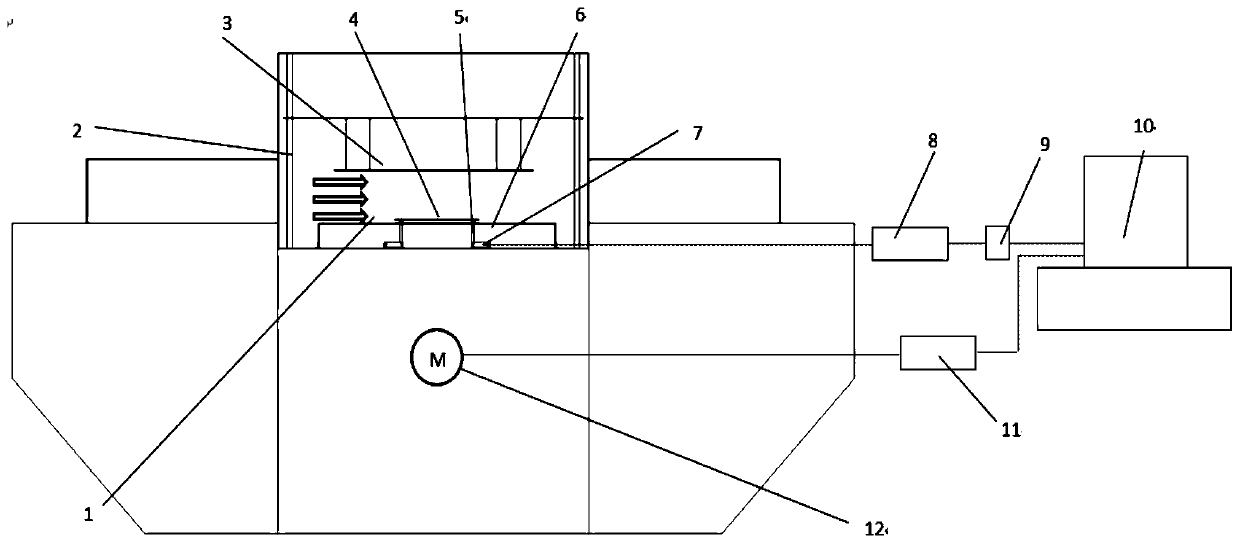

On-line weighing control system of radio frequency-hot air combined drying equipment

A technology that combines drying and control systems, used in lighting and heating equipment, material weighing, drying of solid materials, etc. problems, to achieve better quality of dried products, improve drying rate and energy utilization efficiency, and improve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The present invention will be described in detail below by taking combined radio frequency-hot air drying of corn seeds as an example. This example is only a preferred embodiment of the present invention, but not a limitation of the present invention. Concrete steps are as follows: first, quality is 2kg, and the corn seed that initial water content is 30% is placed on weighing tray 4, and input the initial mass and initial water content of corn seed in computer control system; Secondly, Set the initial pole plate spacing on the radio frequency equipment control panel to be 160mm, the initial wind speed is 1m / s, turn on the radio frequency equipment, and in the intelligent weighing module program in the computer control system 10, it can be set to read the quality of the material once in 10s. After drying for a period of time, the system can calculate whether the drying rate of corn seeds has changed during this period of time. When the drying device is in the constant dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com