Fully sealed inhaul cable and utilization method thereof

A fully sealed and cable-body technology, applied in the field of cables, can solve problems such as failure of protective measures and aging of sealing materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

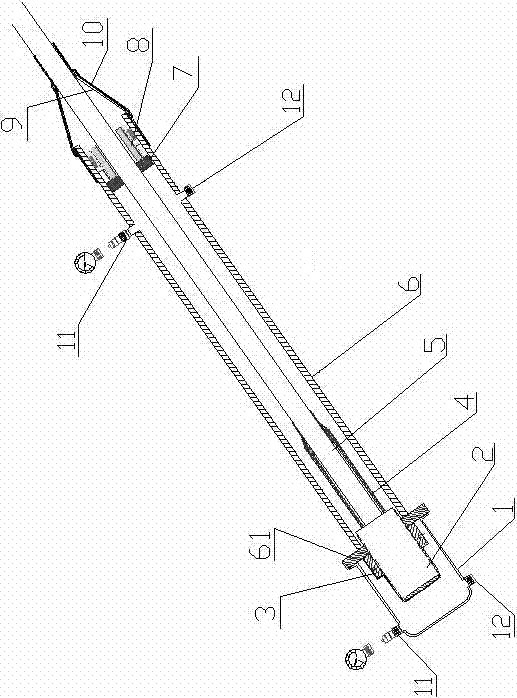

[0012] A fully sealed cable, including an anchor guard 1, a quick connector 11, an air outlet plug 12, an anchor 2, a nut 3, a connecting cylinder 4, a cable body 5, a pre-embedded cable guide 6, and an anchor plate 61 , sealing material 7, damper 8, protective liner 9 and heat-shrinkable protective sleeve 10, such as figure 1 As shown, the specific structure is: one end of the cable body 5 is inserted into the connecting tube 4 and inserted into the anchor cup of the anchor tool 2 through the connecting tube 4, and the anchor head of the anchor tool 2 is inserted into the embedded cable guide 6 and is inserted from the embedded cable guide 6. The anchor 2 and the embedded cable conduit 6 are connected by a nut 3, the other end of the cable body 5 fixes the damper 8 and passes through the other end surface of the embedded cable conduit 6, and the damper 8 is lined on the Between the cable body 5 and the pre-buried cable guide 6, there is also a sealing compound 7 between the c...

Embodiment 2

[0029] A fully sealed cable, including an anchor guard 1, a quick connector 11, an air outlet plug 12, an anchor 2, a nut 3, a connecting cylinder 4, a cable body 5, a pre-embedded cable guide 6, and an anchor plate 61 , sealing material 7, damper 8, protective liner 9 and heat-shrinkable protective sleeve 10, the specific structure is as follows figure 1 Shown, with embodiment 1 same.

[0030] The installation steps of this embodiment are the same as those of Embodiment 1.

[0031] When the present embodiment is used, proceed as follows:

[0032] a. Connect the quick connector 11 on the embedded cable conduit 6 with the hygrometer, thereby realizing the monitoring of the humidity in the embedded cable conduit 6;

[0033] b. Connect the quick connector 11 on the embedded cable conduit 6 to the blower, and use the blower to fill the embedded cable conduit 6 with dry air or inert gas;

[0034] c. Open the air outlet plug 12 on the embedded cable conduit 6, and fill the embedd...

Embodiment 3

[0036] A fully sealed cable, including an anchor guard 1, a quick connector 11, an air outlet plug 12, an anchor 2, a nut 3, a connecting cylinder 4, a cable body 5, a pre-embedded cable guide 6, and an anchor plate 61 , sealing material 7, damper 8, protective liner 9 and heat-shrinkable protective sleeve 10, the specific structure is as follows figure 1 Shown, with embodiment 1 same.

[0037] The installation steps of this embodiment are the same as those of Embodiment 1.

[0038] When the present embodiment is used, proceed as follows:

[0039] a. Connect the quick connector 11 on the anchorage protective cover 1 with the hygrometer, so as to realize the monitoring of the humidity in the anchorage protective cover 1;

[0040] b. Connect the quick connector 11 on the anchor guard 1 to the blower, and use the blower to fill the anchor guard 1 with dry air or inert gas;

[0041] c. Open the air outlet plug 12 on the anchor protective cover 1, and fill the anchor protective co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com