Cold cathode plant growth lamp

A plant growth lamp, cold cathode technology, applied in the directions of botanical equipment and methods, parts and applications of gas discharge lamps, can solve the problems of lamp brightness attenuation, short life, fast light decay, etc., to prevent visual fatigue , long service life, good color rendering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

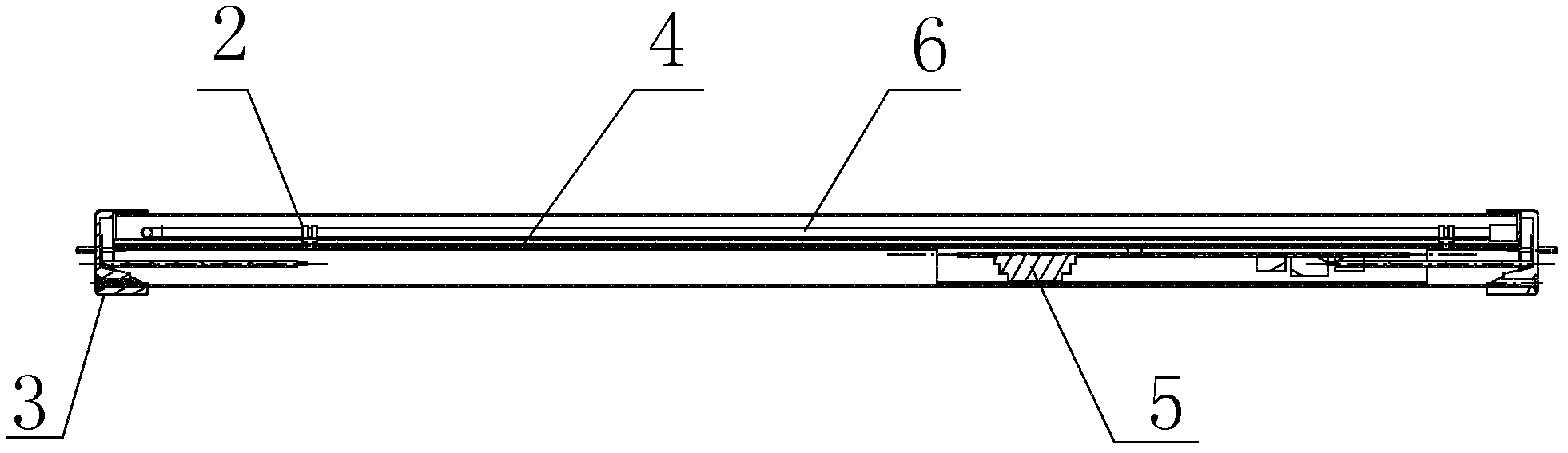

[0019] A cold cathode plant growth lamp, comprising an outer tube 1, a cold cathode lamp tube 6, the outer tube 1 is provided with a reflector 4, the fluorescent powder used in the cold cathode lamp tube 6 is made of special red and blue phosphor powder, and the cold cathode lamp tube 6 is made of special red and blue phosphor powder. The lamp tube 6 is installed on one side of the reflective sheet 4 through the tube clip 2, and the other side of the reflective sheet 4 is equipped with an inverter 5, and the output end of the inverter 5 is electrically connected with the cold cathode lamp tube 6, and the inverter 5 The input end of the lamp is led out to both ends of the outer tube 1 through the lamp cap 3 .

[0020] The outer tube 1 adopts a T5, T8 or T10 specification, so that the existing T5, T8 or T10 specification lamp holder can be used and directly clamped on the existing lamp holder, thereby saving cost. The working side of the reflective sheet 4 referred to here is ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com