High-speed one-way tensile test device and method

A technology of unidirectional tension and testing equipment, which is applied in the direction of measuring equipment, using stable tension/pressure testing material strength, instruments, etc., which can solve the problem of expensive Hopkinson tension rod experimental equipment and difficulty in obtaining stress-strain relationship curves , can not directly give the constitutive relationship of materials and other issues, to achieve the effect of low cost, convenient experimental conditions, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

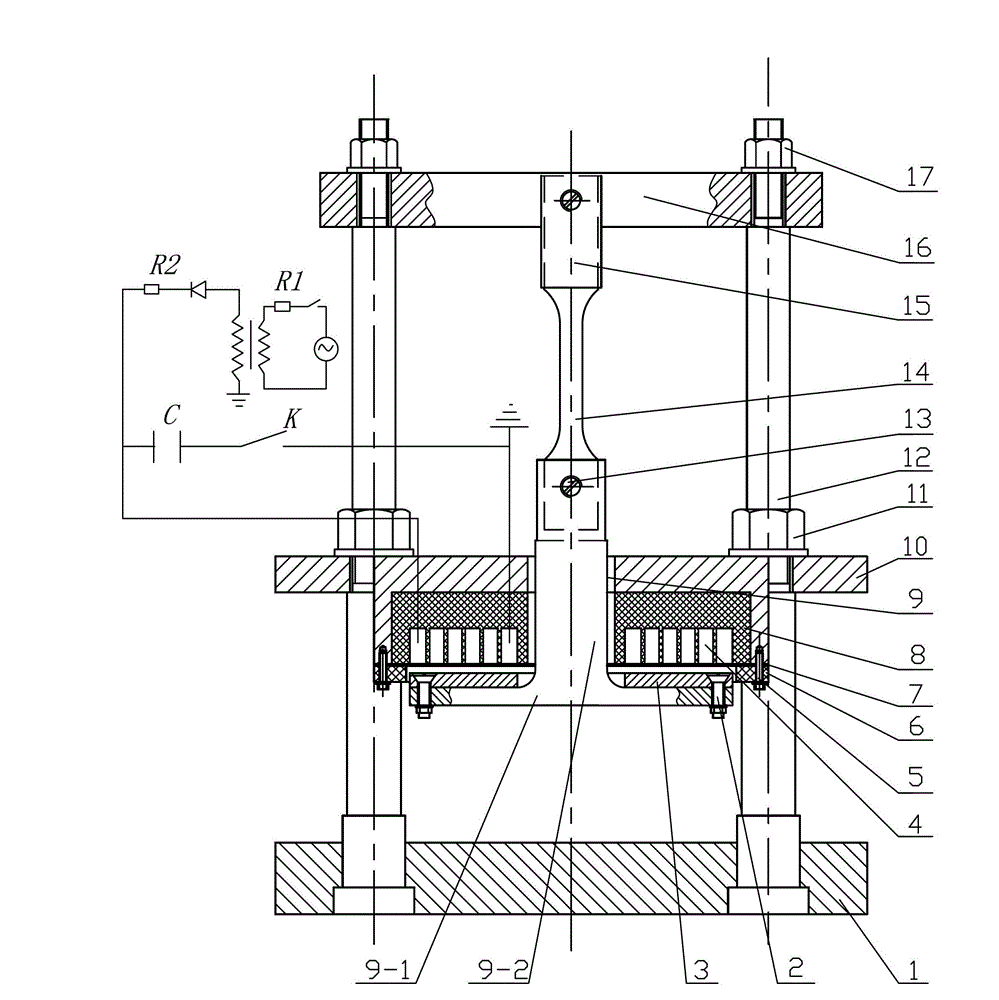

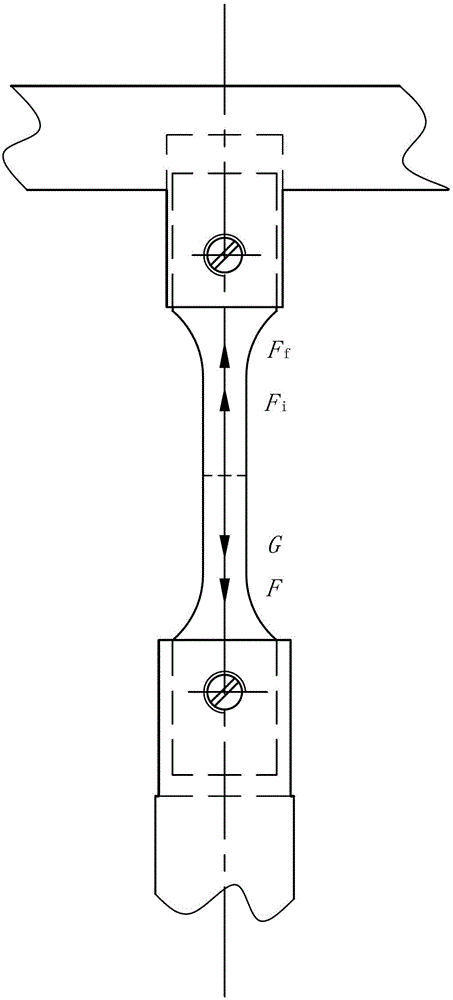

[0029] Specific implementation mode one: combine figure 1 and figure 2 Description, a high-speed unidirectional tensile test device, the device includes a base plate 1, a driving piece 3, a coil 4, a rigid coil stop ring 6, an insulating partition 7, a tensile mold 9, a coil support sleeve 10, a test Sample fixing plate 16 and two pull rods 12;

[0030] The center of the coil support sleeve 10 is provided with a connected inner shoulder hole and a through hole from bottom to top, the coil 4 is fixed in the inner shoulder hole of the coil support sleeve 10, and the sample fixing plate 16 is arranged on the front of the coil support sleeve 10 Above, the bottom plate 1 is arranged directly below the coil support sleeve 10, and the two pull rods 12 are arranged symmetrically with respect to the vertical center line of the base 1. The sample fixed plate 16 is detachably connected, and the lower end of the coil support sleeve 10 is provided with a rigid coil limit ring 6, and an ...

specific Embodiment approach 2

[0031] Specific implementation mode two: combination figure 1 Explain that the coil 4 described in this embodiment is a flat coil, the wire of the coil 4 is a copper wire, the cross section of the copper wire is rectangular, there is a gap between two adjacent copper wires, and a high voltage is used between the copper wires and the copper wires. Insulation cladding separates. The undisclosed technical features in this embodiment are the same as those in the first embodiment.

specific Embodiment approach 3

[0032] Specific implementation mode three: combination figure 1 To illustrate, the driving piece 3 in this embodiment is a red copper plate with a thickness of 5-8 mm. The undisclosed technical features in this embodiment are the same as those in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com