Leveling system for high-altitude operation platform by means of PWM (pulse-width modulation) control technology

A high-altitude work platform and control technology technology, which is applied in the field of high-altitude work platform control, can solve the problems of unsuitability for telescopic booms and hybrid booms, high processing requirements for structural parts, poor leveling stability, etc., and achieve a small and beautiful appearance , Leveling system advanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

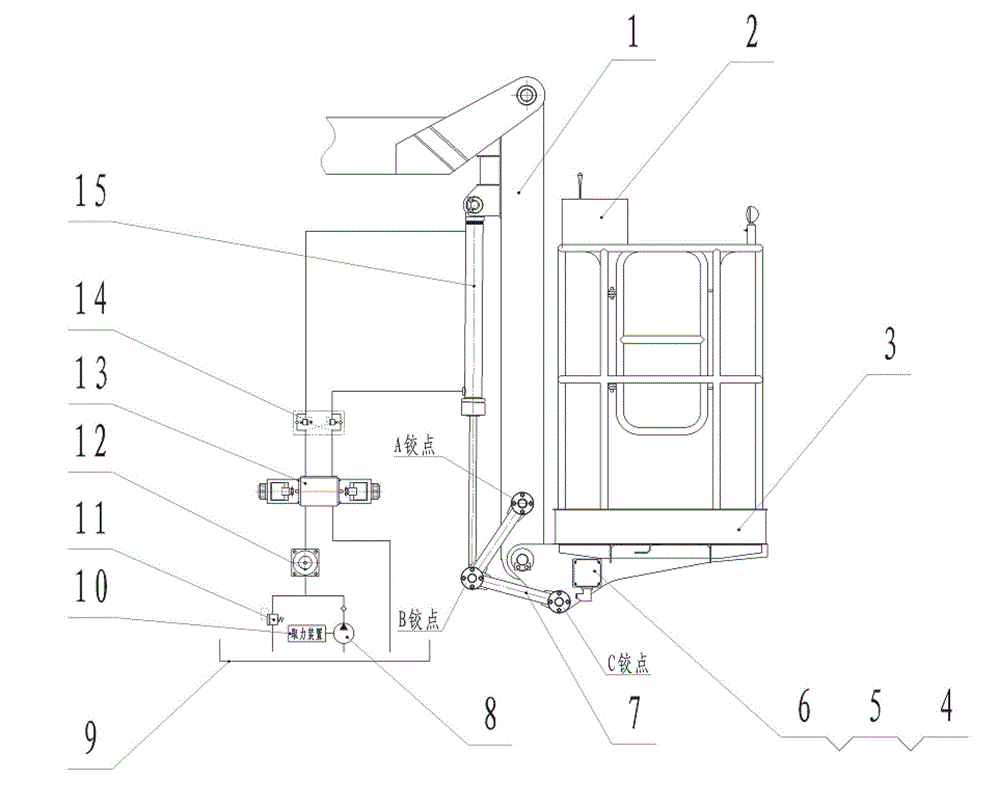

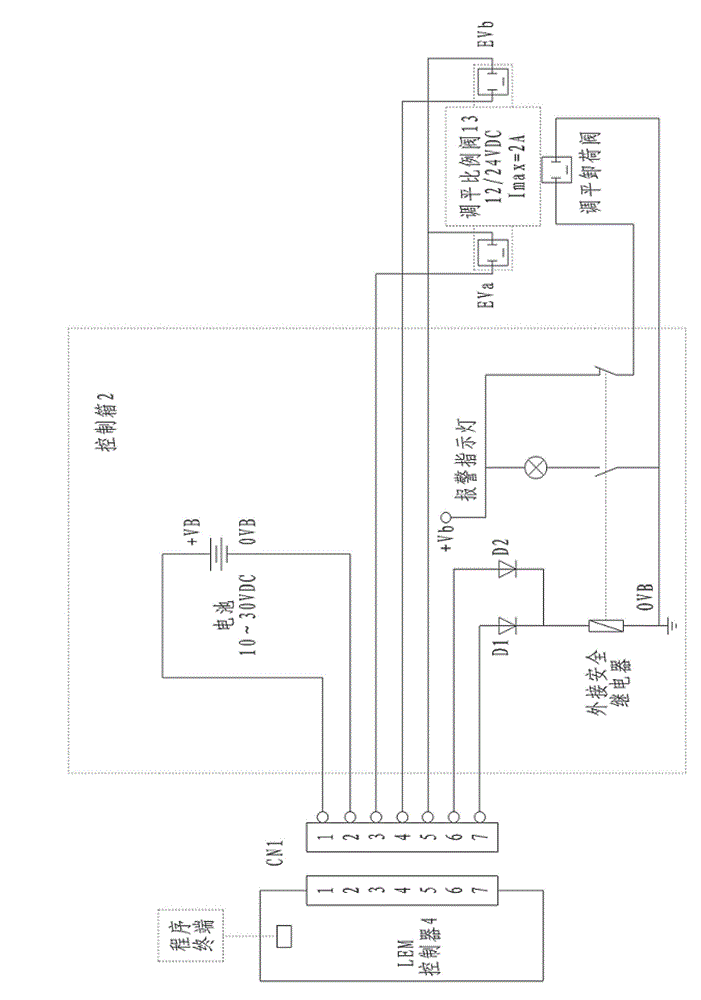

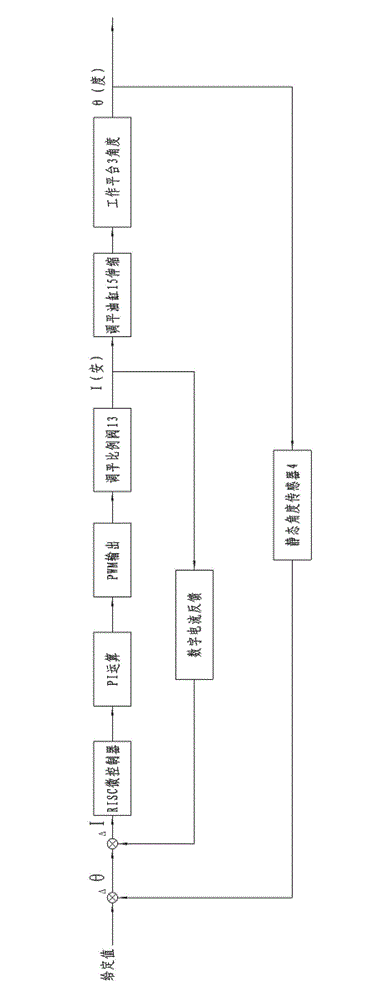

[0017] see figure 1 Shown is a leveling system of an aerial work platform applying PWM control technology, the leveling system includes a support arm 1, a control box 2, an aerial work platform 3, a LEM controller 4, a static angle sensor 5, and a mercury angle switch 6 , connecting plate 7, oil pump 8, fuel tank 9, power take-off device 10, speed regulating valve 12, safety valve 11, leveling proportional valve 13, two-way speed limiting valve 14 and leveling oil cylinder 15.

[0018] The connecting plate 7 has three hinge points A, B, and C. The hinge point A of the connecting plate 7 is hinged with the lower end of the support arm 1, the hinge point B of the connecting plate 7 is hinged with the working end of the leveling cylinder 15, and the C of the connecting plate 7 is hinged. The point is hinged with the bottom of the aerial work platform 3 . Leveling oil cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com