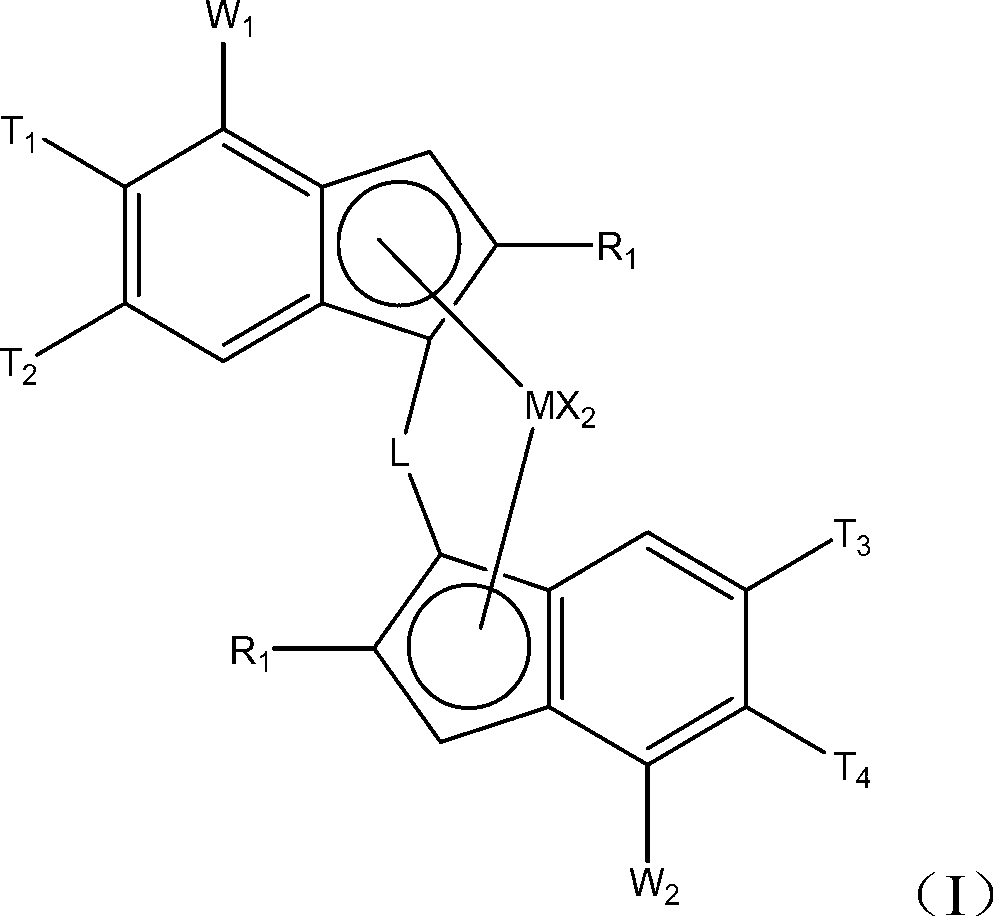

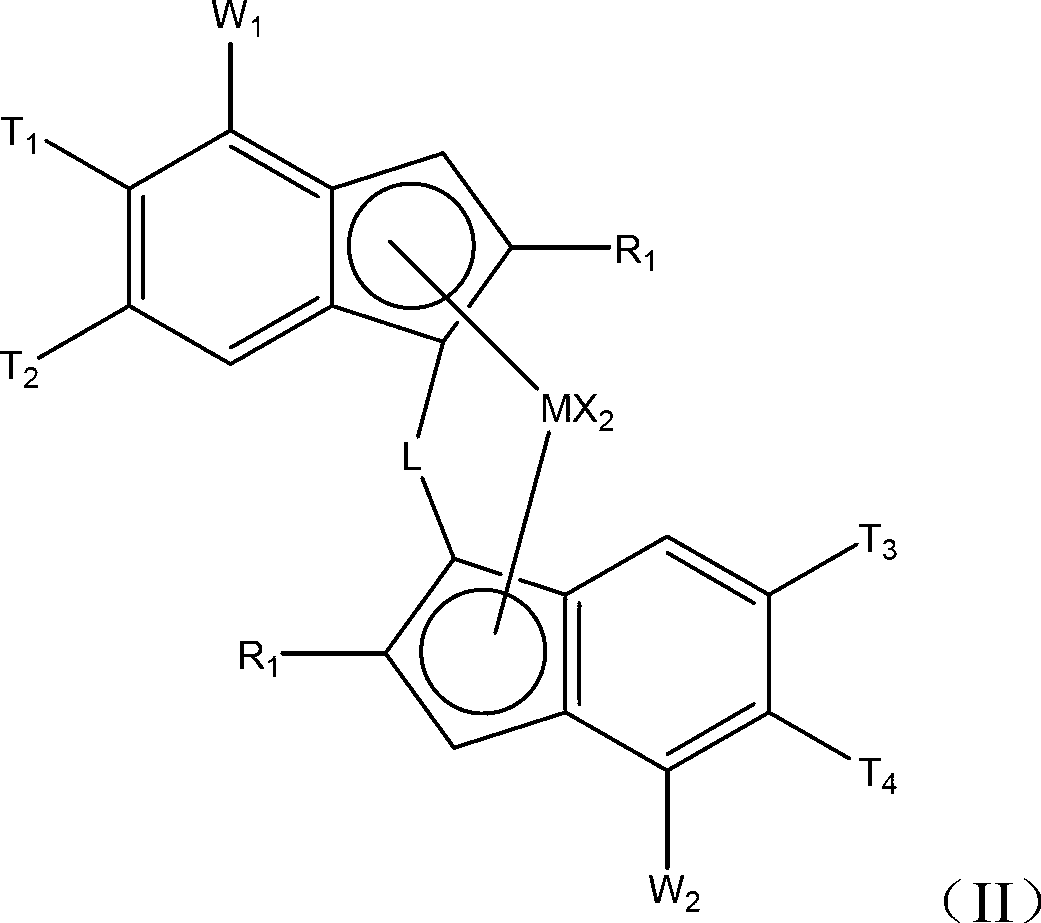

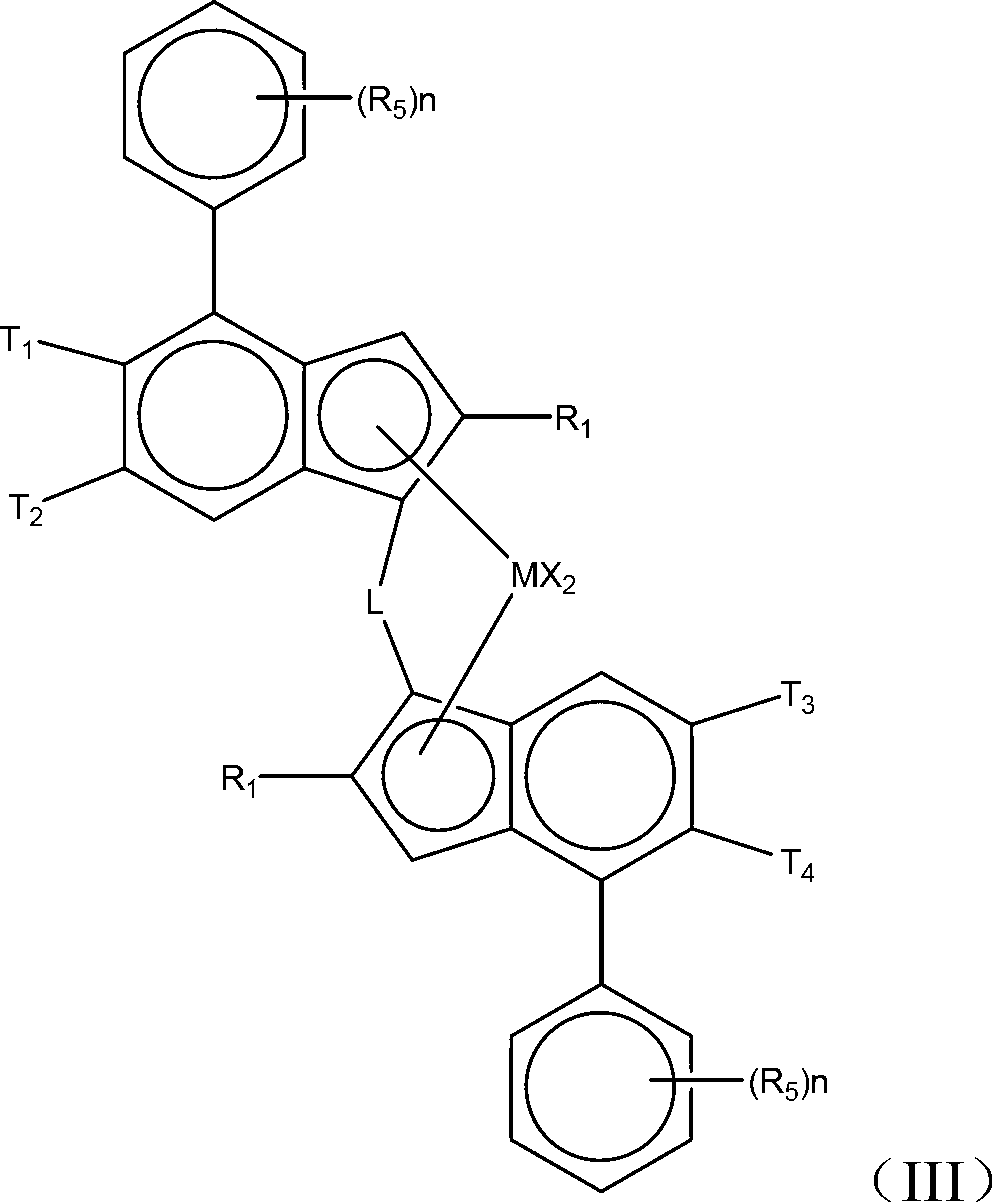

Solid particulate catalysts comprising bridged metallocenes

A technology of solid particles and catalysts used in the field of olefin polymerization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0226] Embodiment 1 (invention):

[0227] According to the procedure described in Example 5 of WO 2003 / 051934, using hexadecafluoro-1,3-dimethylcyclohexane as the continuous phase, acrylic perfluoroalkanes with different perfluoroalkyl chain lengths A mixture of ethyl ethyl esters as surfactant precursors, and rac-dimethylsilyl-bis(2-methyl-4-phenyl-5-methoxy-6-tert-butylindene-1 -base) zirconium dichloride as a metallocene to prepare a catalyst in the form of solid particles without an external support.

[0228] The detailed catalyst preparation was carried out as follows:

[0229] Inside the glove box, 80 μL of dry and degassed perfluoroalkylethyl acrylate was mixed with 2 mL of MAO in a septum bottle and reacted overnight (surfactant solution). The next day, 60.60 mg of metallocene was dissolved in 4 mL of MAO solution in another septum and stirred in the glove box (catalyst solution).

[0230] After 60 minutes, 4 mL of the catalyst solution and 1 mL of the surfactant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com