Fiber laser health monitoring method

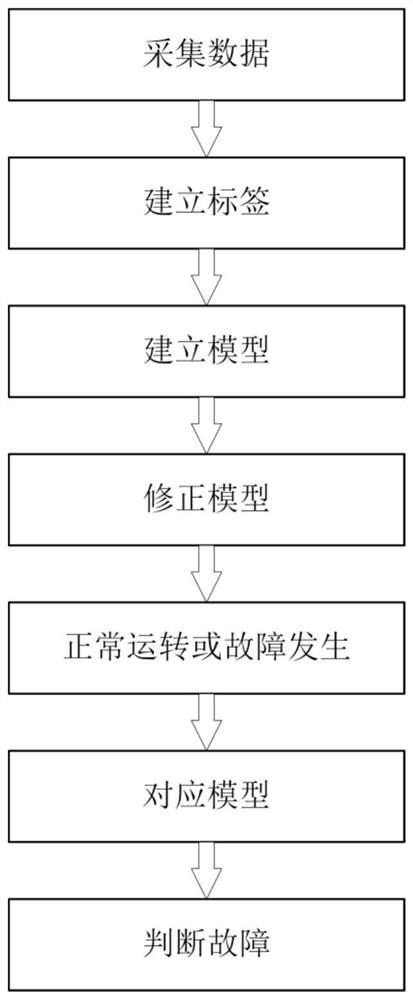

A fiber laser and health monitoring technology, which is applied in the direction of laser monitoring devices, lasers, optical instrument testing, etc., can solve problems such as abnormal rise, failure of fiber laser power supply, optical path failure monitoring, failure of temperature and humidity monitoring, etc., to achieve convenient The effect of mastering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

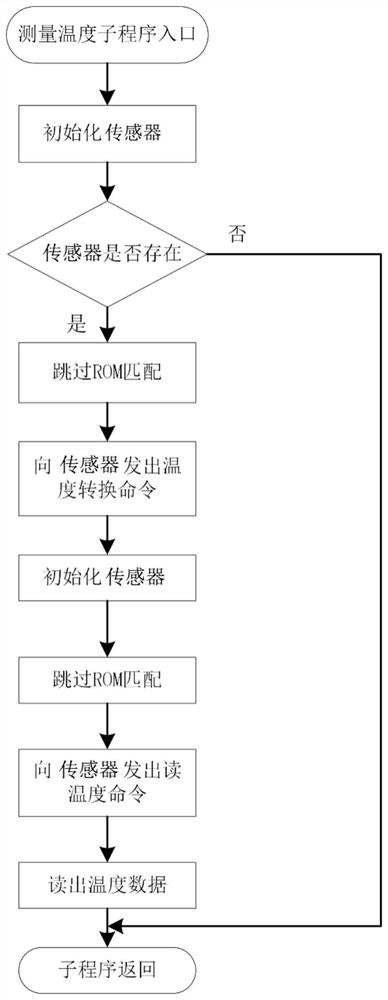

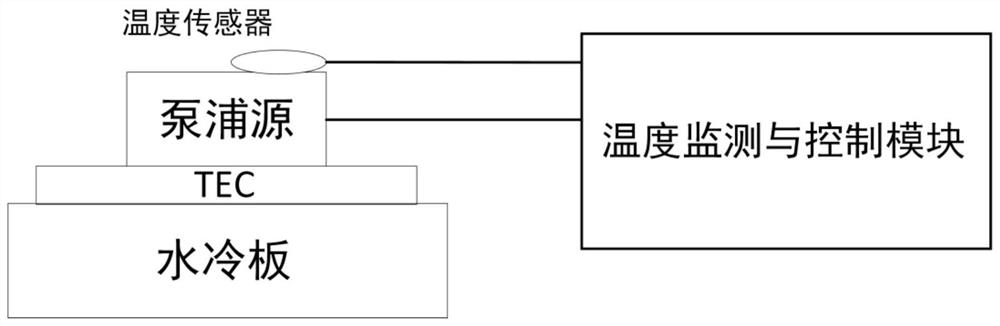

[0064] Firstly, the measured data set of the pump source temperature is collected for the fiber laser. The pump source temperature acquisition consists of several modules: the pump temperature parameter acquisition module is used to collect the current pump source temperature through one or more sensors to generate one or more collected temperatures. The microprocessor module is connected with the temperature parameter acquisition module, and is used for analyzing one or more collected temperatures and generating corresponding control instructions. The control output module is connected with the microprocessor module and is used for generating a driving signal according to the control instruction of the microprocessor module. The power supply module is used for supplying power to the temperature parameter acquisition module, the control output module and the microprocessor module.

[0065] For the temperature acquisition process, refer to the attached figure 2 , measuring t...

Embodiment 2

[0072] The fiber laser pump source works by direct injection of carriers, and the stability of the injection current has a direct impact on the output of the laser. Factors such as surge impact, electrostatic breakdown, and forward overcurrent can easily damage the laser. The driving current of the pump source is a constant current with small ripple and few glitches, and the working safety of the pump source needs to be considered at the same time.

[0073] Acquisition of driving current: The current acquisition circuit uses the method of converting series resistance into voltage for measurement, collects the voltage in the circuit through a 50mΩ resistance, and converts the collected tiny voltage signal into a voltage signal range that the microprocessor can handle through the op amp . An operational amplifier is used that accurately amplifies differential input voltages with positive high common-mode voltages greater than 500V. The collected voltage divided by the resistan...

Embodiment 3

[0079]The oscillator of the fiber laser controls the excitation of the fiber according to the input laser output command value or current command value to obtain the desired laser output. The output power of the oscillator is the most important parameter of the oscillator, which seriously affects the working state of the laser.

[0080] Oscillator output power acquisition: According to the structure of the fiber laser system, the sampling optical path of the laser output power real-time monitoring device involved is mainly composed of the main optical path sampling mirror and optical attenuator. The sampling optical path is shown in the attached Figure 4 shown.

[0081] In order to achieve real-time monitoring of laser power without affecting the output laser used in the work, a high-transmittance beam splitter with an angle of 45° to the output light is added to the main optical path of the output light, and the tiny reflection of the sampling mirror is used The light sampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com