Battery connection member and battery connection body

A battery connection and component technology, which is applied in the field of battery connection parts and battery connectors, can solve the problems of increased mold costs and achieve the effect of reducing mold costs and material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

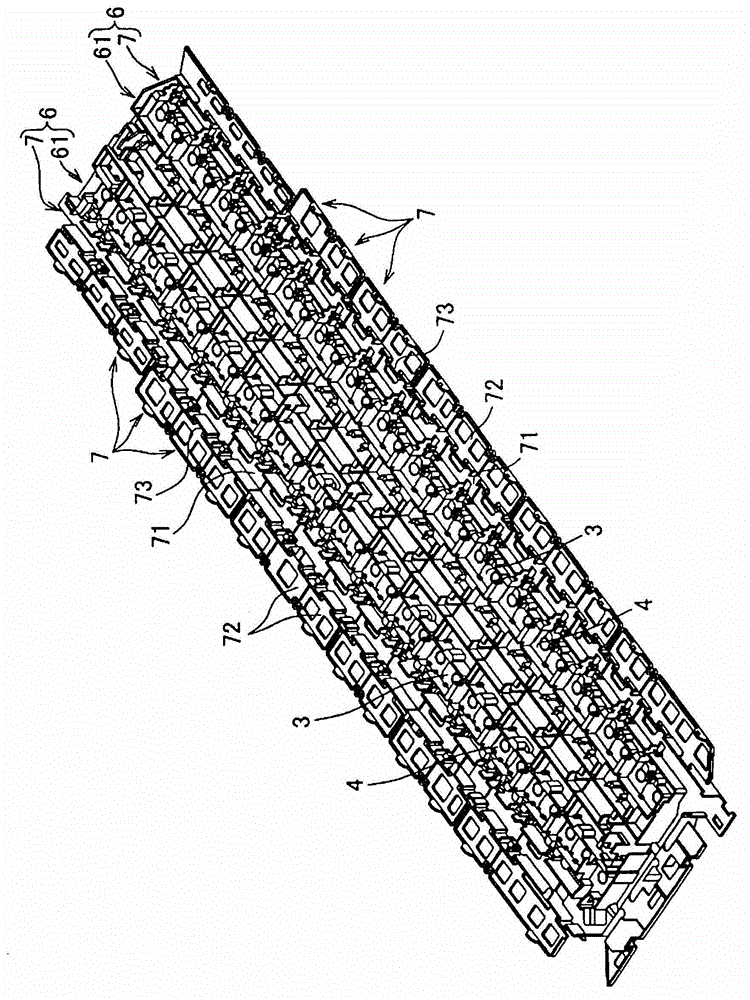

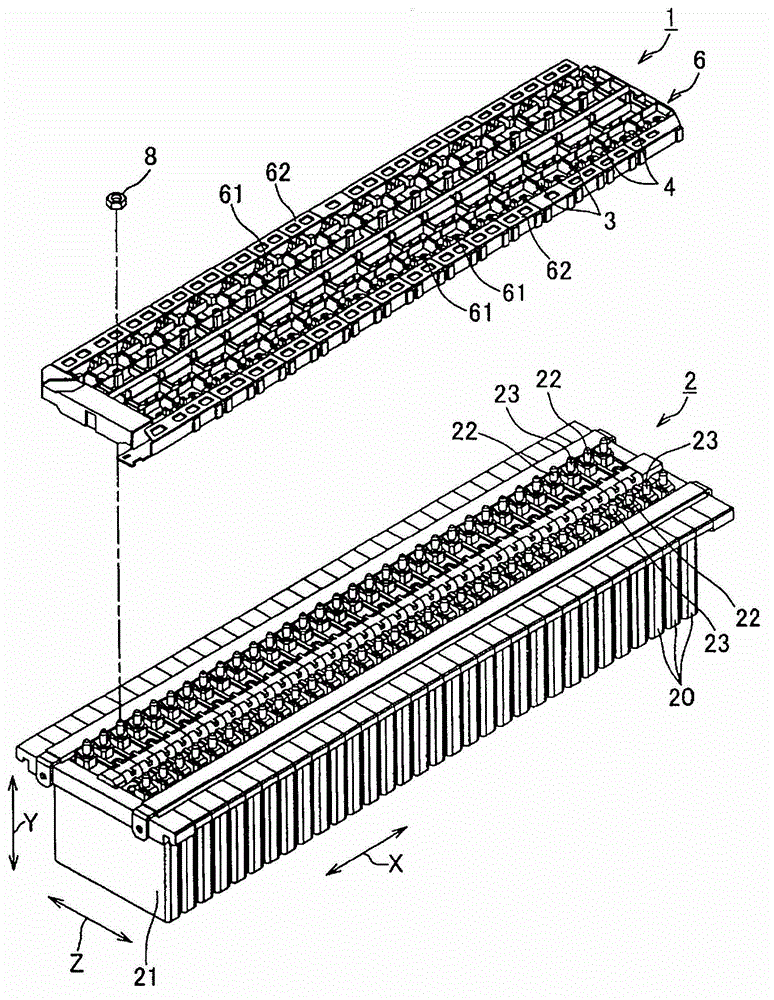

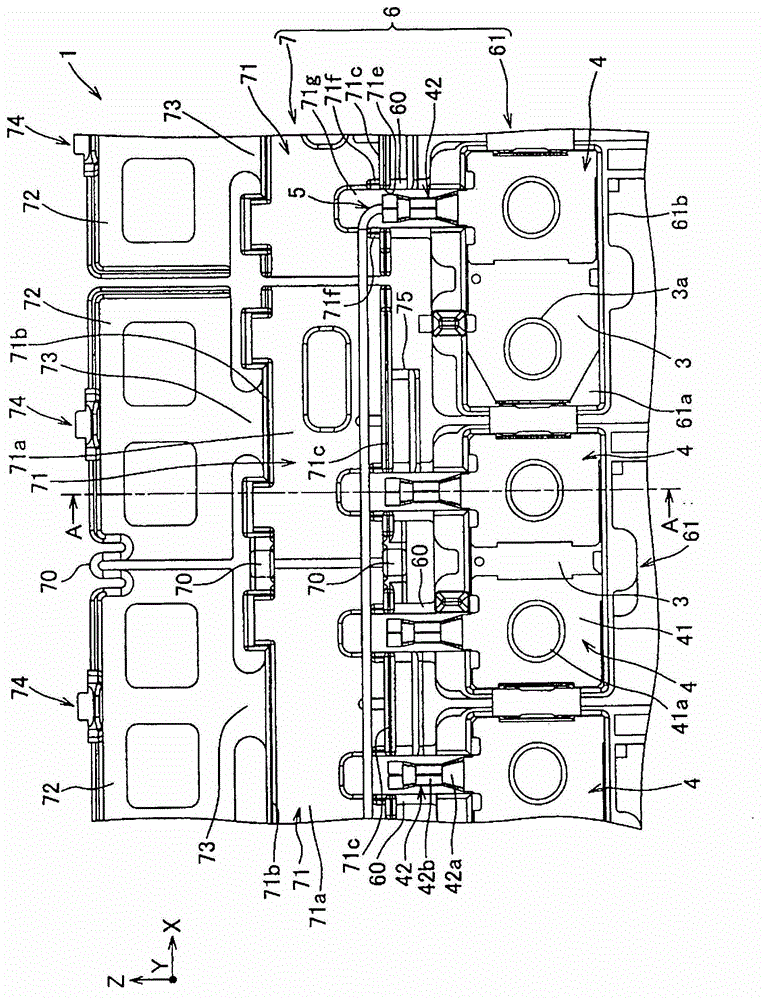

[0026] Below, refer to Figure 1 to Figure 5 The accompanying drawings illustrate one embodiment of the battery connecting member and the battery connecting body according to the present invention.

[0027] Such as figure 1 , 2 As shown, the battery connector 1 of the present invention is mounted on a battery assembly 2 to constitute a power supply device. In addition, the power supply unit is mounted on an electric vehicle that runs using an electric motor, a hybrid vehicle that runs on an engine and an electric motor, and the like, and is a component that supplies electric power to the electric motor. In addition, the battery assembly is formed by alternately stacking batteries (prismatic batteries) having a positive electrode at one end and a negative electrode at the other end.

[0028] First, the battery assembly 2 such as figure 2 As shown, there are a plurality of batteries 20 and a fixing member (not shown) that overlaps and fixes the plurality of batteries 20 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com