Electroplating crimping die

A technology of crimping molds and compression molds, which is applied in jewelry and other fields, can solve problems such as high cost, efficiency constraints, and complex structures, and achieve the effect of real-time quality inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

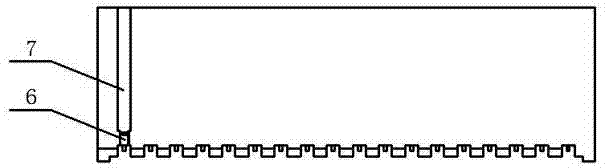

[0010] Such as figure 1 As shown, the electroplating crimping die described in the embodiment of the present invention includes a die bar, the die bar is rectangular, and several uniformly arranged briquetting blocks are arranged at the lower part of the die bar. Electroplating joints 6 are arranged between the blocks, and corresponding to each electroplating joint, a through hole 7 through which a welding torch can pass is provided inside the molded strip.

[0011] Positioning structures are provided at both ends of the molding strip.

[0012] The electroplating and crimping mold provided by the invention can perform electroplating and cutting operations on multiple triodes at one time, which can be realized by manual operation, without the need for large-scale equipment, and can check the quality of the compression mold in real time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com