Integral connection structure of vehicle drive system, brake system and frame and calipers support

A caliper bracket and braking system technology, applied in the field of caliper brackets, can solve the problems of reducing the convenience of vehicle disassembly, increasing the risk of vehicle design, and difficult layout of the vehicle, achieving broad market application prospects and involving fewer parts , the effect of small layout difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing, the present invention will be further explained:

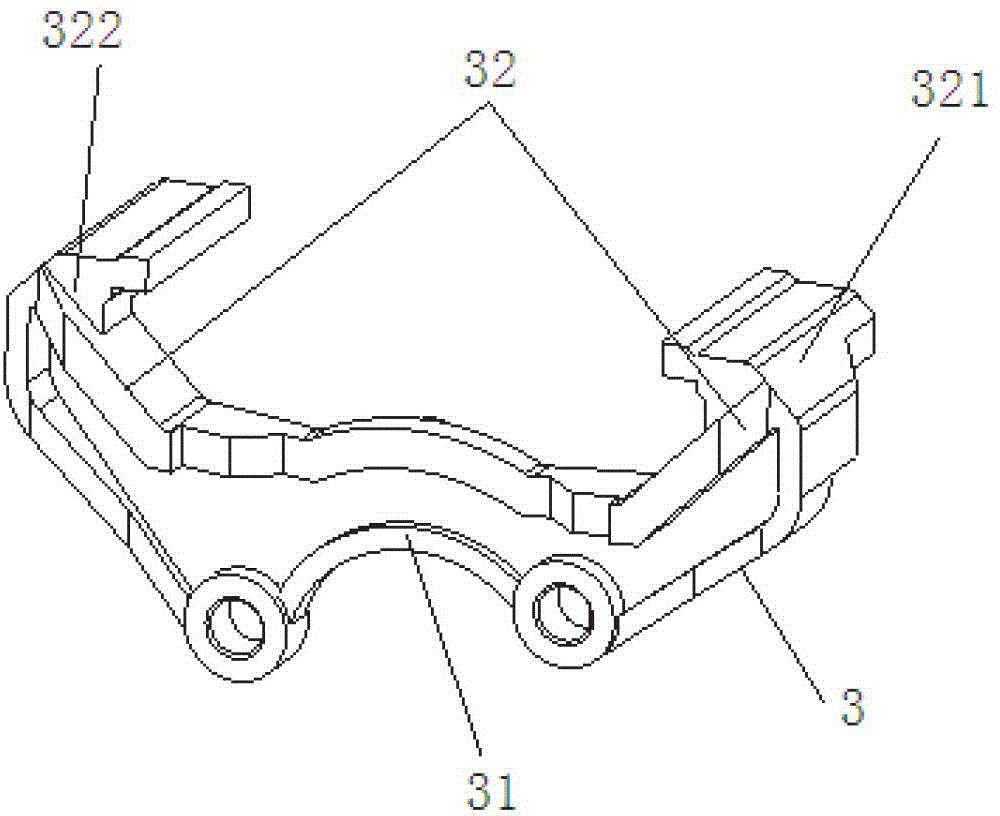

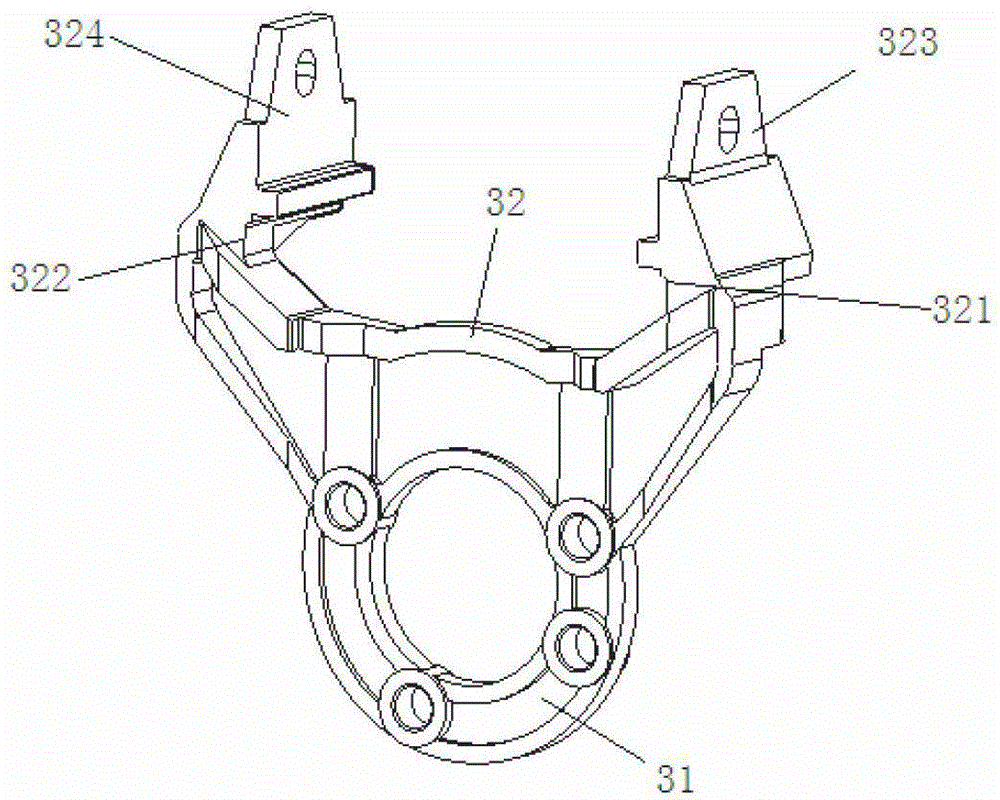

[0017] refer to image 3 , the caliper bracket 3 is integrally made by the final reducer end 31 and the brake end 32, the final reducer end 31 is a ring end, and the brake end 32 includes an upper guide groove 321 and a lower guide groove frame 322, so The upper guide groove 321 is connected with the upper tail portion 323 , and the lower guide groove 322 is connected with the lower tail portion 324 .

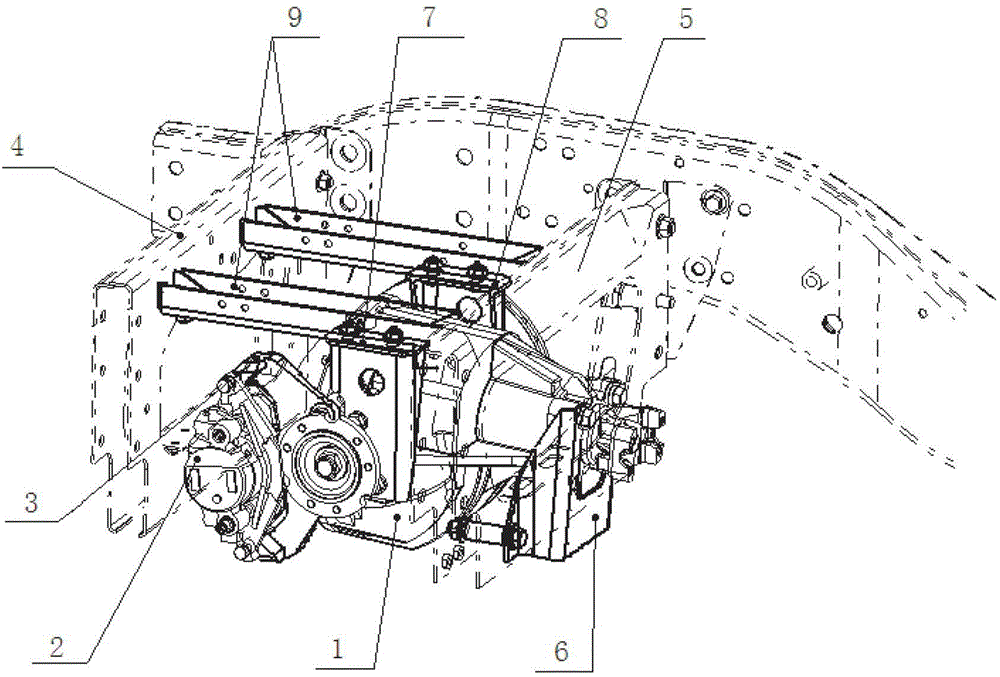

[0018] refer to Figure 4 , during installation, the two sides of the main reducer assembly 1 are respectively socketed and fixed with the main reducer ends 31 (that is, the ring ends) of the two caliper brackets 3, and the upper tail 323 of the brake end 32 of the left caliper bracket 3 is connected to the The front beam 4 of the vehicle frame is fixedly connected, and the lower tail portion 333 is fixedly connected with the front beam 4 of the vehicle frame through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com