Fluidized bed furnace and waste processing method

A fluidized bed furnace, waste technology, applied in fluidized bed combustion equipment, incinerators, combustion methods, etc., can solve problems such as inability to obtain stable energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Hereinafter, an embodiment of the present invention will be described with reference to the drawings.

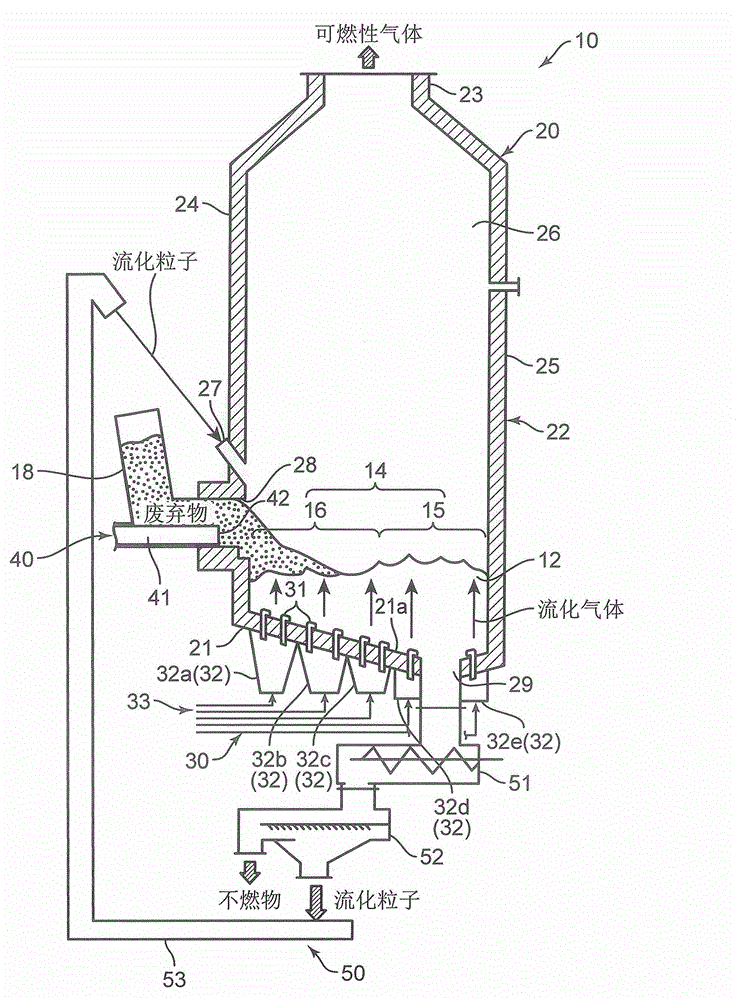

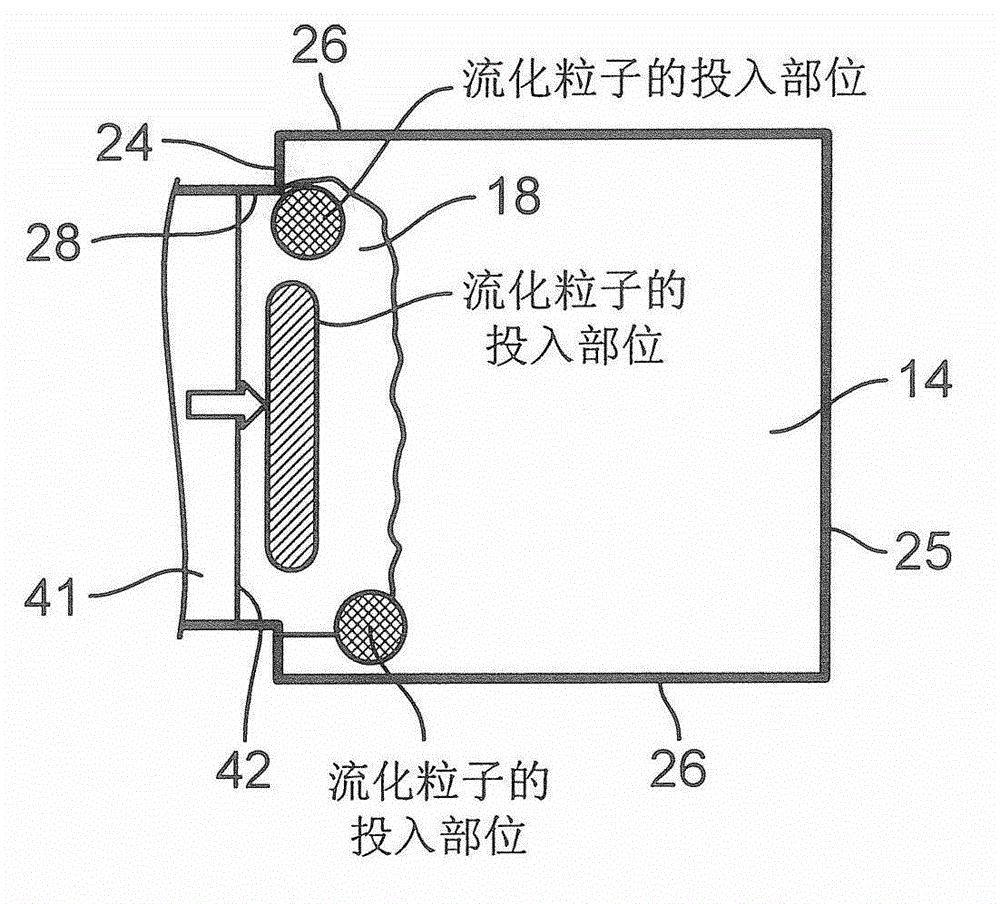

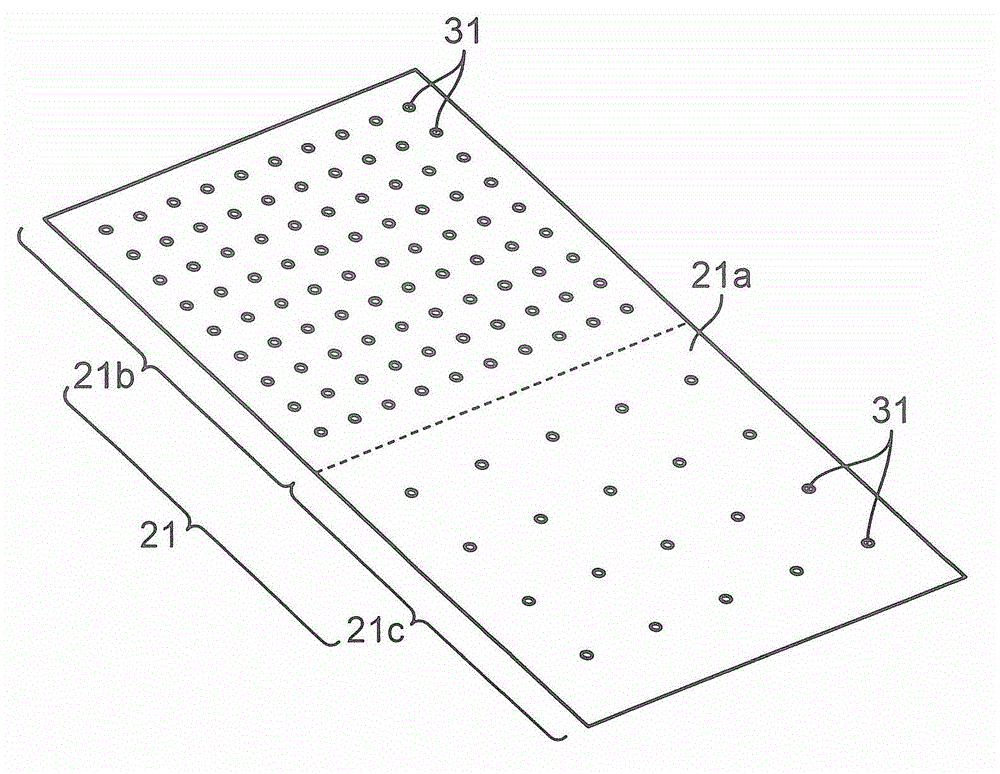

[0022] The fluidized bed furnace according to this embodiment heats waste with high-temperature fluidized particles, thereby extracting combustible gas from the waste. Such as figure 1 As shown, this fluidized bed furnace includes fluidized particles 12 , a furnace main body 20 , a gas supply unit 30 , a waste supply unit 40 , and a sand circulation device 50 .

[0023] The fluidized particles 12 are used to form a fluidized bed 14 inside the furnace main body 20 and to heat waste 18 . That is, the fluidized particles 12 heated to a high temperature by the combustion of a part of the waste 18 are mixed with the waste 18, and the waste 18 is gasified to generate a combustible gas. The fluidized particles 12 of the present embodiment are, for example, silica sand or the like.

[0024] The furnace main body 20 has fluidized particles 12 inside, and combustible gas is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com