Golf club head with replaceable assembly

A golf club head and replaceable technology, which is applied to golf balls, golf clubs, rackets, etc., can solve the problem that the lie angle and face angle of the club head are difficult to develop and produce in a variety of product specifications, and cannot be supplied and used at a reasonable price to reduce mold costs, prevent sports injuries, and reduce shock waves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

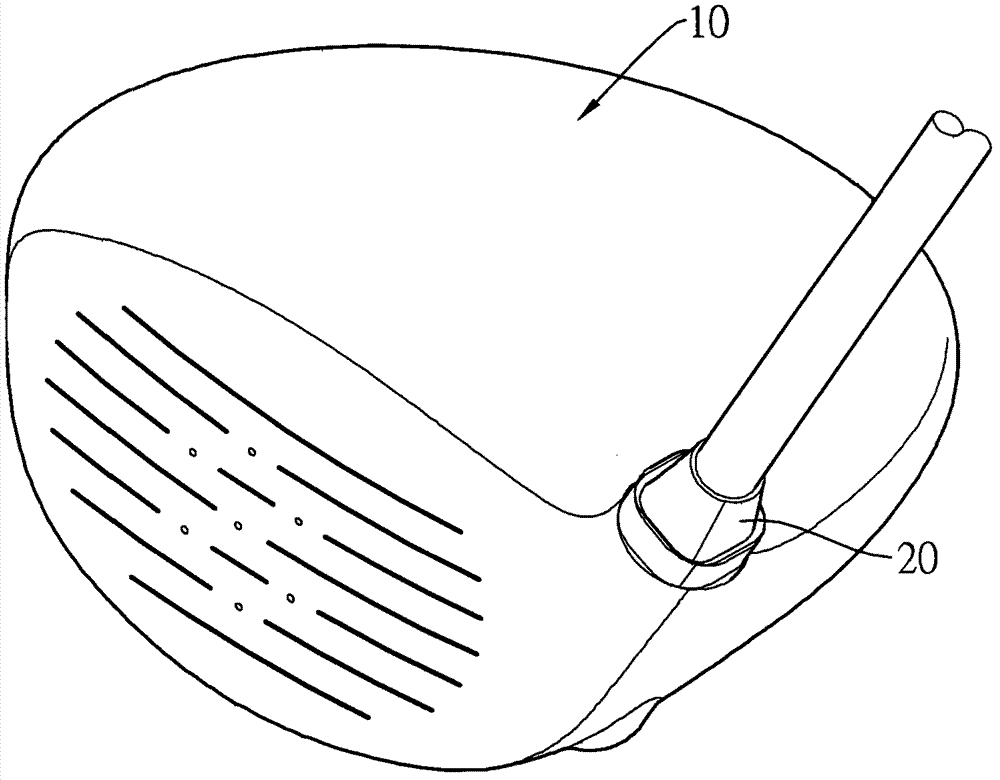

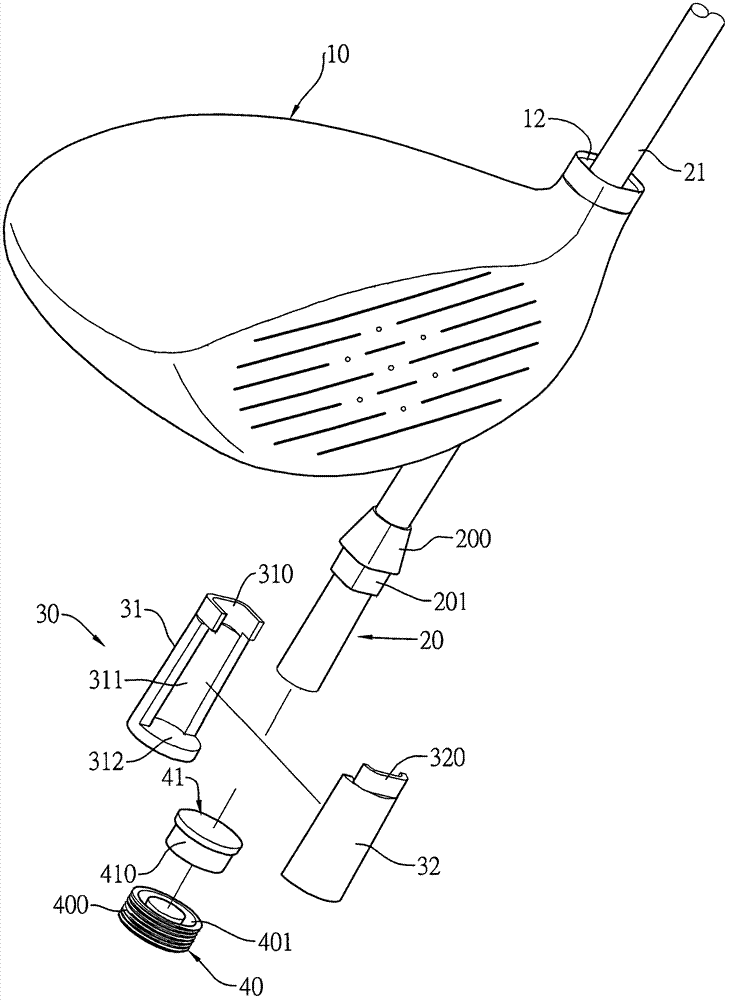

[0053] The present invention is a golf club head with interchangeable components, see figure 1 and figure 2 As shown, it includes a ball head body 10, a shaft joint 20, a positioning pipe 30 and a screw 40;

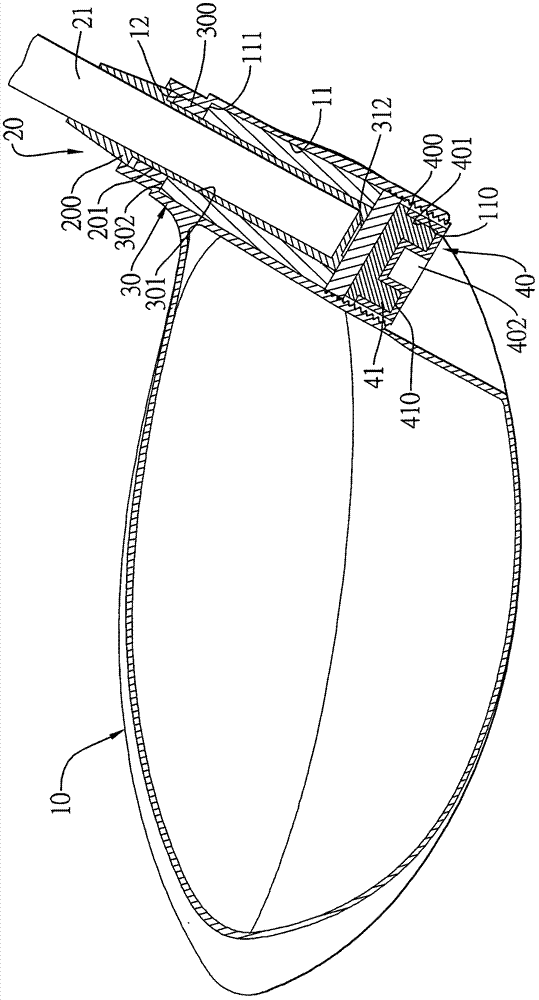

[0054] Please refer to image 3 and Figure 4 As shown, the ball head body 10 is a club head formed by precision casting, and a mounting hole 11 is perforated on one side of the ball head body 10, and the two ends of the mounting hole 11 respectively pass through the top of the ball head body 10 and At the bottom, an internal thread 110 is provided on the inner wall of the bottom end of the mounting hole 11. In the specific embodiment shown in the figure, the diameter of the mounting hole 11 is gradually increasing from the top to the bottom. Please Cooperate with reference Figure 5As shown, the inner hole wall at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com