Sealing structure of terminal of lead-acid storage battery

A technology of lead-acid battery and sealed structure, which is applied in the direction of structural parts, battery pack parts, circuits, etc., can solve the problems of battery leakage, welding trouble, electrolyte spread, etc., to simplify the production process, save production costs, improve Effects on battery reliability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention is further illustrated below by way of examples.

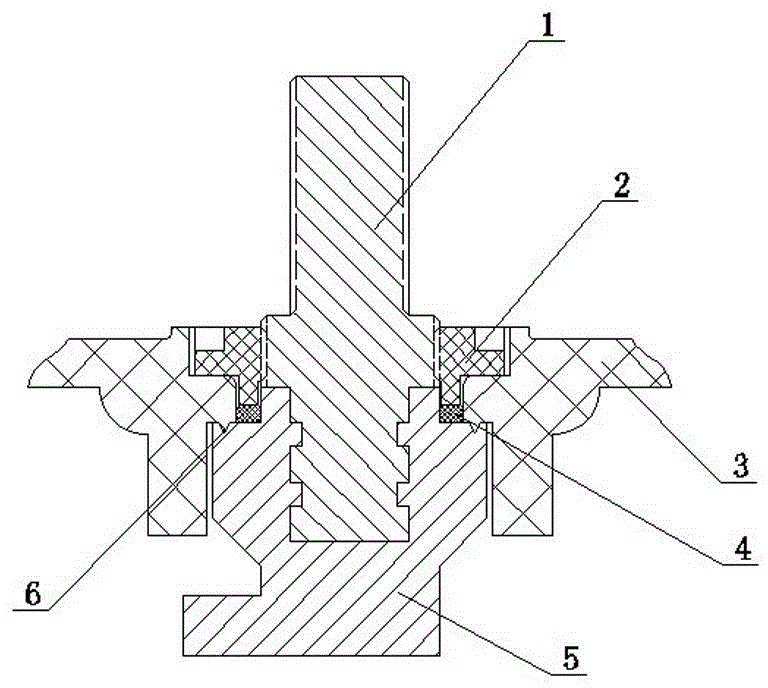

[0009] Referring to the accompanying drawings, the battery terminal 1 is connected with the lead pole 5 inside the battery, the fastener 2 is threadedly matched with the battery terminal 1, and there is a sealing ring at the junction of the fastener 2, the lead pole 5 and the battery upper cover 3 4, and the contact surface between the battery cover and the lead pole has a tapered and raised sealing line 6. Tighten the fastener 2 to compress the sealing ring 4, and insert the sealing line 6 into the end face of the lead pole 5 to play a double sealing role.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com