Ball screw pair reliability test stand provided with electro-hydraulic servo loading devices

A ball screw pair and loading device technology, which is applied in the direction of machine gear/transmission mechanism testing, etc., can solve the problems that the reliability test cannot be carried out, and the reliability test device cannot simulate the actual working conditions, so as to achieve real-time monitoring and force testing. And displacement closed-loop control and feedback, the effect of high loading accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is described in detail below in conjunction with accompanying drawing:

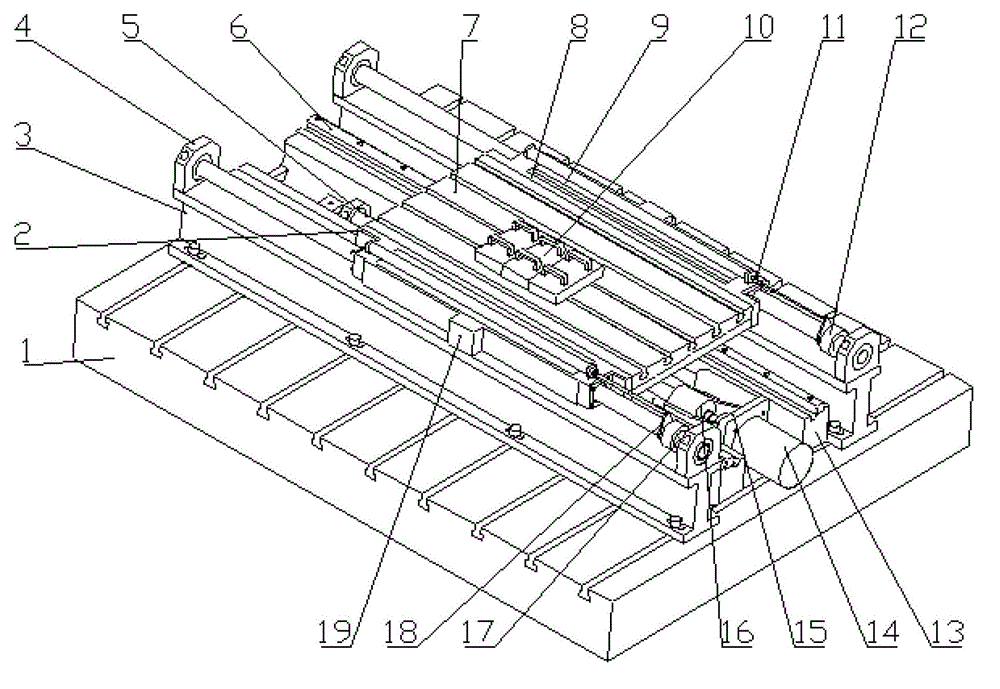

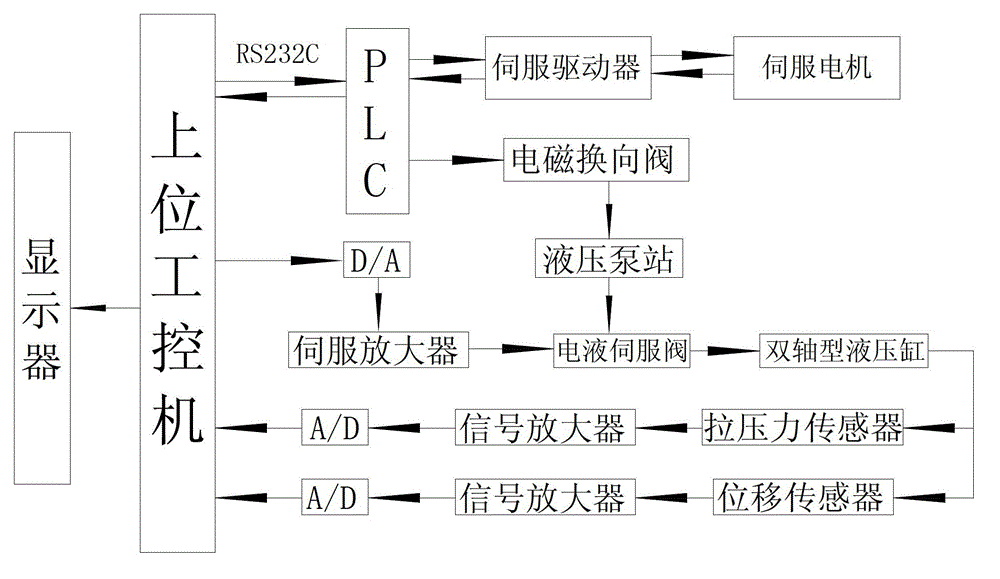

[0027] refer to figure 1 , The ball screw reliability test bench with electro-hydraulic servo loading device of the present invention is composed of a ball screw driving part, a load applying part and an automatic control part.

[0028] 1. The drive part of the ball screw

[0029] The driving part of the ball screw pair consists of a servo motor 14, a servo motor base 15, a coupling 16, a ball screw auxiliary screw, a nut, a nut seat 5, 2 bearings, 2 bearing seats, and 2 sets of rolling guide rail pairs , including guide rail, slide block 6, slide seat 13, horizontal iron 1 and workbench 7 to form.

[0030] The cross-section of the slide seat 13 is "concave" type, and the two sides protruding from the slide seat 13 are provided with threaded holes for installing guide rails. Through the through hole fixed on the horizontal iron 1 through the T-type nut.

[0031] The slidin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com