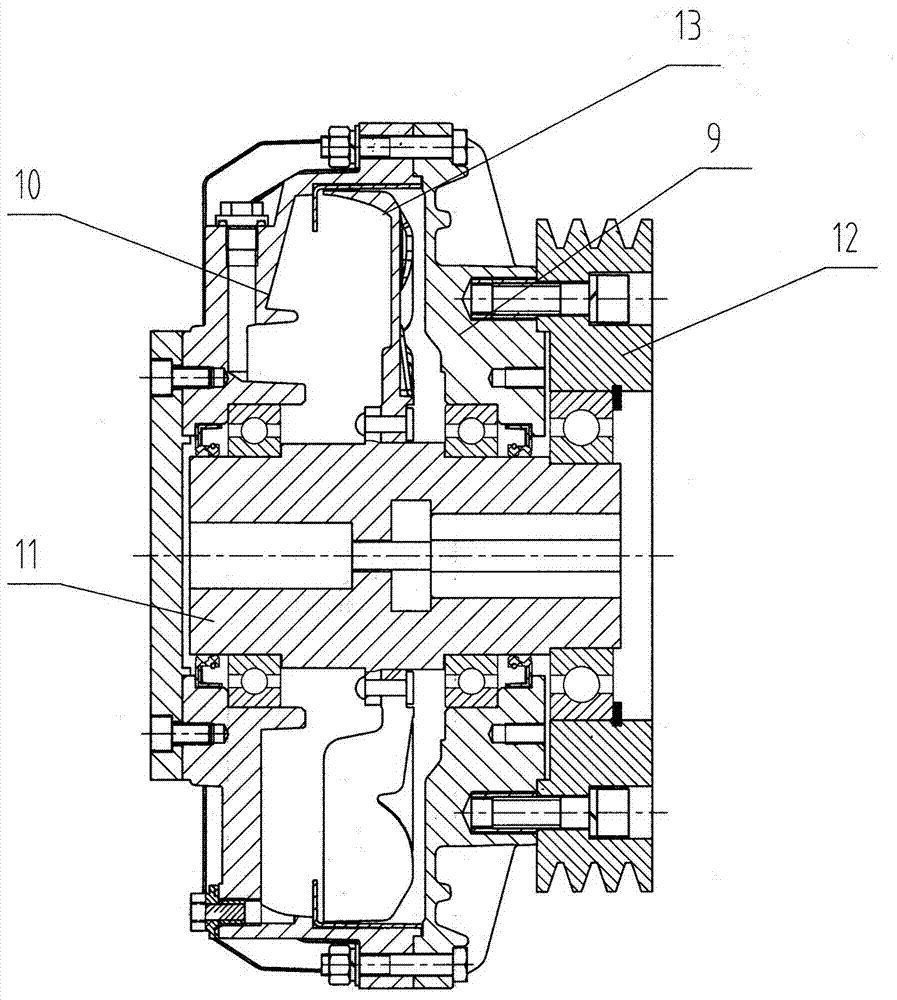

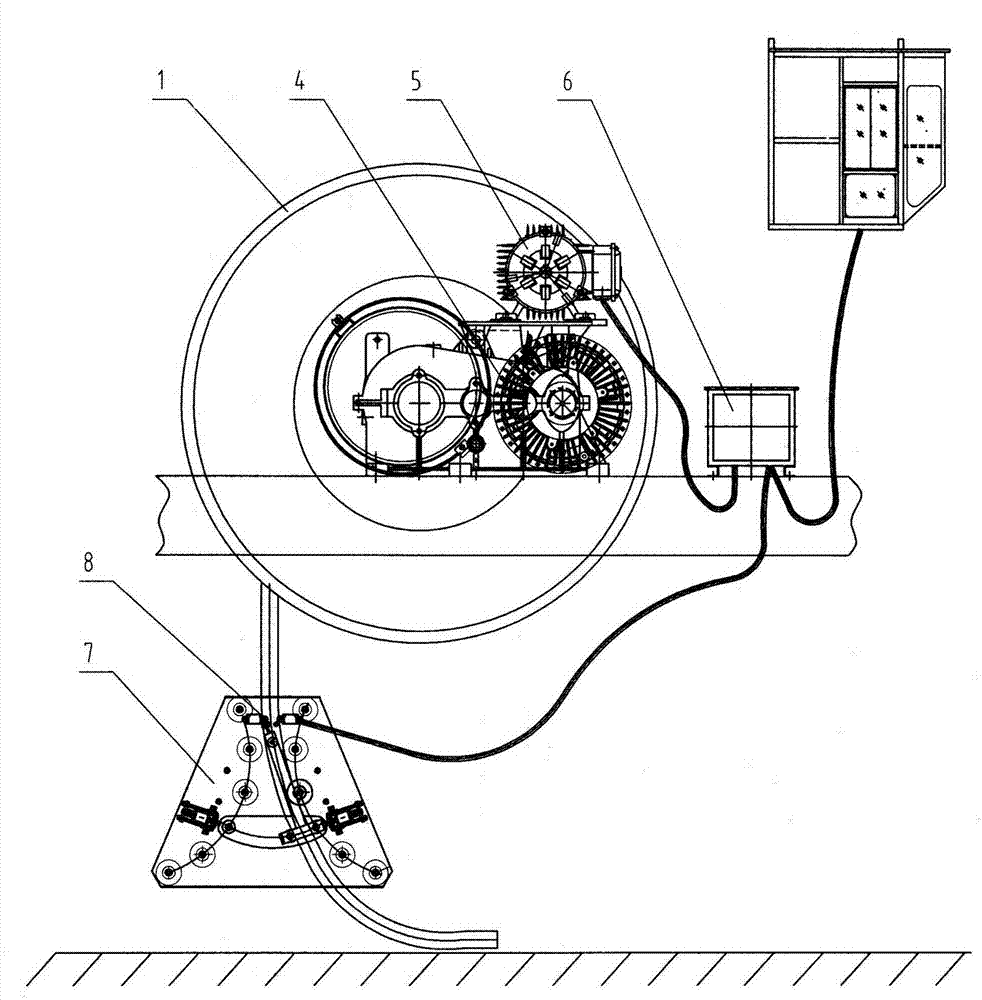

[0017] Depend on Figures 1 to 3 It can be seen that the present invention includes a cable reel body 1, a cable guide 7 arranged on the cable reel of a mobile device, and a drive system for driving the action of the cable reel body 1. The drive system is composed of a headstock 2, a hydraulic A flexible drive system composed of a coupler 4 and a variable frequency electrical controller 6, wherein:

[0018] The hydraulic coupling 4 is connected to the drive motor 5 through a belt or a rigid coupling, and the drive motor 5 is connected to the frequency conversion electrical controller 6 through a conductor, and the frequency conversion electrical controller 6 is connected to and receives signals from the fairlead 7 and the command center and converts them into electrical signals. The frequency is transmitted to the drive motor 5 through the conductor. The drive motor 5 receives the electric frequency and generates a corresponding speed to drive the fluid coupling 4 to rotate. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com