Assembling and lifting method of half-span skeleton of tied arch bridge

A tie-rod arch bridge and hoisting method technology, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of complex arch rib stress and deformation, affecting the smooth passage of water channels, and excessive construction time, so as to shorten the construction period, Accuracy control is easy and the effect of ensuring construction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1 Half-span hoisting tie rod arch bridge

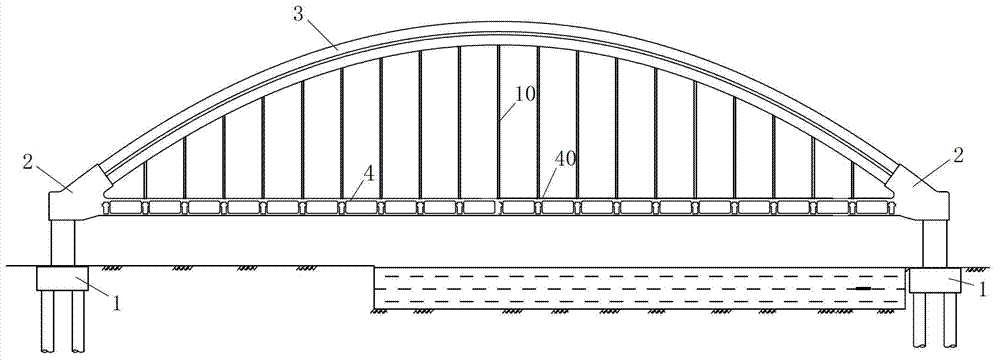

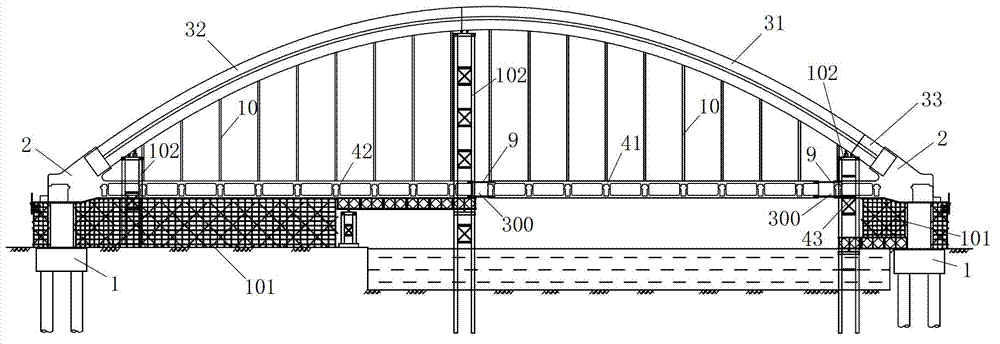

[0037] The half-span hoisting tie-bar arch bridge of the present embodiment, as figure 1 and figure 2As shown, it includes bridge piers 1 located on both banks of the river, arch feet 2 located on bridge piers 1, arch ribs 3 and bridge deck stiff skeleton 4 that span across the river and are connected to the arch feet 2 on both sides of the river, and erected on the The bridge deck 40 on the bridge deck stiff frame 4. The stiff frame 4 of the bridge deck is located directly below the arch rib 3 . The arch rib 3 is formed by welding and fixing a plurality of arch rib segment prefabricated end to end, and is divided into a first arch rib segment 31 , a second arch rib segment 32 and a third arch rib segment 33 . One end of the second arch rib section 32 is embedded in the arch foot 2 away from the river bank, and is located above the land. One end of the third arch rib section 33 is embedded in the arch foot 2 clo...

Embodiment 2

[0039] Embodiment 2 Assembling and hoisting method of half-span frame of tied arch bridge

[0040] The method for assembling and hoisting the half-span skeleton of the tie-bar arch bridge of the present embodiment is the construction method of the half-span hoisting tie-bar arch bridge of Embodiment 1, and the specific steps are as follows:

[0041] A. Set tire racks on the bank near the bridge to be erected. The first arch rib section 31 and the first bridge deck stiff skeleton section 41 are assembled and formed.

[0042] Assembling and forming of the first arch rib section 31: firstly transport the prefabricated arch rib section to the construction site. like Image 6 and Figure 7 As shown, the tire frame is set on the bank of the construction site according to the shape and size of the first rib section 31, and the prefabricated parts of the rib section are erected horizontally on the tire frame to assemble the first rib section 31. During assembly, the shape and siz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com