Hollow type liquid crystal television set base

A technology for LCD TVs and substrates, which is applied in the direction of supporting machines, mechanical equipment, machine tables/supports, etc., which can solve the problems of heavy base weight, short service life, and high manufacturing costs, so as to achieve enhanced applicability, reduce production costs, and ensure load bearing intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

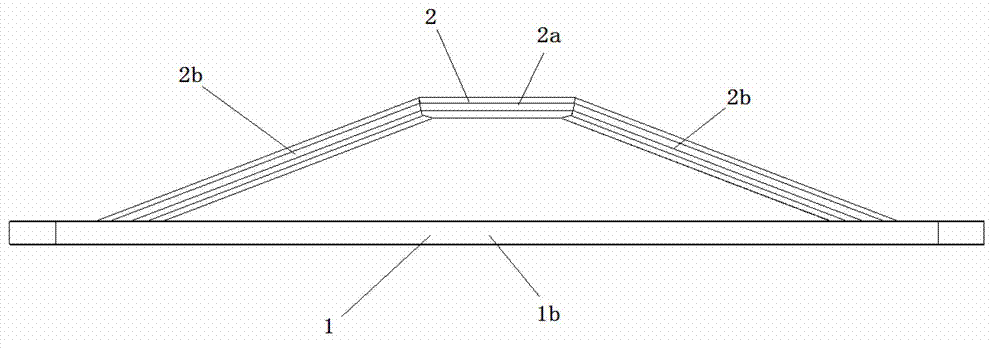

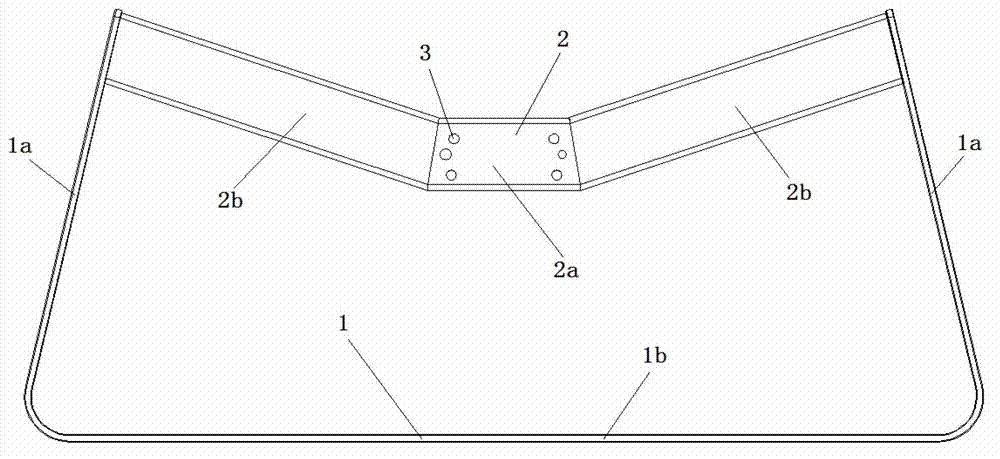

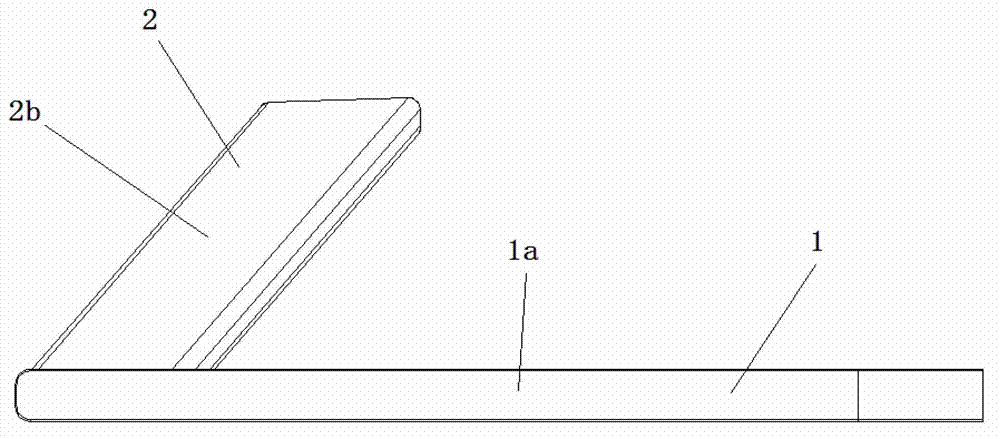

[0022] Example: Combine Figure 1 to Figure 5 As shown, the hollowed-out LCD TV base provided by the present invention is composed of a base and a support frame fixed on the base as in the conventional technology, and the improvement of the present invention is that the base is bent from a flat iron bar. The U-shaped member 1 is formed, and the support frame is a bridge-shaped member 2 composed of a top edge 2a made of a square iron pipe and two hypotenuses 2b symmetrically welded to its two sides and also made of a square iron pipe. The bottoms of the two hypotenuses 2b of the bridge-shaped member 2 are respectively welded and fixed to the inner surfaces of the ends of the two opposite sides 1a of the U-shaped member 1 . Six positioning holes 3 for passing screws (not shown in the figure) to fix the LCD TV A are symmetrically opened on the top edge 2a of the bridge member 2 .

[0023] Moreover, in this embodiment, the two opposite sides 1a of the U-shaped member 1 are inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com