Lifting hanger for unitized curtain wall sheet

A unit curtain wall and plate technology, applied in the processing of building materials, construction, building construction, etc., can solve problems such as installation and disassembly inconvenience, plate deformation, and affecting the normal use of glass plates, and achieve fast and convenient assembly. The effect of reasonable force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

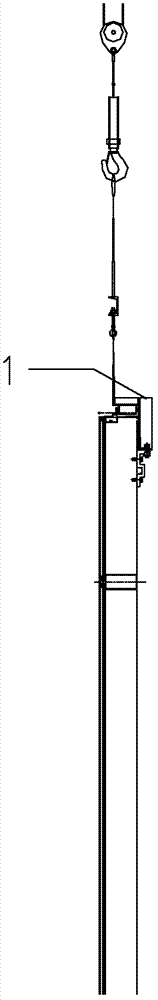

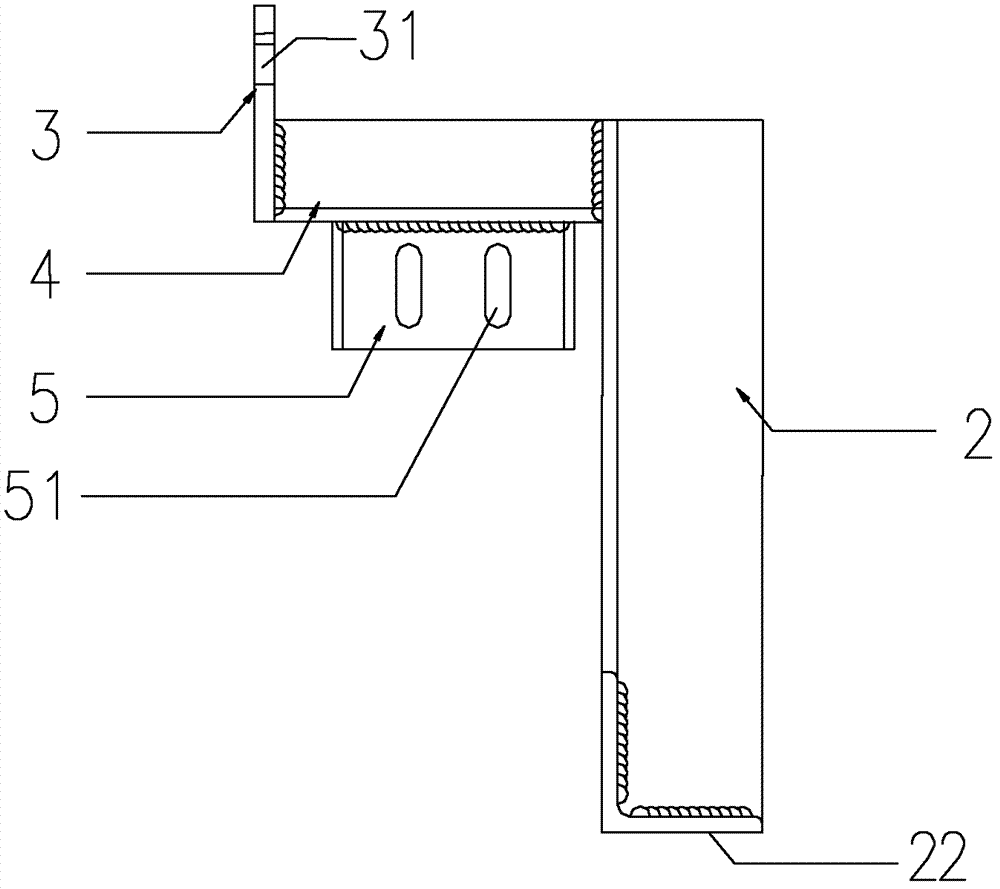

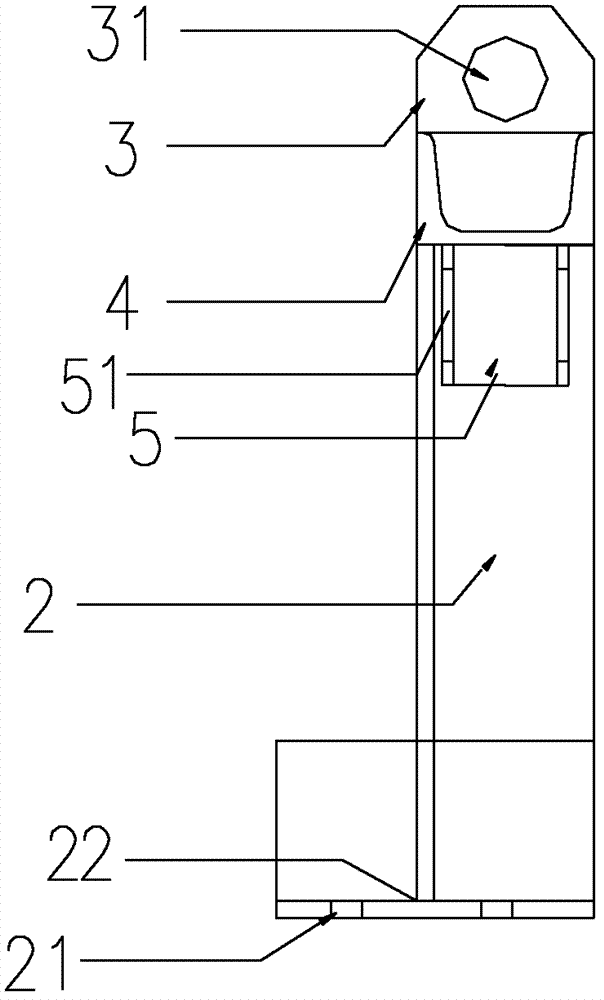

[0016] Such as figure 1 As shown, the hoisting pendant 1 is used to connect the hoisting equipment and the hanging code of the unit curtain wall panels. Its specific structure is as Figure 2~4 As shown, the lifting pendant 1 includes a connecting steel plate 3, an angle steel 2, a channel steel 4 and a square pass 5, the connecting steel plate 3 is arranged at one end of the channel steel 4, and the connecting steel plate 3 has a slot 31 for connecting the lifting equipment. The angle steel 2 is arranged at the other end of the channel steel 4, and the lower end of the angle steel 2 is provided with a connecting plate 22 for connecting the hanging code of the unit curtain wall panels. The connecting plate 22 is provided with a slot 21, and the hanging code of the unit curtain wall panels is hung In the slot 21, the square pass 5 is arranged under the channel steel 4, and the side wall of the square pass 5 is provided with a slot 51. The pendant can bear the weight of the uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com