Automatic production system of rotor

A production system and rotor technology, applied in the field of automation systems, can solve problems such as low efficiency, inability to use, poor practical performance, etc., and achieve the effects of accurate work efficiency, reduced use of manpower, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

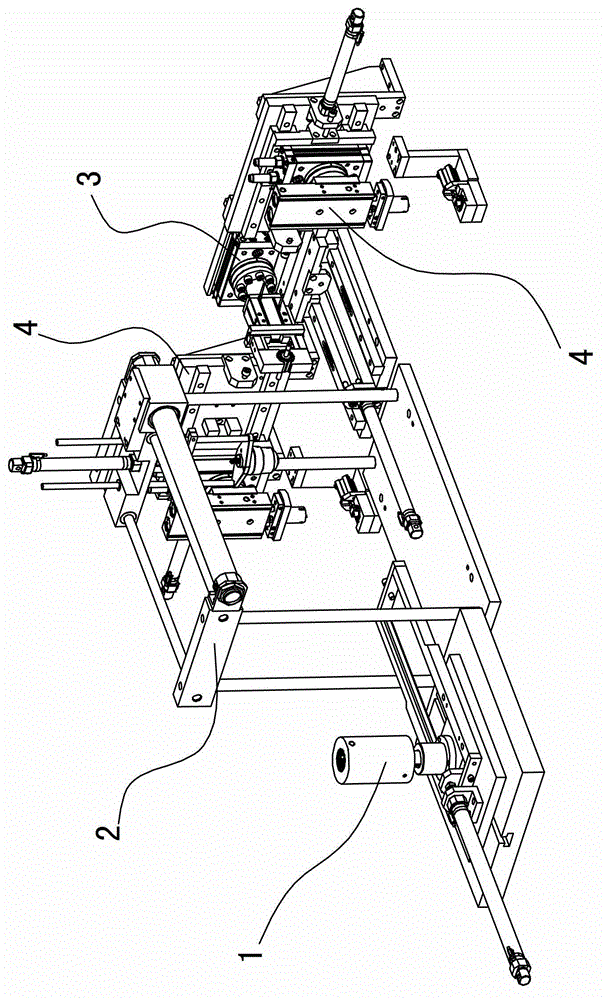

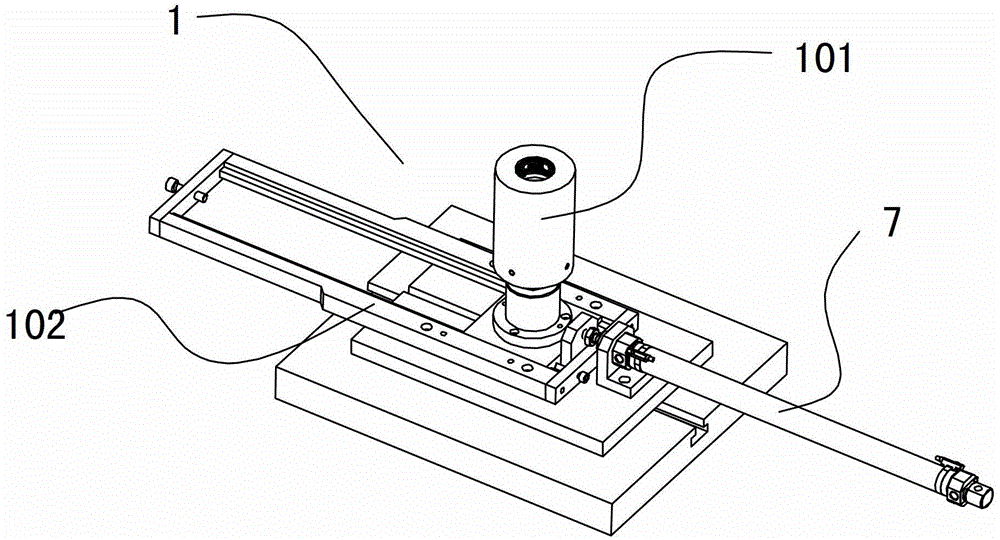

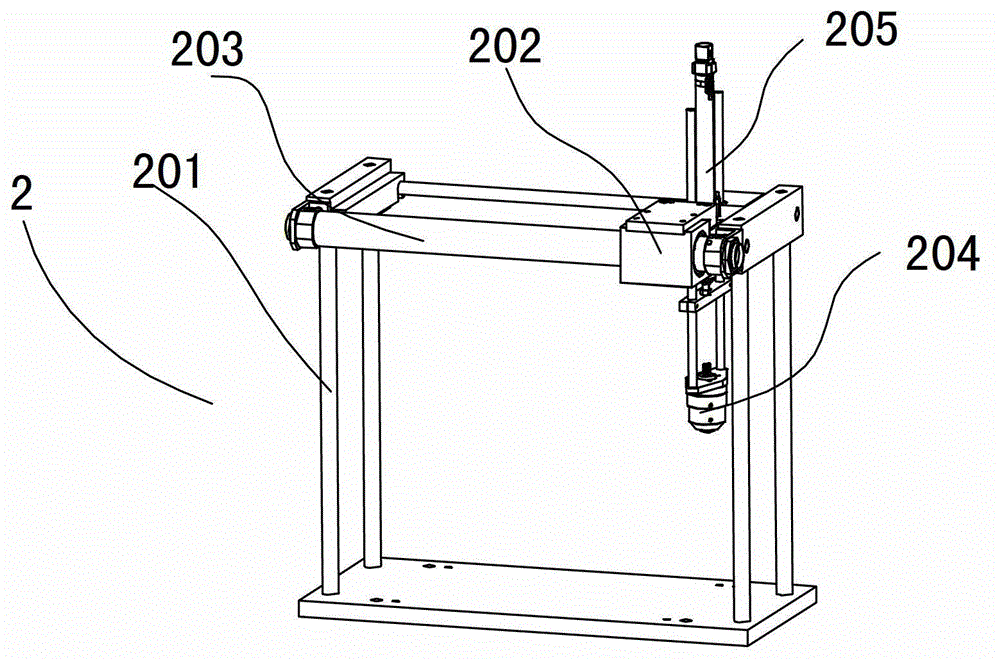

[0043]The rotor automatic production system includes a shaft pressing machine, an end plate pressing device, a commutator pressing device, a paper insertion machine, and a control device. The shaft pressing machine and the paper insertion machine are common mechanisms, so they are not shown in the figure. shown in the figure; the rotating shaft pressing machine is installed in front of the end plate pressing device, and the end plate pressing device includes an end plate pressing mechanism 4 and a rotating shaft rotation fixing mechanism 3; two end plate pressing mechanisms 4 are arranged symmetrically on the rotating shaft Both sides of the fixing mechanism 3; the commutator press-in device, including the commutator material guide mechanism 10, the commutator press-in mechanism 15, the rotating shaft rotation fixing mechanism 3, and the support seat 18; the movement of the commutator material guide mechanism 10 The end of the stroke just corresponds to the start end of the mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com